Been busy. I Mounted Snow plow electronics, new radiator etc... and was ready to try and hook up to new plow. Well started truck up and clutch pedal won't allow it to go into gear. I can only go into gear when transfer case is in nuetral. The Slave and clutch master must have air in them.

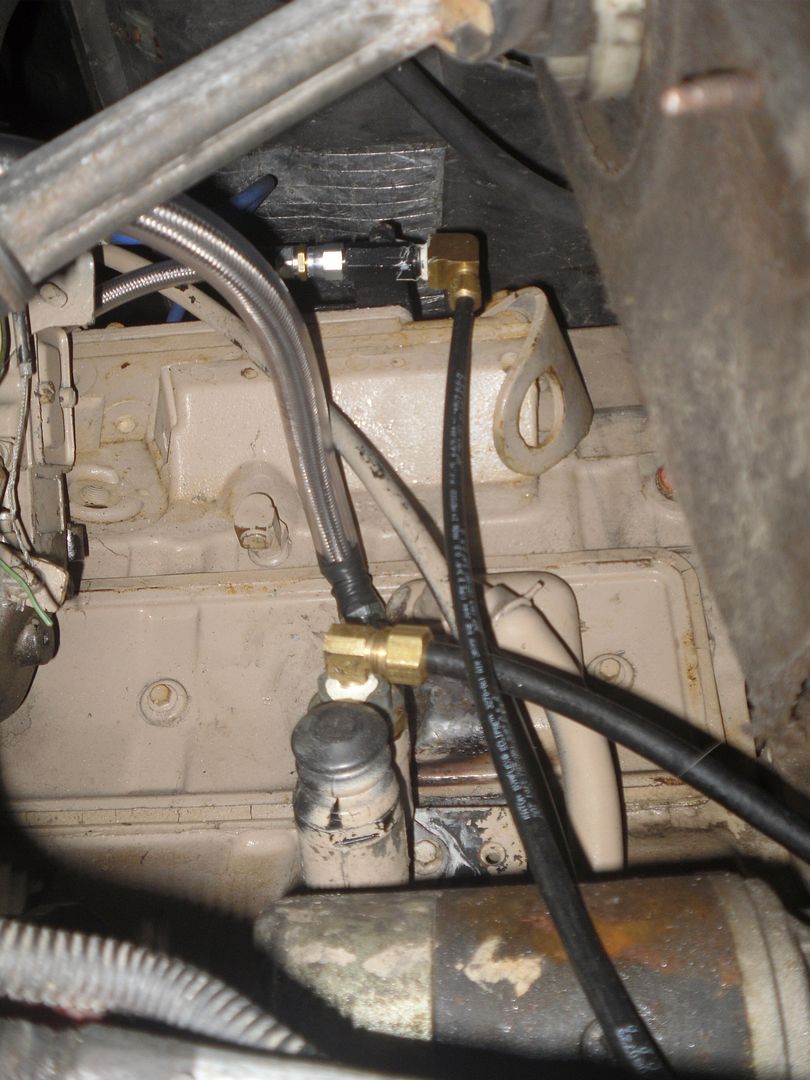

I tried pumping pedal , tried pumping slave from under the track, tried pumping both at same time with helper. Tried a mityvac into the resevior hole with lots of vacuum, tried mityvac suction while pumping slave, tried mity vac and pedal pumping.. all with no luck. VERY Frustrated. Spent Hrs. like 5 hrs in the dark trying to get these Hydrualics to work.

I have been attempting to keep the slave level or with the line higher then the cyl... any not sure how to proceed.

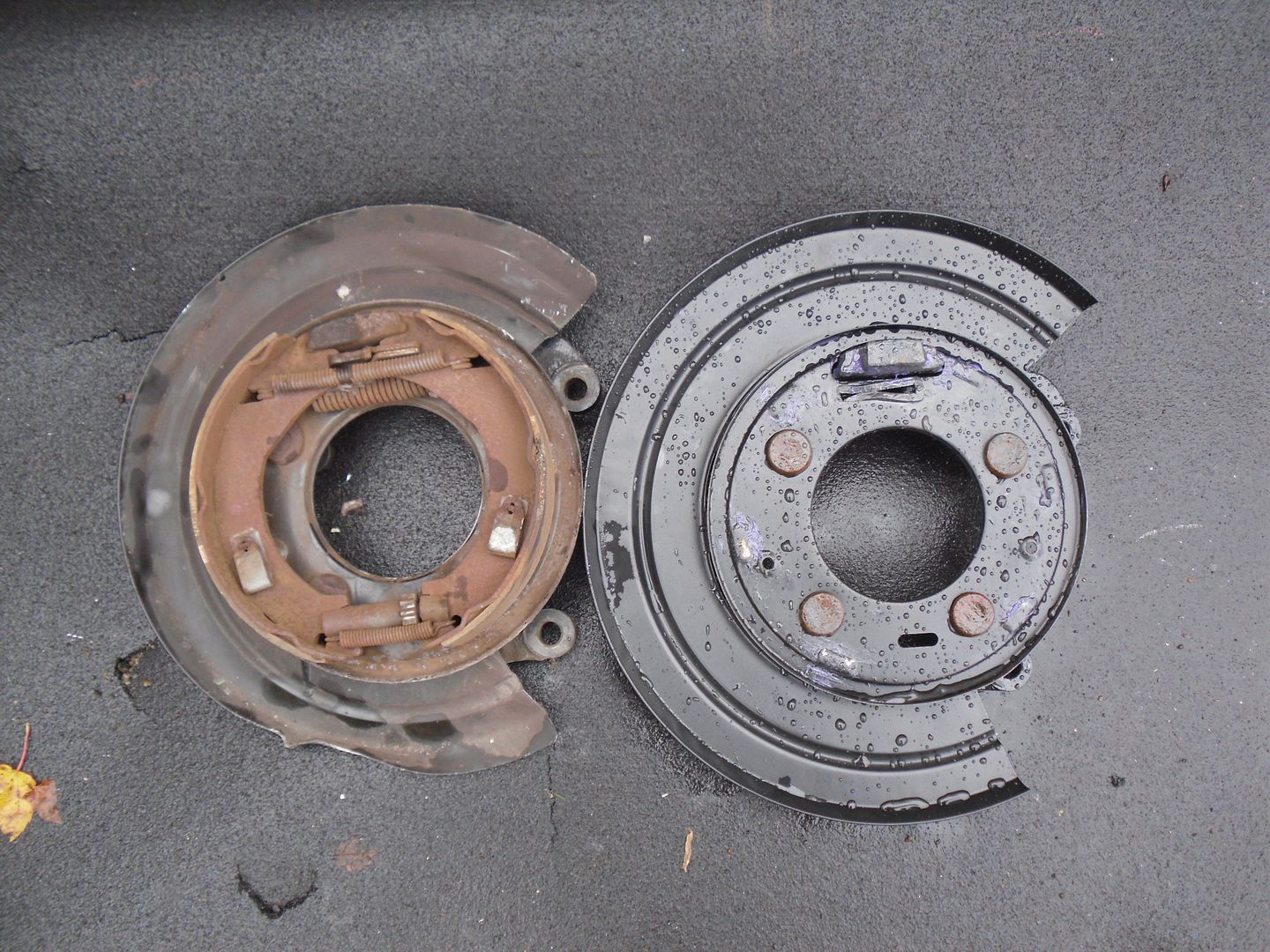

The trans side is a 2 stud flange slave to fit the G56 / nv4500 style trans. The Master is a 2 hole master that fits over the ford pedal box studs. I'm not sure is the previous owner used a dodge setup in the ford, or added a dodge slave to a ford master? ....the ford slave looks like a twist connection to trans from service manual, whereas the dodge is flange style. I think the dodge master has 2 studs in it to bolt into the fire wall, and the ford master slides over two protruding studs from firewall in the engine compartment ?

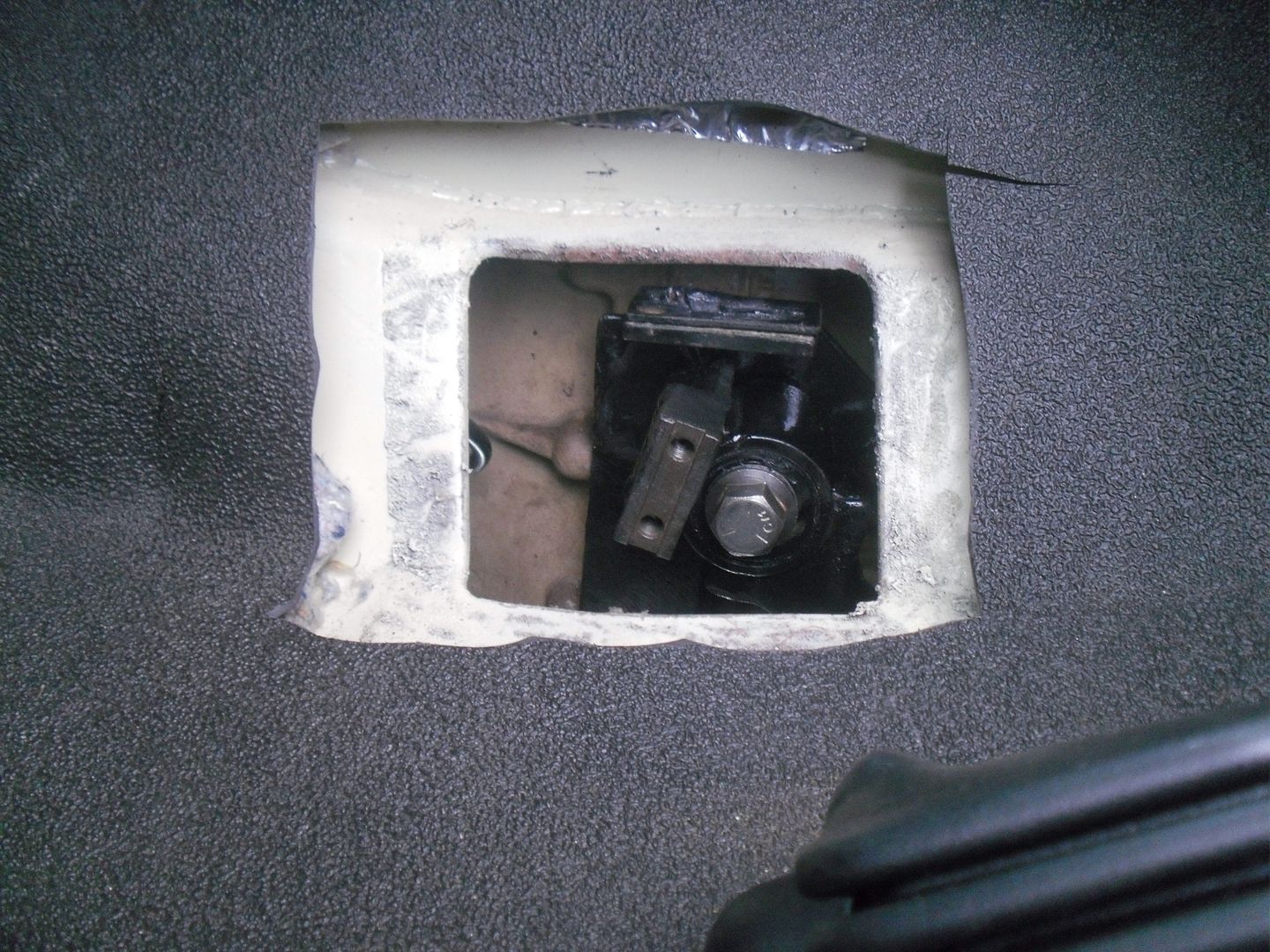

Read a old post from Roachie some where that says take the dodge master and knock the studs out of the metal firewall flange it has, then you ream them out a little, and it will fit the ford pedal box studs that stick out of the firewall. My Ford clutch pedal and push rod are custom modified pieces. the metal rod was welded longer and the ford plastic rod click was discarded. i drilled the pedal pine out to use a cotter pin retainer etc. the pedal used to break the ford clip constantly and drop the pedal to the floor. That sucked alot especially in traffic. Any how i changed that years ago and before i swapped the trans.

Any tips on how to bleed the sytsem with a mity vac?

I have a new HD slave here with the metal master cyl flange it has 2 studs sticking out of it. I assume its a dodge style? It has a funky adjustable master push rod with a plastic clutch switch attached to it?? I'm about ready to pound those studs off and try to swap this one into the truck. I have no clutch switch in this truck and hope it all matches up.?

Help, Tips appreciated...

Thanks,

Deo