You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

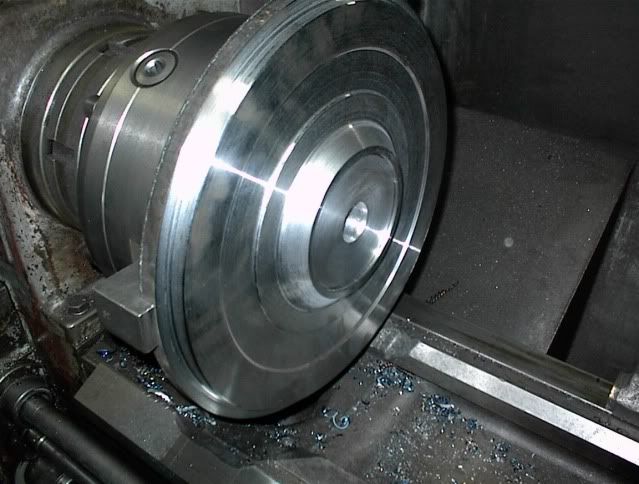

Homemade flywheel

- Thread starter renopker

- Start date

SuperSonic

El Vato

- Joined

- May 31, 2006

- Messages

- 2,036

Do you plan on setting a replaceable wear donut into the face?

renopker

New member

- Joined

- Dec 22, 2007

- Messages

- 514

Do you plan on setting a replaceable wear donut into the face?

Ya 1/4 wear plate. As for the disc, buy the parts or buy the disc ready done or modify one, same with the pressure plate.

renopker

New member

- Joined

- Dec 22, 2007

- Messages

- 514

Looks like you are not just building it for yourself. Maybe you need to step up and pay to be a sponser as you are obviously advertising right now.

Peter

Not advertising I sell nothing I build or have built on here.I will probably post the dfx file for this flywheel when its finished.Then anybody can build one.build the things you can and buy what you cant.:Cheer:

diesel_importer

Active member

- Joined

- Oct 21, 2007

- Messages

- 4,501

this guy just doesn't quit.

Red_Rattler

High Tech Redneck

- Joined

- Nov 5, 2007

- Messages

- 2,090

Keep them coming, I love watchin threads like this

zstroken

For $$$ your name here

- Joined

- Sep 27, 2006

- Messages

- 23,151

Copying cam profiles and now Peter's flywheels? Wow....

fat fingered using Tapatalk

Sad part is, u don't think he is the only one copying things? He has said he isn't reselling them on the site. He just has the gumption to show he is doing it.

renopker

New member

- Joined

- Dec 22, 2007

- Messages

- 514

The nerve of this guy building his own parts and then posting pics that we might see some hard parts in progress.Ya he just doesn't quit, he needs to step up and buy these parts like everyone else.Well guys after 35 years of building these parts and yes clutches too I'm building parts for my truck for the fun of it.Hard to believe that parts may look alike yet still be different. I wonder who's gonna complain about what my injectors or who's they look like.Sad part is you guys would lean more asking questions that would help you in the future. And no SB flywheel was used in the making of mine.

bbbxcursion

traitor

- Joined

- Apr 20, 2008

- Messages

- 817

Not this guy again

Let him roll...he is not selling them....no harm no foul. He might add to the development of any of the products he machines himself. I do the same thing when I can.

Can anyone think how to machine down the diameter a 1/4inch on my 34 mm sway bar?

Just between the mounts. That is a great thought!

Can anyone think how to machine down the diameter a 1/4inch on my 34 mm sway bar?

Just between the mounts. That is a great thought!