Hurley

BLAKLUNG

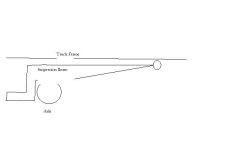

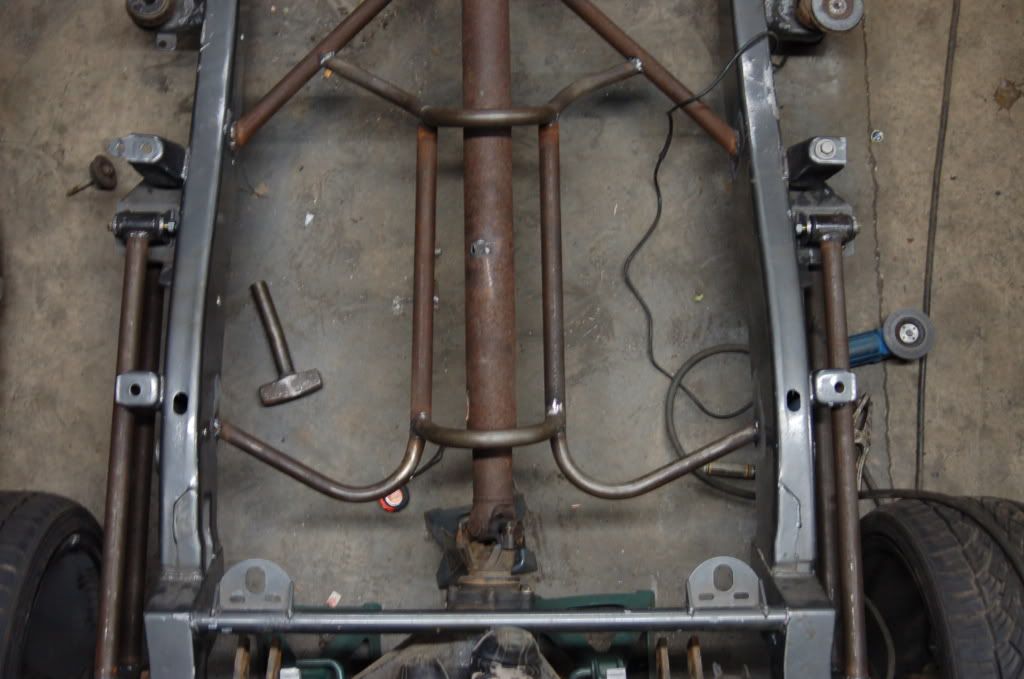

Got er down to 166%.... Got some measuring to do on the truck and we'll get some more accurate numbers. Tire size is pretty much for certain. Axle end heights for the links are pretty much certain as well. Just gotta figure frame end heights.

wait, are you trying to make a double-triangulated 4-link or a parallel 'ladder bar' suspension? I thought you were going for the ladder bar setup? (which will require you to make all 4 bars parallel from the top view) Either way, you might want to drop the frame-side mounting point to decrease antisquat even more; and to be more realistic you will also need to spread the centerline distance between the axle mounting points... or do you intend to have the mounting points be actually ahead of the axle centerline?

Last edited: