- Home

- Forums

- The Entrance Gate- Welcome to Competition Diesel

- Competition Events and Get-Togethers

- NHRDA

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

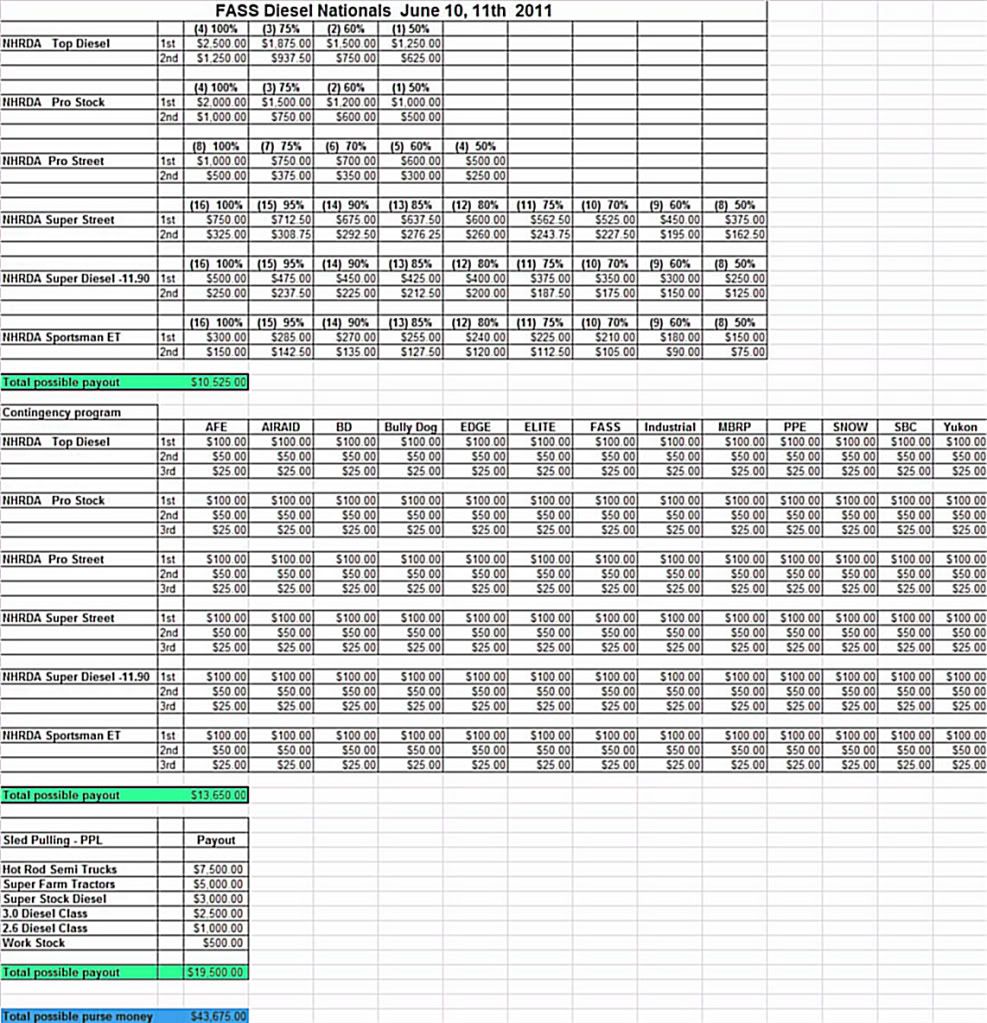

FASS Diesel Nationals - June 10,11 2011

- Thread starter NHRDA

- Start date

DIESEL_POWER

NGM Diesel

40k is a big purse.:rockwoot:

Can you post a payout breakdown.

Thanks!

Can you post a payout breakdown.

Thanks!

JohhnyFoxtrot

need a trailer

I'll be there again this year.

Redneck6.0L

New member

we"ll be there

dirttymaxx

New member

can you post a link to the sled pulling rules?

1badharley

New member

FCDP will make the trip with the ranger, cant wait. looks like its going to be a great event.

rocracing

NHRDA President

can you post a link to the sled pulling rules?

We are in Phoenix for first event but got rules from ppl and they will be same as ts and scheids we will get posted when we get back in town

rocracing

NHRDA President

can you post a link to the sled pulling rules?

Sorry we have been on the road last 2 weeks for our season opener in Phoenix.

Here are proposed rules for 2.6 class from the PPL. We will get them confirmed and posted later this month

As far as I know these same rules will apply at TS and Scheids this year.

2.6 Diesel 4X4 Truck

Weight breaks2.6: 8000 lbs. Weight is with driver Minimum weight of 7500lbs

REGULATIONS

Ballast:

Ballast is permitted. Front hanging weights are allowed, no t to exceed 60 inches forward of the center of the front axle. This will be measured from center of front wheels to end of weight assembly

Ballast may be added in the bed of the truck.

Body:

The body must be the OEM truck body, including the full bed floor. The body must retain full sheet metal, after-market hoods are permitted. The hood must be closed and securely latched while the vehicle is hooked to the sled.

Brakes:

Four-wheel hydraulic brakes are mandatory.

Chassis:

The OEM chassis is mandatory. The engine must be in the OEM location for the body used. The vehicle must retain the full OEM chassis. Wheel tubs, back-half conversions, tube chassis, etc., are prohibited.

Cooling System:

Radiators must be in the stock location and be of at least stock size.

Credentials:

All drivers must have a valid state driver’s license.

Driveline:

An OEM transmission and transfer case are mandatory. They must have been an option on a one-ton

Or smaller pickup.

Driveshaft Loops:

All trucks must have at least six inch wide u-joint shields around the rear u-joint constructed of at least 1/4 inch steel or 3/8 inch aluminum that will safely contain the u-joint and the end of the rear shaft. All shields must be securely mounted to the vehicle. Any front shaft u-joint that is visible from the side of the truck must be shielded to contain the u-joint and the end of the shaft.

Driver Restraint System:

The OEM restraint system is mandatory and must be worn.

Engine:

The engine is limited to a stock-appearing, Engine and transmissions can be interchanged between Dodge, Ford and GM as long as they came in a 1 ton truck or less from the factory. Complete engine must have stock appearance except where otherwise noted in these rules.

aftermarket intake manifolds are allowed

Exhaust:

All vehicles must be equipped to direct exhaust upward. Two 3/8 inch diameter bolts must be placed through the exhaust pipe in a cross pattern within one inch of each other, within 12” of the turbo.

Fire Extinguisher System:

A fire extinguisher system is permitted. It must be securely mounted.

Firewall:

The complete OEM firewall is mandatory.

Floor:

The complete OEM floor pan is mandatory.

Fuel:

The fuel must be pump #1/#2 diesel, Soy/Biodiesel fuel. No propane or NO2 permitted or any other oxygen enhancers.

Fuel Injection Pump:

The fuel injection pump is limited to a stock-appearing, OEM engine model-specific pump only. The use of multiple high-pressure common-rail fuel pumps is legal. Powerstroke engines with a single factory turbo may utilize a second HPOP. Pumps from different years in the same engine model may be interchanged. P7100 pumps are allowed to run RSV (ag governors)

Fuel System:

Racing fuel cells are permitted

Hitch:

The hitch must be a "Reese"-style hitch; reinforcements are permitted. Trick hitches are prohibited. The hooking point must be the rear-most point on the vehicle and must be rearward of the stock location of the tailgate. The hitch must be horizontal to the ground and stationary in all directions. Bumpers may be notched or removed. The hitch's height from the ground may not exceed 26

inches. The hooking point must have a minimum 3.00 inch wide x 3 ¾ length inside diameter opening for the sled hook. The hooking point must be a minimum of 44” from the center of the rear axle to the center of the hooking point. The hooking point will be measured to the center of the clevis loop.

Rear End:

Non-OEM rear-end housings are prohibited. It must have been an option on a one-ton or smaller pick up. Rear axle bolts must be covered by a cap or shield.

Steering:

The vehicle must retain the full, original OEM steering gear. The vehicle must retain the original OEM power assistance, if it was so equipped. Additional stabilizers are permitted. Non-OEM power assist methods are prohibited.

Suspension, Front:

The upper mounting point for strut assemblies must be in the factory location. Adjustable caster/camber pillow ball mounts are permitted. The lower control arm may be strengthened provided factory-mounting points to chassis are maintained. The lower mounting point for the strut assembly may be modified for improved caster or camber. Strut tower braces, lower tie bars, sway bars, and limit straps are permitted. Traction bars and devices are permitted. Final decisions rest with the Scheid Diesel Technical Department.

Suspension, Rear:

An OEM-style suspension is mandatory. Lowering or raising the vehicle height with suspension modifications is permitted. Traction bars and devices are permitted; they must be bolt-on only; welds are permitted for attachment to frame or axle housing. All OEM suspension mounting points must be retained and used. Sway bars, limit straps, and camber kits are permitted. All rear suspensions must use at least one working shock absorber per wheel. Airbag spring assistance is permitted; airbag compressors must be disconnected. Blocked suspension is permitted.

Tires:

The tires must be DOT street tires. Cut tires are prohibited. 102” Max outside tire to outside Tire

Transfer Case:

Non-OEM transfer cases are prohibited. The transfer case must have been an option on a one-ton or smaller pick up truck.

Transmission, Automatic:

Non-OEM transmissions are prohibited. Aftermarket torque converters, valve bodies and internal components are permitted. Transmission brakes are prohibited. Any non-OEM floor-mounted automatic transmission shifter must be equipped with a spring-loaded positive reverse lockout device to prevent the shifter from accidentally being put into reverse gear. A functional neutral safety switch is mandatory. All transmission lines must be metallic or high-pressure-type hose. All vehicles using an automatic transmission must be equipped with a transmission shield meeting SFI Spec 4.1 and must be labeled accordingly. A blanket-type shield is permitted; it must be appropriately labeled as meeting SFI Spec 4.1 and it must extend from the rear of the block to the front of transmission main body the bell housing area is to be completely covered six inch overlap where it is fastened. All non-blanket-type shields must incorporate two (or one, per manufacturer’s instructions) 3/4 inch by 1/8 inch straps that bolt to the shield on each side and pass under the transmission pan unless the transmission pan is labeled as meeting SFI Spec 4.1. All vehicles using an automatic transmission must be equipped with a flex plate meeting SFI Spec 29.1 and be covered by a flex plate shield meeting SFI Spec 30.1.

Transmission, Manual:

Non-OEM transmissions are prohibited. Aftermarket internal components are permitted. A clutch meeting minimum SFI Spec 1.1 or 1.2 is mandatory on all vehicles. All manual transmissions must be clutch assisted. Sequential shifters are prohibited. All vehicles equipped with a manual transmission must

Have a flywheel shield labeled as meeting minimum SFI Spec 6.3 or greater. Applications for which an SFI Spec flywheel shield is not available may use a properly attached SFI 4.1 or 4.2 blanket that completely covers the bellhousing; it must be attached to the block and extend rearward to the transmission with a minimum six inch overlap where it is fastened.

Turbocharger:

The vehicle is limited to a 2.6 inducer bore single turbocharger. The compressor wheel must protrude into a 2.6” bore for 1/8”. The inlet will be measured using a 2.65 inch plug the plug must not be able to enter the inducer bore. A stock map width enhancement (MWE) groove is allowed. No MWE groove will be allowed that has a width greater than .200”. All provisions allowing air into the wheel other than via the bore and the MWE groove are prohibited. The vehicle driver will be responsible for making compressor wheel accessible for tech personal to measure bore and be able to inspect compressor wheel.

Water Injection:

Water injection is prohibited. All system components must be removed from the truck.

Ice Water Intercoolers

Are allowed

Wheelbase:

The vehicle must retain the original factory wheelbase and track width.

3.0 Class Rules

1. Maximum weight 8000lbs. Minimum weight of 7500lbs

2. Trucks must remain stock appearing.Must have full size steel or OEM type body. The bed of the truck must have a metal floor, if bed is gutted 200 lbs of movable weight must be placed rearward of the centerline of the rear axle,

3. Maximum engine size will be 460 cubic inch. Engines must come from factory in one ton or smaller Diesel pickup truck. Engine must remain in stock location as intended by manufacturer.

4. Front of engine block can be no farther forward than 17” of centerline of front axle.

5. Hook point must be no closer than 44” of centerline of rear axle, hitch height maximum of 26”, with a minimum of a 3.5” X 3.0” opening. Hitch point must be easily accessed. No “trick” type hitches permitted. Hitch must be stationary in all directions. Hitch must be frame mounted. Hitch must be mounted center line of rear axle or behind. Hitch must not exceed a maximum of 25 degree angle from pivot point to hook point.

6. One turbo with one pressure stage permitted. Maximum of 3.0” Opening on intake wheel. Map width enhancement is allowed not to exceed .250. Compressor wheel must protrude into three inch bore 1/8”, intake housing may not exceed three inches turbo mounting plates are permitted.

7. Exhaust must exit straight up, with (2) 3/8” bolts mounted in a cross pattern no more that 1” apart as close to the turbine wheel as possible, no more that 6” from turbine wheel

8. No cast iron clutches or flywheels permitted.

9. Fuel safety kill and/or air shutoff must be installed on the rear of truck. Kill switch will be securely mounted to the back of the vehicle and have a two (2) inch diameter ring to attach the sled.

10. No fuel lines or tanks permitted inside of truck cab unless securely mounted in marine box.

11. Computer chips and boxes permitted.

12. Fuel Systems: Largest fuel injection pump allowed will be a P-Pump with only one plunger per cylinder. (No Sigma pumps).

13. Must be D.O.T. approved tire. Maximum tire height 35” no studded tires or chains. No alteration to tires allowed. No bar or terra tires. Dual rear wheels are permitted.

14. Water injection permitted

15. Front weights must be no more than 60” from the center line of the front axle to forward most point and be securely fastened. No weights are allowed in cab of truck if in bed of truck they are to be securely fastened to bed of truck.

16. Fuel limited to diesel fuel and bio-diesel only. No alcohol, nitrous, propane or any oxygen enhancing agents allowed.

17. Drive train will consist of the following: Any front axle, any transfer case any rear axle. No planetaries permitted.

18. Axle shields are required. Shield to be .060” thickness steel or aluminum. Shield not to be mounted to axles ends or hub bolts. A hole may be cut in one to allow locking in of hubs.

19. S.F.I. Bell housing Blankets and /or S.F.I Blow proof Bell housing required.

20. All U-joints must be shielded 360 degrees with 3/8” thick aluminum or 5/16” thick steel. Shield will be 6 inches long minimum and centered on U-joint. Inside diameter of shield will be no more than 2 inches larger than U-joint.

21. All intermediate shafts between the transmission and transfer case will be totally enclosed in 3/8” aluminum or 5/16” steel, ¼” of shaft may be visible.

22. Suspension modifications are permitted. Removable suspension blocks are permitted.

23. Fire Extinguishers, helmets Snell 85 or better, SFI fire suits, shoes and seatbelts required.

Pull track managers will have final say if a truck is in question

Safety will not be sacrificed by an unsafe vehicle or driver

We will work to get complete info soon on times , hook fees and all other info.

I can tell you this that Workstock and 2.6 will pull Friday night and the top 8 trucks will be invited back on Saturday to pull in the main show.

dirttymaxx

New member

were looking for the work stock rules,but we mite have our new turbo by them so we mite jump up to 2.6

NHRDA

New member

An update on the Fass Diesel Nationals! The sled pulling track is being constructed as we speak, and unlike other years, they are building it to be a permanent track in the same location as it has been in past years!!! This should make for a great track both this year and at future years events!!!

John Robinson

New member

40k is a big purse.:rockwoot:

Can you post a payout breakdown.

Thanks!

What he said...

What he said...

Ill ask randy and get back to you guys as soon as i hear back from him.

NHRDA

New member

40k is a big purse.:rockwoot:

Can you post a payout breakdown.

Thanks!

The numbers in Parenthesis are the number of racers needed to meet that percentage of the payout.

JerrodGlover

Pulling God

So am I reading wrong or your only paying out to the top 2 in the Dragracing classes? What is the breakdown of the payout in sled pulling?