EPA Violator

CR Wrencher

- Joined

- Mar 8, 2008

- Messages

- 560

Been doin' some figurin' It turns out that with 03-04 injectors, 143 deg spray pattern you actually spray outside the bowl at about 12 deg or so before TDC. I am sure Smarty and all the others advance the timing more than this even with the mild timing settings. This kinda dispells the hypothesis that timing advance is melting these things, because if that was true we all would have melted pistons.

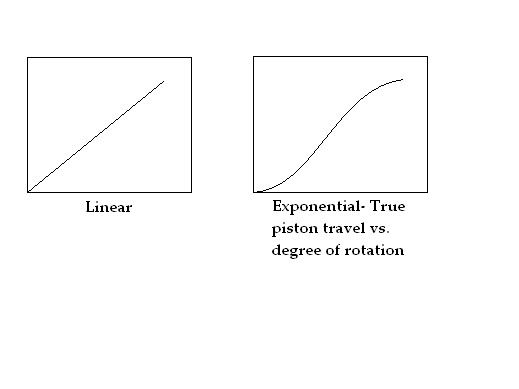

Found something else out, 1 deg equals about .026 in., so worrying about pulling the injector up too much with thicker gaskets and spraying out of the bowl is unfounded. With .052 thicker gasket you only artificially advance the timing be 2 deg. Well, back to the calculator. Jay

Found something else out, 1 deg equals about .026 in., so worrying about pulling the injector up too much with thicker gaskets and spraying out of the bowl is unfounded. With .052 thicker gasket you only artificially advance the timing be 2 deg. Well, back to the calculator. Jay