Cummin_un_glued

New member

- Joined

- Sep 17, 2007

- Messages

- 785

Drawing up prints for the machine shop. Any input?

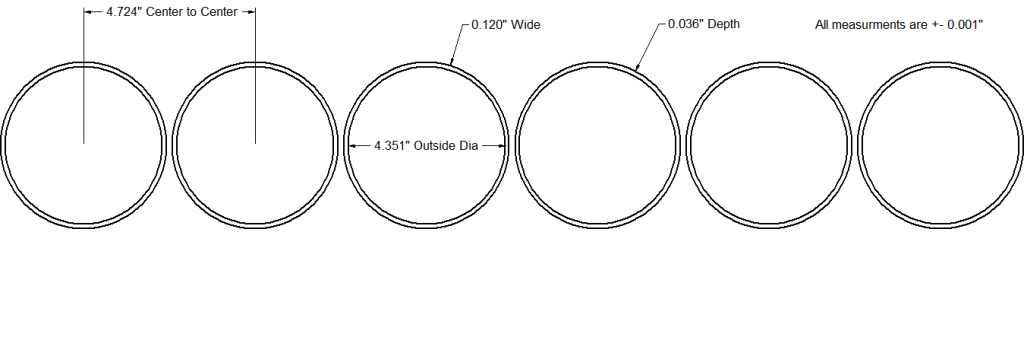

Fire Rings

[ame="http://s1229.photobucket.com/user/torquedieselllc/media/Firerings_zps6e0650e0.png.html"]Fire Rings Photo by torquedieselllc | Photobucket[/ame]

KDEL injector bore

[ame="http://s1229.photobucket.com/user/torquedieselllc/media/InjectorBore_zpsb558170f.png.html"]KDEL Photo by torquedieselllc | Photobucket[/ame]

anybody see any flaws?

Fire Rings

[ame="http://s1229.photobucket.com/user/torquedieselllc/media/Firerings_zps6e0650e0.png.html"]Fire Rings Photo by torquedieselllc | Photobucket[/ame]

KDEL injector bore

[ame="http://s1229.photobucket.com/user/torquedieselllc/media/InjectorBore_zpsb558170f.png.html"]KDEL Photo by torquedieselllc | Photobucket[/ame]

anybody see any flaws?