jeff115

New member

- Joined

- Apr 20, 2009

- Messages

- 622

not sure if this would go in engine tech or turbo?

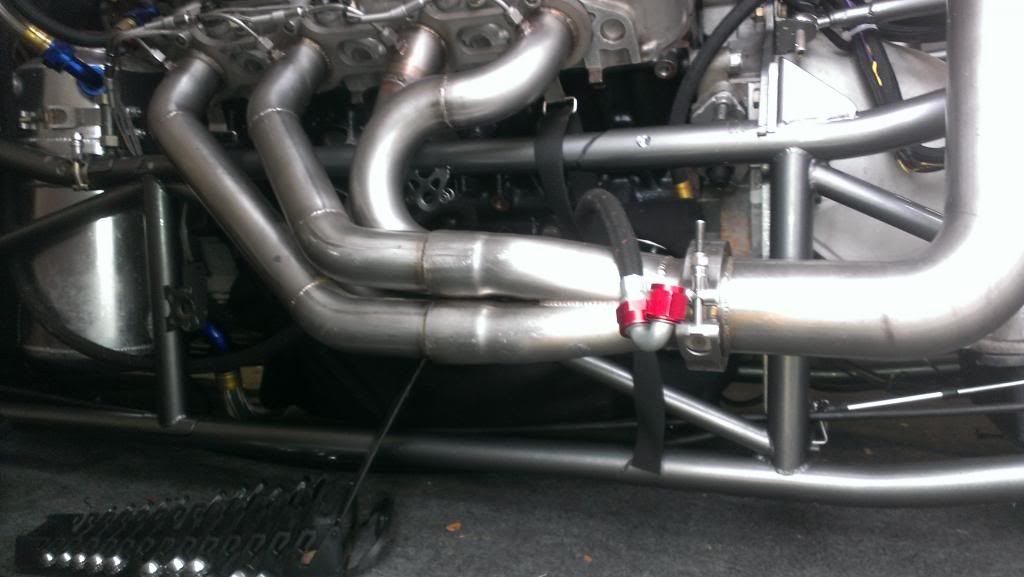

I have a few sets of flanges, and am getting ready to make a few exhaust manifolds. have you guys seen any 180 degree headers? pairing 1,6-2,5-3,4 into an open exhaust housing? helps with low/mid on a gasser. Would it help spool a turbo better? I'll bet it would look cool any way.

I have a few sets of flanges, and am getting ready to make a few exhaust manifolds. have you guys seen any 180 degree headers? pairing 1,6-2,5-3,4 into an open exhaust housing? helps with low/mid on a gasser. Would it help spool a turbo better? I'll bet it would look cool any way.