BC847

New member

I remember that thread: Crank lightening - Competition Diesel.Com - Bringing The BEST Together

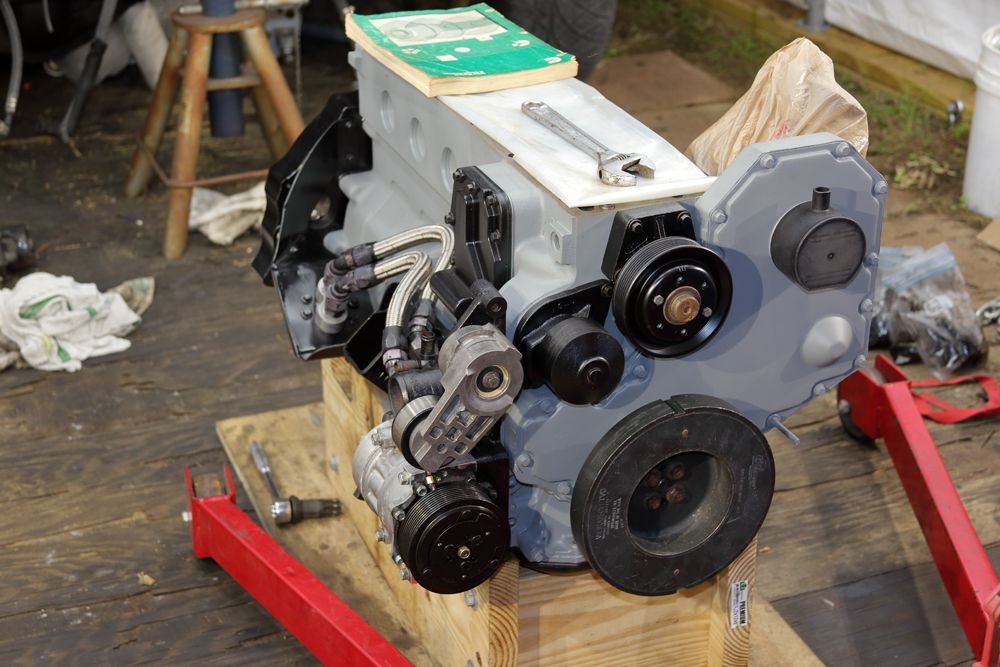

Lots of the build pics here: http://www.devilscastle.net/

Lots of the build pics here: http://www.devilscastle.net/

Last edited:

.jpg?width=1920&height=1080&fit=bounds)