Well I can't say for sure what the timing is in degrees that we ran (thank you arbitrary Smarty), nor the duration (again thank you arbitrary Smarty).

We ran the standard injection events.

We did tune on a dyno to peak timing numbers (until they fell off and then went back) and peak duration numbers (until it fell off and then we went back).

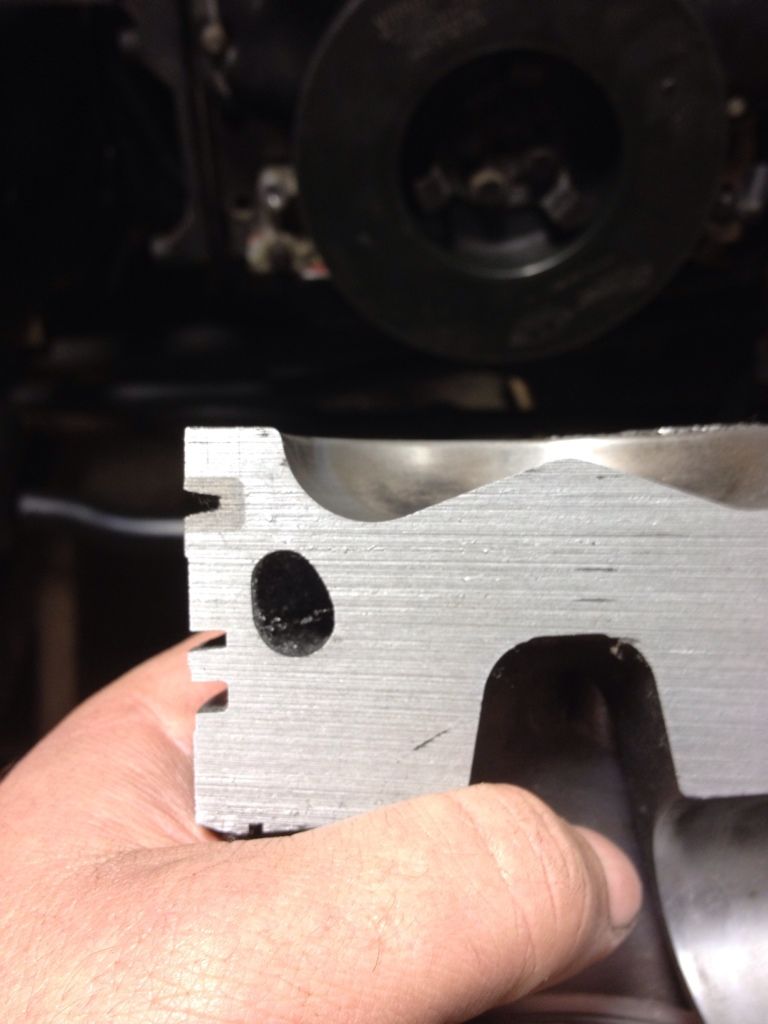

Here is what the piston looked like when we pulled it out, sorry for the cell phone pic, but the piston its self is not what we are looking at just the spray pattern. Obviously in the bowl, at 1200whp+ on fuel and 1500whp+ on the juice.

To get every last drop of fuel needed to make a 149.72mph pass out of a nearly 7000lbs truck, we were using enough duration that we were getting such late fuel it did this to our expansion tube AFTER the JGS external wastegate:

It also tuliped all of the exhaust valves.

We obviously have a new plan for this year, as while that made power, it was hard on parts, and the longevity of the power was short.

The long of the short is:

If you are spraying out of the bowl with the 143 degree nozzles, you are doing it wrong.