adamsmarshall

Drilling Crooked Holes

- Joined

- Oct 12, 2008

- Messages

- 1,915

If you want to keep it simple, have rods made 194mm long. This will keep piston protrusion the same as stock 6.7 specs. If you wish to raise compression, make the rods longer than 194mm, and machine the top of the piston down the same amount, reducing the cc of the bowl the correct amount to get your desired compression ratio.

As much as that makes sense, the 194 mm almost sounds too short for stock protrusion. Grant you that's something that I'd just have to measure for, but the reason I say that is the stock rod lengths on the billets I just sold showed 7.559" (191.9986 mm)

I know it doesn't take much difference in length but only 2 mm seems like it wouldn't be enough. But like I said I'd have to measure for it so until then I'll take your word for it!

The original 205-207 mm length mentioned in the first post was something I saw you mention in another thread so that's why it was initially brought up.

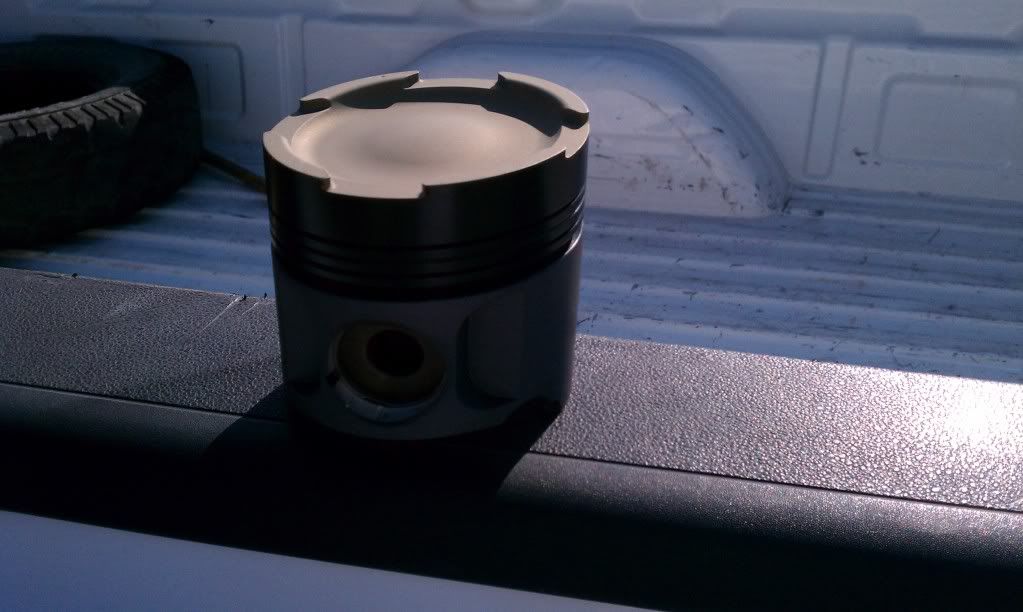

As for compression the plan is to try to end up with 16.5-16.7:1. Mainly due to having to cut valve reliefs for the cam and rather than valve reliefs the plan is to just deck the piston to prevent potential hot spots on the edges of the reliefs.