I've been looking at these after a few friends experince with their 5.0 mustang (coycote motors) where they would pop due to a lean condition in the ECM programming and that rear cylinder being the hottest. I saw the fleece kit and while it's very nice, for what I'm doing it's out of price range.

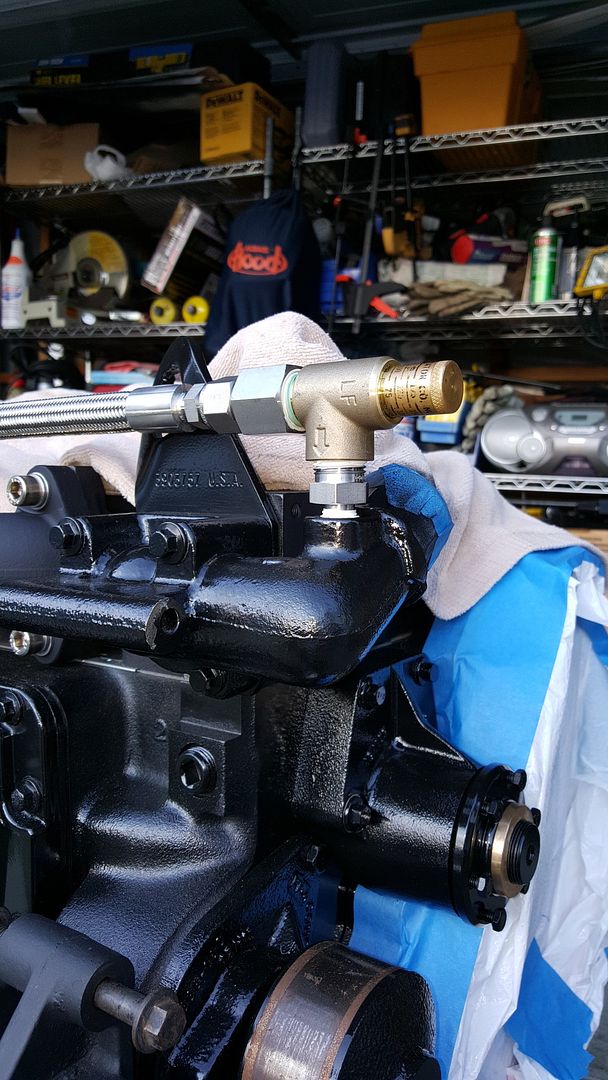

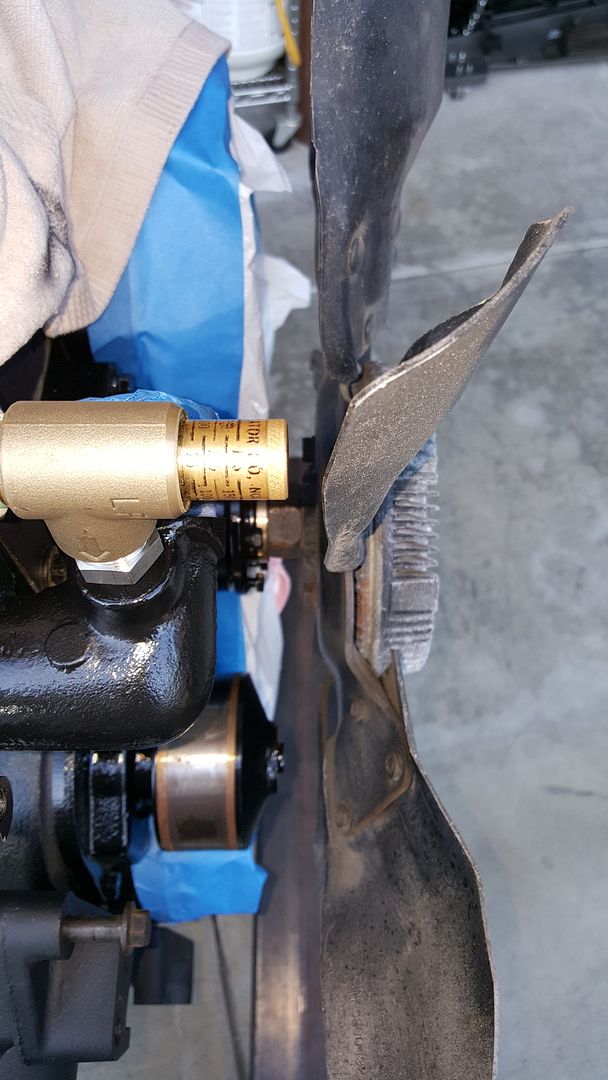

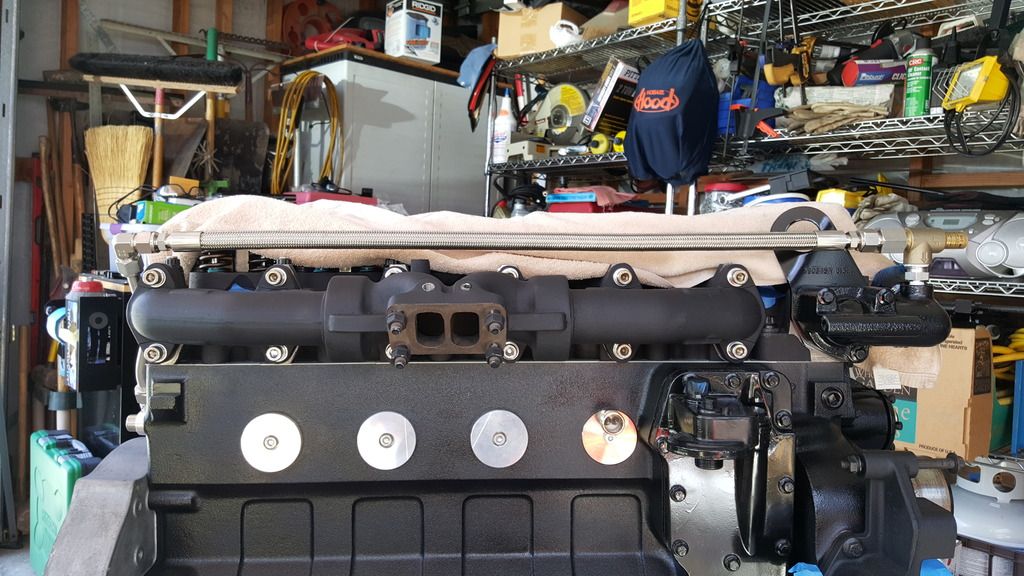

I did happen to find this guy

Dodge 5.9L Cummins Cylinder #6 Cooling Kit Improves Coolant Flow

I assume it can be installs to the port can face the driver or passenger side.

Just run a line from the rear of the block to where the metal heater hose bolts to the thermostate housing.

any other ideas?

I did happen to find this guy

Dodge 5.9L Cummins Cylinder #6 Cooling Kit Improves Coolant Flow

I assume it can be installs to the port can face the driver or passenger side.

Just run a line from the rear of the block to where the metal heater hose bolts to the thermostate housing.

any other ideas?