You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disassembly for rebuild has started.

- Thread starter jimbo486

- Start date

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

It's running great so far. Haven't driven it too much since I'm still waiting to hook to something heavy or shaped like a barn to drag around and seat the rings but drove to and from work yesterday.

After driving home from work last night, I found it'll still make at least 45psi. It seemed like I was only into the throttle about 75%. Cruising at about 75mph, ~2100RPM, EGTs are down. To my best recollection, they were up around 750degs. prior. Yesterday I was seeing 625-650degs. That's always good. I didn't notice what they were when I goosed it but I have no doubt they'll be a little lower overall.

The exhaust note is noticeably deeper with the cam, too. It was fairly tolerable before the rebuild with the stock cam but my ears were ringing for a bit after that drive home LOL. Certainly need to get an FTE resonator on this thing now.

After driving home from work last night, I found it'll still make at least 45psi. It seemed like I was only into the throttle about 75%. Cruising at about 75mph, ~2100RPM, EGTs are down. To my best recollection, they were up around 750degs. prior. Yesterday I was seeing 625-650degs. That's always good. I didn't notice what they were when I goosed it but I have no doubt they'll be a little lower overall.

The exhaust note is noticeably deeper with the cam, too. It was fairly tolerable before the rebuild with the stock cam but my ears were ringing for a bit after that drive home LOL. Certainly need to get an FTE resonator on this thing now.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

I guess I've missed this thread this whole time. I've always liked this truck. Glad it's coming around!

Thanks!! That means a lot to me hearing it from a veteran Comp D guy.

BRE

Active member

- Joined

- May 19, 2010

- Messages

- 12,732

Thanks!! That means a lot to me hearing it from a veteran Comp D guy.

Whoa whoa whoa... I'm no veteran. Just some punk kid.

BRE

Active member

- Joined

- May 19, 2010

- Messages

- 12,732

Haha I made an assumption based on your post count.

I post a lot of bs... Pointless bs

6.7outdoorsman

New member

- Joined

- Dec 30, 2011

- Messages

- 33

Finished up filling all the existing cab light mounting holes. Ready for the 3rd gen lights to go on.

Back to some engine work. I painted the timing cover which I think is the last of the engine parts.

Been a long time since I've seen the engine sitting in the frame. But had to take it right back out after seeing the lack of clearance for the coolant bypass.

So I tried my best at body work with an 8lbs. sledgehammer. LOL Thankfully, nobody will see much of this.

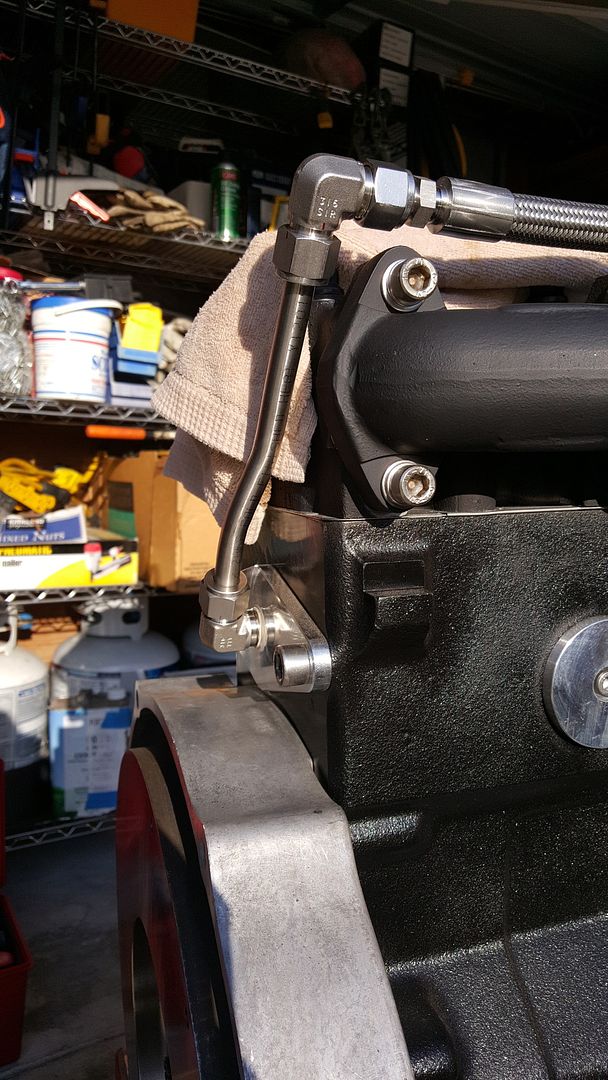

So I had to change things up a bit. Earlier today, I picked up the stainless hose I ordered.

I ground off some of the shoulder on the thermostat housing neck.

Made a new length of tubing with a slight 'S' bend in it.

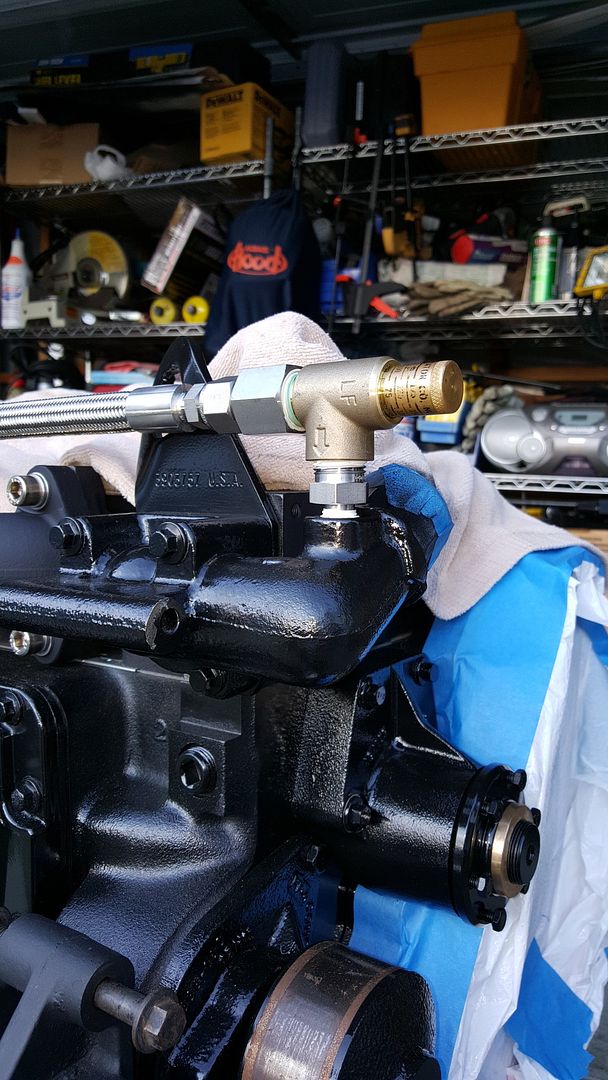

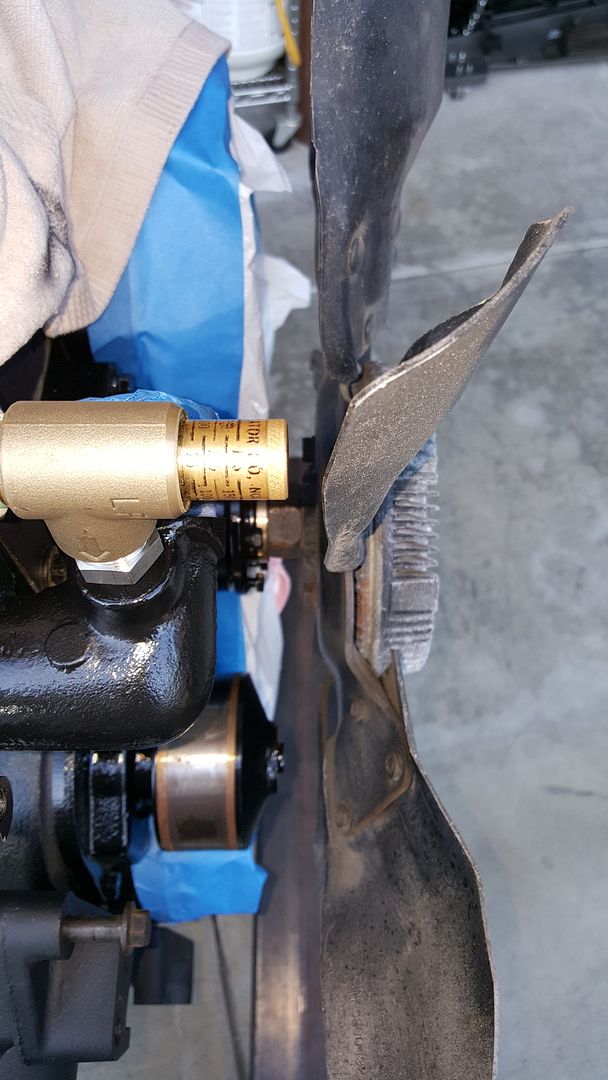

Used a 1/4" x 1/2" stainless nipple and put the PRV at the thermostat housing.

I'm diggin' it!! :rockwoot:

Luckily, a solid 3/8" of clearance at least for the fan blades.

Do you have any part numbers for the swagelock fittings you used?

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

I can get them for you.

To update, the leak revealed itself again and a replacement gasket didn't fix anything. Long story short, a new head is in the works. The o-rings were cut wrong. A lot of back and forth with Eric at Hungry Diesel. We've found that somewhere along the way, the gasket manufacturer changed the outer diameter of the fire rings. Therefore, the o-rings landed on the very outer edge of them and prevented crushing which kept the head from seating into the rest of the gasket. Thus, the leak I initially found.

After all this, I'm somewhat hesitant about o-rings. I'm debating whether or not to have o-rings put in the new head. Some have speculated that with the CA625 studs, I probably don't. But I've taken every other precaution with this build. I'd like to think that if the o-ring grooves are cut correctly, with dimensions that match the fire rings, there shouldn't be a single issue. By match, I mean, o-rings land in the center of the fire rings and allow proper and plenty of crush.

Thoughts?

To update, the leak revealed itself again and a replacement gasket didn't fix anything. Long story short, a new head is in the works. The o-rings were cut wrong. A lot of back and forth with Eric at Hungry Diesel. We've found that somewhere along the way, the gasket manufacturer changed the outer diameter of the fire rings. Therefore, the o-rings landed on the very outer edge of them and prevented crushing which kept the head from seating into the rest of the gasket. Thus, the leak I initially found.

After all this, I'm somewhat hesitant about o-rings. I'm debating whether or not to have o-rings put in the new head. Some have speculated that with the CA625 studs, I probably don't. But I've taken every other precaution with this build. I'd like to think that if the o-ring grooves are cut correctly, with dimensions that match the fire rings, there shouldn't be a single issue. By match, I mean, o-rings land in the center of the fire rings and allow proper and plenty of crush.

Thoughts?

Last edited:

I don't see the benefits out way the issues in your build. With your 625 studs you can crush the factory ring tighter than most. Unless you are running extreme timing or intend to play with nitrous I would not bother. Most of the p pump guys don't start o ring talk until 600+ hp based on your ve choice, I don't see it. I love my ve as a daily driver too.

96 3500 5x018 7mm dvs 62fmw

96 3500 5x018 7mm dvs 62fmw

9724VF350

Tractor Guy

- Joined

- Mar 2, 2010

- Messages

- 2,784

Thoughts?

Quit fukking around and put a OEM head gasket like I told you a long time ago.

fatty

VE

- Joined

- Mar 23, 2009

- Messages

- 959

Just because your shop screwed up and did the orings wrong is no reason to shy away from it. Find a shop that knows what they're doing and have them cut orings so it will work. I had my head cut for o rings 6 years ago and it has yet to give me trouble.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

Quit fukking around and put a OEM head gasket like I told you a long time ago.

Listen bud, I did. Twice. Victor Reinz makes Cummins gaskets. There were some changes made years ago and we found that the outer diameter of the fire rings had been reduced. Therefore, the o-ring grooves were cut too wide. The machinist wasn't aware of the change and didn't adjust his jig accordingly. We all had no idea until we started taking dimensions. Apparently he's been lucky with other heads he's cut grooves in. Unfortunately, it's my luck that I got the one that didn't work.

I'll post pictures of the gasket I pulled out showing where the o-rings landed.

Last edited:

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

Definitely never gonna play with nitrous. No intentions to or even any curiosity.I don't see the benefits out way the issues in your build. With your 625 studs you can crush the factory ring tighter than most. Unless you are running extreme timing or intend to play with nitrous I would not bother. Most of the p pump guys don't start o ring talk until 600+ hp based on your ve choice, I don't see it. I love my ve as a daily driver too.

96 3500 5x018 7mm dvs 62fmw

As for timing, I know this pump has a big sweep on the dynamic advance but I've never been able to determine exactly what it peaks at. Regardless, I don't think it's an extreme advance.

Since I took every other precaution, I figured o-rings can't hurt so long as they land on the fire rings correctly.

I think the ideal way to do it is to get a new gasket take whatever dimensions are necessary to ensure that the o-rings land dead center on the fire rings.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

Luckily it wasn't a shop I chose. This was all coordinated through Eric at Hungry Diesel so it's his machinist or local engine builder, I forget. But Eric is standing by his promise to me and replacing the head.Just because your shop screwed up and did the orings wrong is no reason to shy away from it. Find a shop that knows what they're doing and have them cut orings so it will work. I had my head cut for o rings 6 years ago and it has yet to give me trouble.

I am glad to hear again that Eric is a stand up guy to deal with. Usually you read more bad than good on these forums. I still hate that you had trouble, but at least you weren't left standing out alone in the cold.

96 3500 5x018 7mm dvs 62fmw

96 3500 5x018 7mm dvs 62fmw

9724VF350

Tractor Guy

- Joined

- Mar 2, 2010

- Messages

- 2,784

Listen bud, I did. Twice. Victor Reinz makes Cummins gaskets. There were some changes made years ago and we found that the outer diameter of the fire rings had been reduced. Therefore, the o-ring grooves were cut too wide. The machinist wasn't aware of the change and didn't adjust his jig accordingly. We all had no idea until we started taking dimensions. Apparently he's been lucky with other heads he's cut grooves in. Unfortunately, it's my luck that I got the one that didn't work.

I'll post pictures of the gasket I pulled out showing where the o-rings landed.

In 5+ years my best customer hasn't had to adjust his BHJ tool for fire ring diameter on OEM gaskets. I'm both a Cummins and Mahle/Clevite/Victor dealer. If you didn't take it out of the OEM Cummins package, it's not a OEM gasket. There are differencess, I don't care who makes them. We learned all this crap the hard way years ago.

Mahle supposedly also makes Cummins pistons, yet they will score quicker than a OEM piston will.

Either you're you're using Victor gaskets and calling them OEM, or your machine shop fukked up and is passing the blame to the gasket.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

In 5+ years my best customer hasn't had to adjust his BHJ tool for fire ring diameter on OEM gaskets. I'm both a Cummins and Mahle/Clevite/Victor dealer. If you didn't take it out of the OEM Cummins package, it's not a OEM gasket. There are differencess, I don't care who makes them. We learned all this crap the hard way years ago.

Mahle supposedly also makes Cummins pistons, yet they will score quicker than a OEM piston will.

Either you're you're using Victor gaskets and calling them OEM, or your machine shop fukked up and is passing the blame to the gasket.

I'm calling the Victor gasket OEM because they're known to make the gaskets for Cummins. If Cummins isn't making their own but you get a Victor gasket from Cummins, what else are supposed to assume?

The machinist didn't deny any wrong doing. After taking a ton of dimensions we found the difference and he accepted blame. Yes, the first gasket was a Victor which was supplied with the Mahle rebuild kit. The second one I tried was straight from Cummins. I asked while at the parts counter if they are able to see who the mfg is. In this case, it didn't list anything. But it leaked just the same as the Victor did.

Eric had a chance to measure new gaskets straught from Cummins and found dimensions to be very close to those of the Victor.