Bponci

rookie

- Joined

- Sep 15, 2006

- Messages

- 2,160

Wow. Just shows bigger isn't always better

Sent from my iPhone using Tapatalk

Thats what i have been telling my wife for years!.....LMFAO!!!:hehe:

Wow. Just shows bigger isn't always better

Sent from my iPhone using Tapatalk

Wow. Just shows bigger isn't always better

Sent from my iPhone using Tapatalk

This isn't www/competitionsupra/com, so I don't see how your comment is relevant to the conversation at hand.

Half the displacement.and double the rpm.

Little 6, do you mind sharing what a/r is on the 4202? Is this a 5.9 or 6.7? Very similar to what I have in mind. Actually interested in both turbine housings if you don't mind....

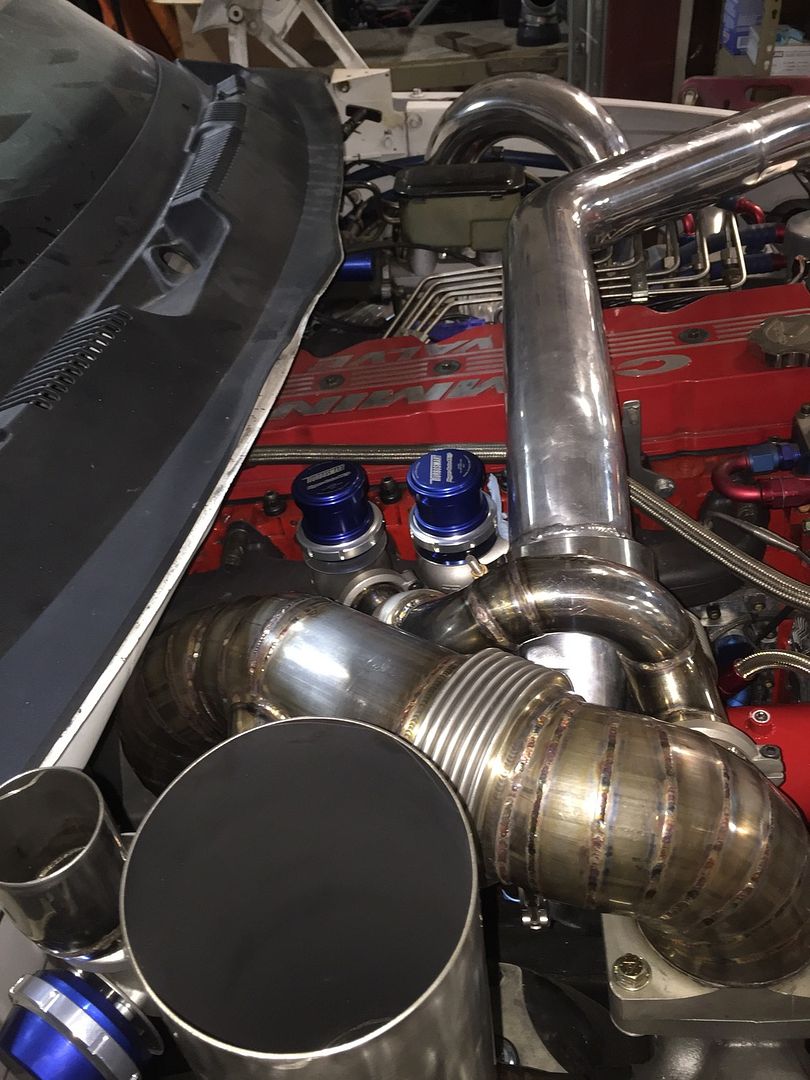

I'm running a GTX4202 and a GTX5533-94 with 2 45mm gates on the manifold and one more around the primary. My drive:boost ratio is always 1:1 up to about 100psi drive then the drive creeps up a little. The highest I've ever seen it is just under 1.2:1.

Sorry...was this of the BW 80/96/1.32, or the BW 88/110/.85? Again...single application, correct?

There's no revelation there, the 96mm/1.32 outflows the 110mm/.85.

What are your gates set at for opening pressures?

Are you tying the two gates off the manifold into the hot pipe, or to the atmosphere? (I'm guessing into the hot pipe....one gate though...or both?)

What is the gate in the hot pipe set at for opening pressure on the primary?