EverydayDiesel

I drink diesel

- Joined

- Feb 12, 2016

- Messages

- 196

Hello,

I had a head gasket go south and I decided to upgrade the rods while the truck was down. Carrillo rods with carr bolts just showed up in the mail and I plan on getting new bearings, hamilton 188/220 cam, new oil pump, rings, coated pistons and a girdle at the minimum.

I have no experience working on rotating assemblies so I feel I am at least entitled to some dumb questions. So for those of you that have experience doing this please chime in.

The truck has 121,000 miles on it.

Should I

Plan A

1. Replace the rods only

2. Have the head flattened

3. Have head o-ringed

Plan B

1. Dissemble the block and have it checked

2. Top of block flattened

3. Bottom of head flattened

4. Have head o-ringed

Plan C

1. I am open to suggestions

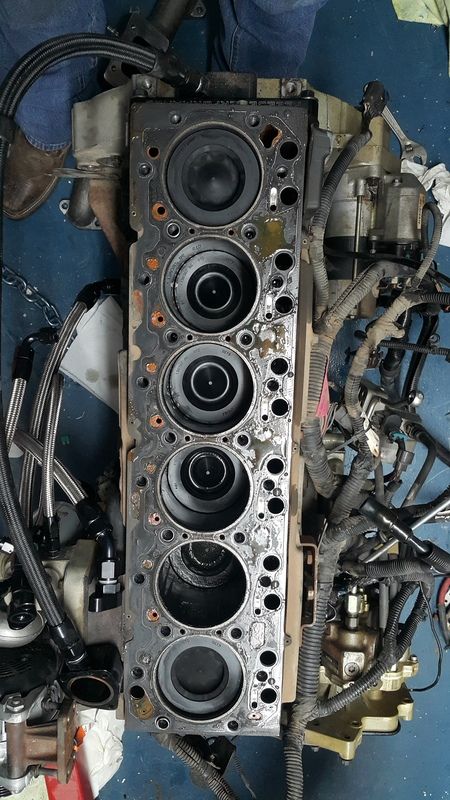

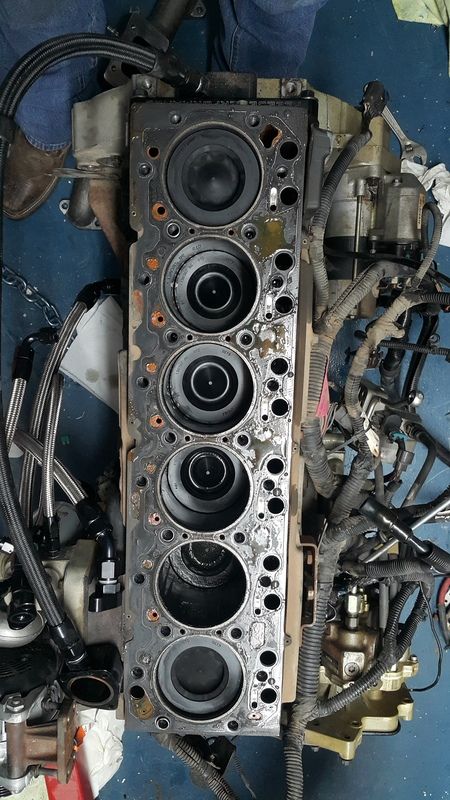

Here is the block as it sits

I am open to any advice/experience you can give me.

Are plasti-gages ok to use for this build?

Should I buy a fowler cylinder bore gauge?

Build goals.

1. Daily Driver

2. 8-900 RELIABLE horse power

3. 4000 rpm, its a daily driver street truck so I have no need to spin the crap out of the motor

Thanks in advance on any advice you can give me.

I had a head gasket go south and I decided to upgrade the rods while the truck was down. Carrillo rods with carr bolts just showed up in the mail and I plan on getting new bearings, hamilton 188/220 cam, new oil pump, rings, coated pistons and a girdle at the minimum.

I have no experience working on rotating assemblies so I feel I am at least entitled to some dumb questions. So for those of you that have experience doing this please chime in.

The truck has 121,000 miles on it.

Should I

Plan A

1. Replace the rods only

2. Have the head flattened

3. Have head o-ringed

Plan B

1. Dissemble the block and have it checked

2. Top of block flattened

3. Bottom of head flattened

4. Have head o-ringed

Plan C

1. I am open to suggestions

Here is the block as it sits

I am open to any advice/experience you can give me.

Are plasti-gages ok to use for this build?

Should I buy a fowler cylinder bore gauge?

Build goals.

1. Daily Driver

2. 8-900 RELIABLE horse power

3. 4000 rpm, its a daily driver street truck so I have no need to spin the crap out of the motor

Thanks in advance on any advice you can give me.