You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lets see pics of traction bars

- Thread starter alldiesels

- Start date

Unless variety is a specialization then no. Ok and good at many excellent at nothin reallyKeep your chin up!

Just save "absolute" opinions/statements to the areas in life that you specialize in...

I am sure there are some!

That was a quick and to the point experiment. The 2 3/8" tubing would that be considered a pretty good all around tube to be used for general building? Seeing as how it would be the same weight as 1" stock yet over 5 times as strong according to the equations. Now if only they taught useful equations like the ones you used in school instead. Well at least everyone knows what the truth is and diameter and weight are the important deciding factors.

I will save you the equations...

1 inch solid round...calculated to not yield at 32 inches with a 200lb force.

1 inch tube 0.113 wall...calculated to not yield at 23 inches with the same force...clearly yield at 32 inches.

Read more below.

Sorry for the horrible auto type...the hollow was 1"dia calcs to 23" before yield....so it clearly yielded at 32".

Its just M = SxFb

nskyline34

New member

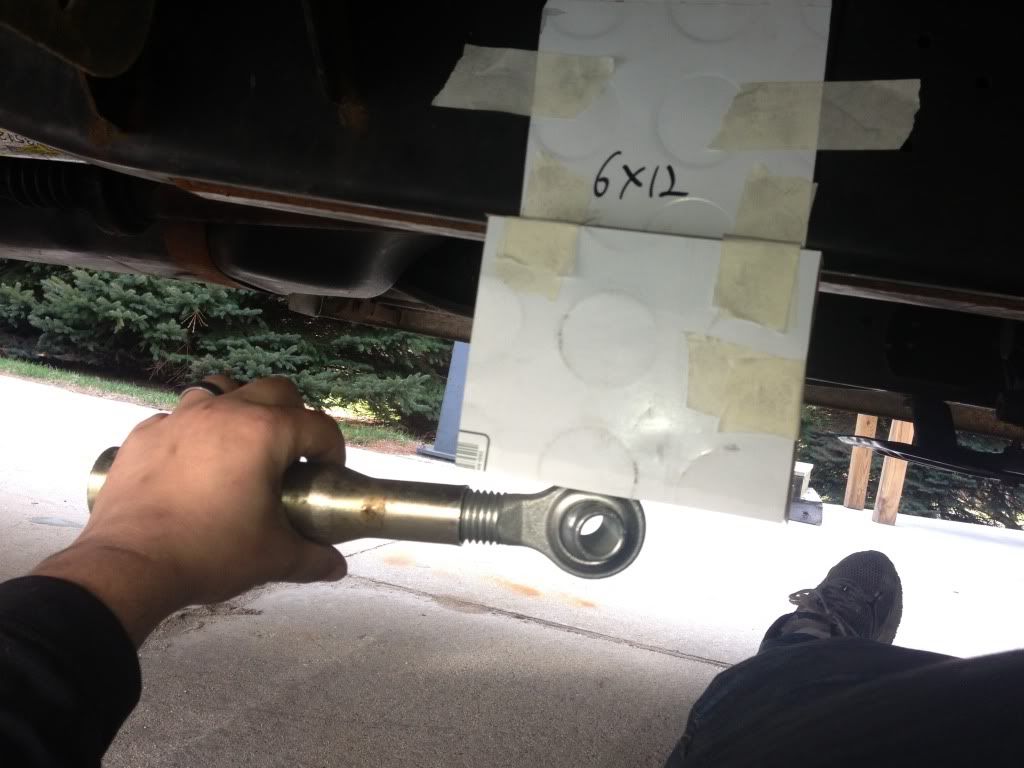

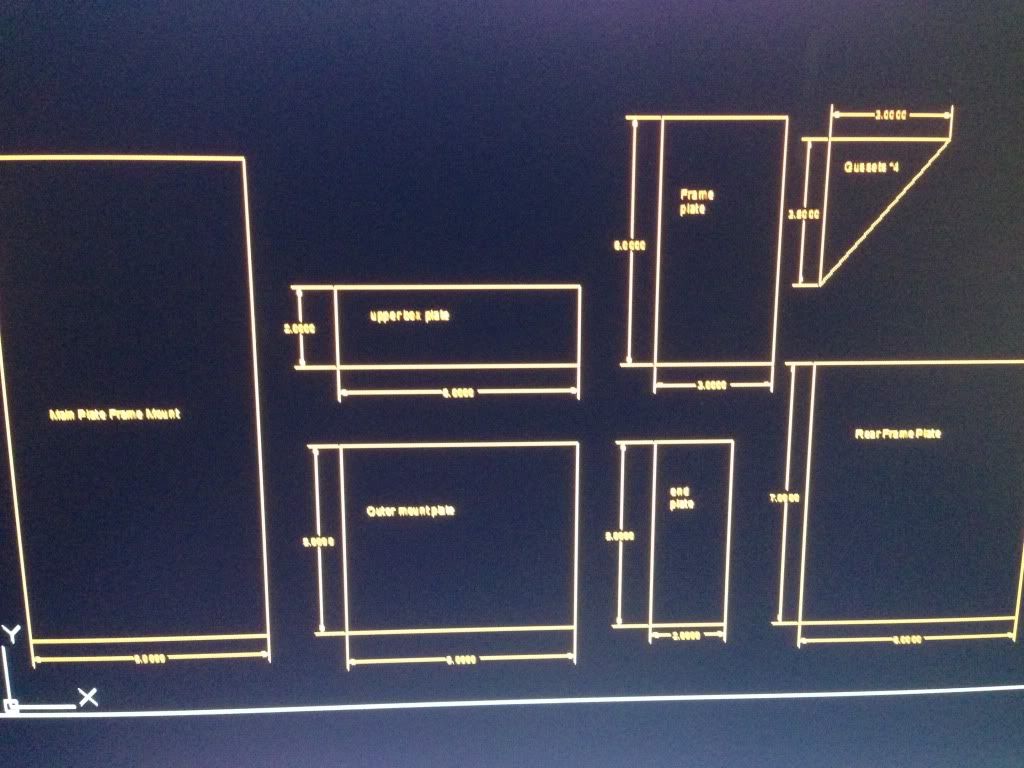

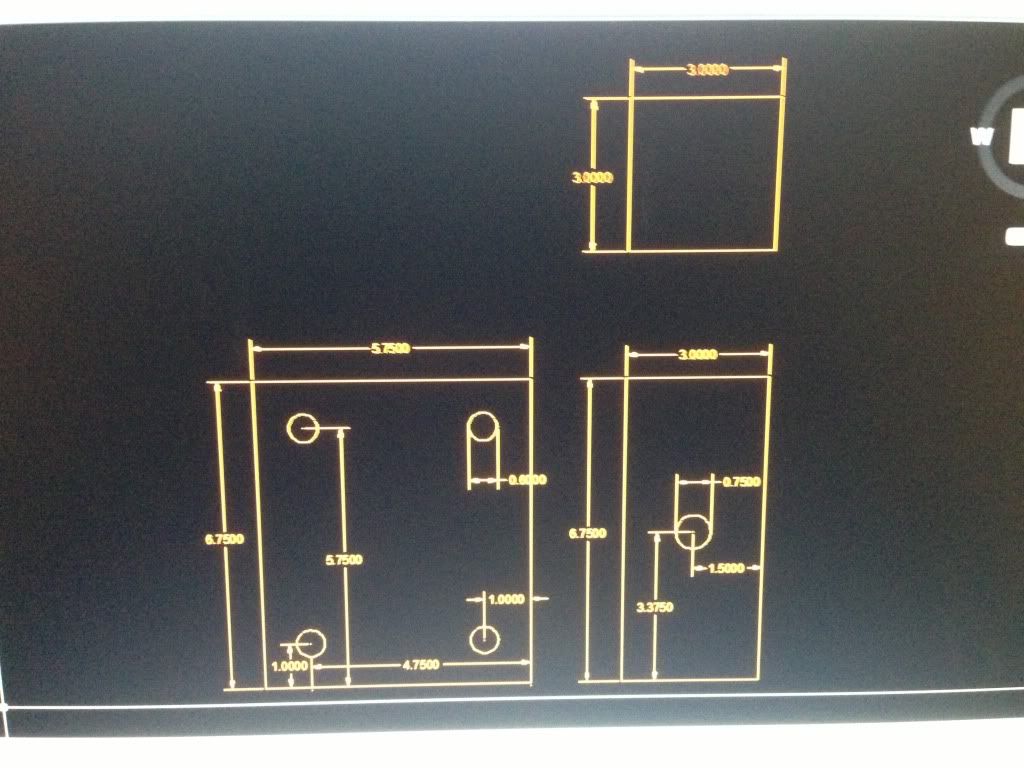

Hey guys, I have a 2001 ram that's a club can and long bed. I'm building some traction bars and cant decide on 7' or 8' bars, and if for mounting brackets if 1/4" is good?

Hey guys, I have a 2001 ram that's a club can and long bed. I'm building some traction bars and cant decide on 7' or 8' bars, and if for mounting brackets if 1/4" is good?

These questions are hard without knowing more about how your doing it.

Make a sketch...take a picture and post it...then i can mail tell you.

Done right...3/16 can work.

Make the bars parallel to the drive shaft...i think 7 ft is way too long.

Maybe its a second gen thing?

Chrisd91

New member

These questions are hard without knowing more about how your doing it.

Make a sketch...take a picture and post it...then i can mail tell you.

Done right...3/16 can work.

Make the bars parallel to the drive shaft...i think 7 ft is way too long.

Maybe its a second gen thing?

2nd gens aren't boxed all the way, I think that's why people want to run long bars on them