You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

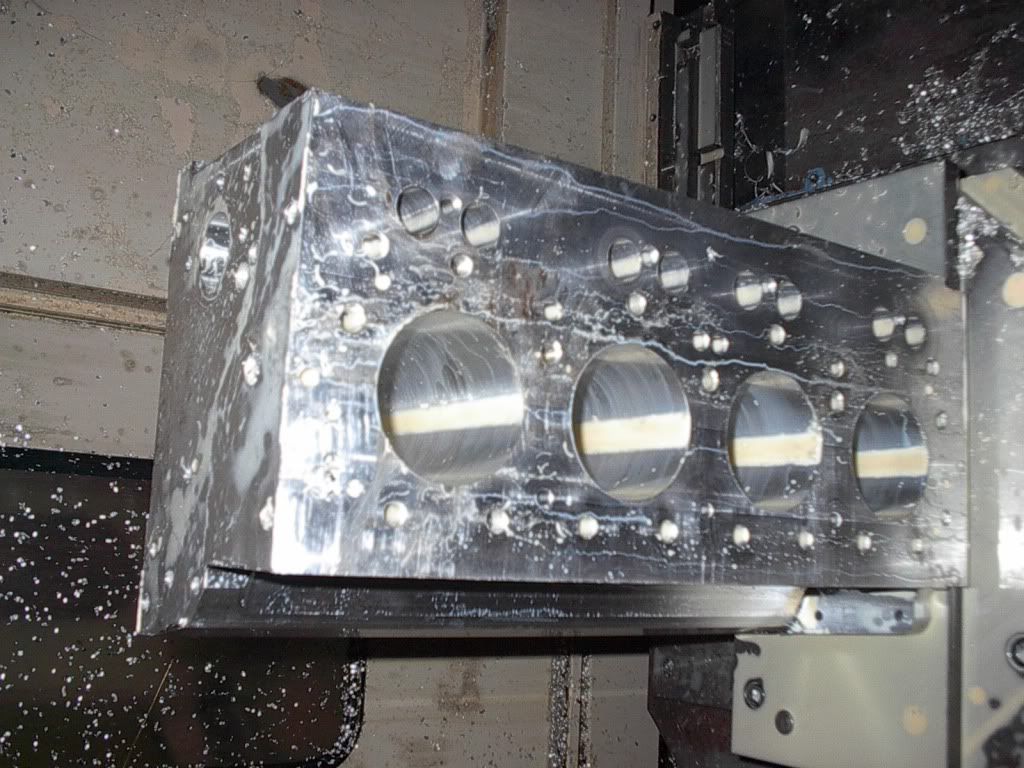

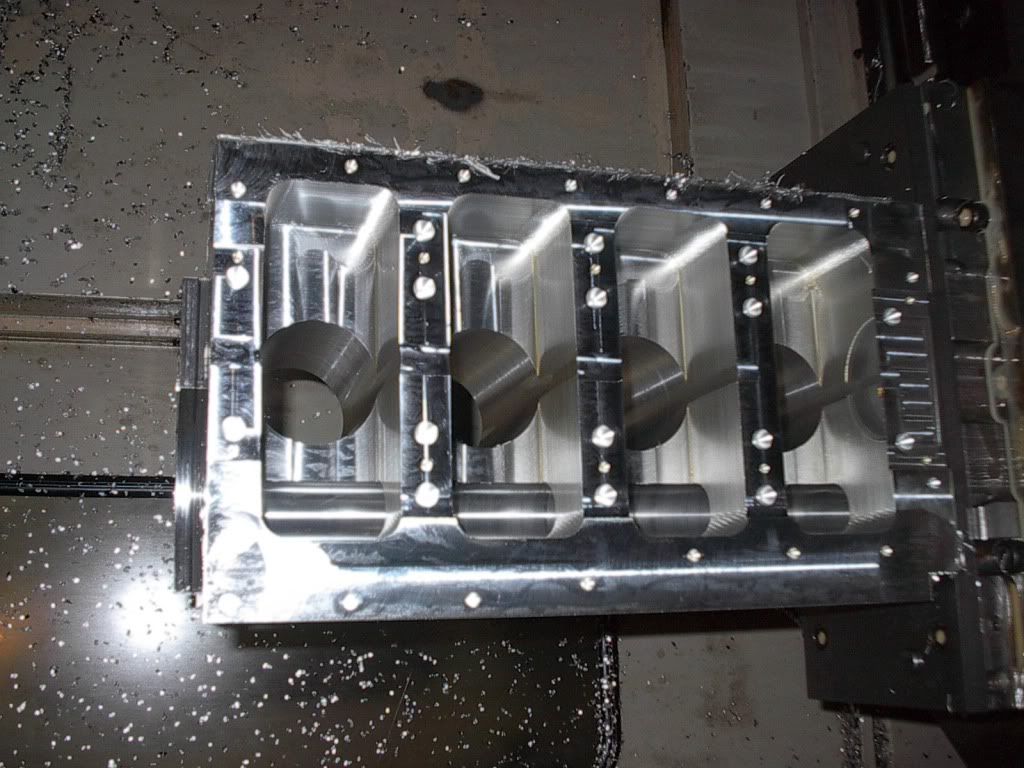

Lsm's Billet Aluminum Block

- Thread starter TMONEYDIESEL

- Start date

straight 6 roar

New member

- Joined

- Nov 7, 2010

- Messages

- 1,031

Last edited:

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

Im not the best with math, but Lets see here...

Billet BB chevy block $8000

Billet crank $2800

Roler Lifters $1800

adjustable cam drive or belt drive $200-1000

Custom camshaft $ 400-1000

Custom heads to fit Chevy bolt pattern and bore spacing..$2000-10000

Push rods $ 400

Valve covers $ 200-600

Custom fuel lines $??

And a few other surprises later you are in the red again greg! Your overthinking this way to much.

Now if you just purchased the billet block i have, you would have only spent $12,500 with lifters and everything else bolts right up!

And best of all you MIGHT be running by now.....

Good luck whatever you choose to do.

Good thing you gave the math disclaimer because I believe it is off actually.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

Im not the best with math, but Lets see here...

Billet BB chevy block $8000

Billet crank $2800 so your cranks are free

Roler Lifters $1800again your lifters are free, BBC roller lifter around$450

adjustable cam drive or belt drive $200-1000

Custom camshaft $ 400-1000 again your cams must be free

Custom heads to fit Chevy bolt pattern and bore spacing..$2000-10000 again your heads are free this uses stock Dmax cylinder heads with Dmax bolt pattern

Push rods $ 400 that magic fairy must give these to you free as well

Valve covers $ 200-600 your must be free , there are stock Dmax valve covers

Custom fuel lines $?? same as stock

And a few other surprises later you are in the red again greg! Your overthinking this way to much. well, no, I went with the top block people in the contry and let him do what he does best.

Now if you just purchased the billet block i have, you would have only spent $12,500 with lifters and everything else bolts right up!

And best of all you MIGHT be running by now.....

Good luck whatever you choose to do.

CN blocks build most of the blocks out there

as to the Cummins block, looks like a cheater block, why even try to make it look like a cummins. There is no other reason to mimic ever bump and knot on a stock block, but to try and slide it by tech with a good pain job

little6cylinder

Everything is "fixable"

- Joined

- Mar 7, 2011

- Messages

- 1,218

CN blocks build most of the blocks out there

as to the Cummins block, looks like a cheater block, why even try to make it look like a cummins. There is no other reason to mimic ever bump and knot on a stock block, but to try and slide it by tech with a good pain job

Painting a billet aluminum block is like tagging graffiti up all over heaven!

CN blocks build most of the blocks out there

as to the Cummins block, looks like a cheater block, why even try to make it look like a cummins. There is no other reason to mimic ever bump and knot on a stock block, but to try and slide it by tech with a good pain job

Can you be your female porn star persona for us? What was your/her name again.... Becky....:hehe:

TravisG

#THEREALLAVONMILLER

- Joined

- Aug 23, 2006

- Messages

- 6,803

Knowledge is key factor....stirring the pot just isnt needed in tech.

Huh? How is a guy drooling and wiping his mouth stirring the pot?

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

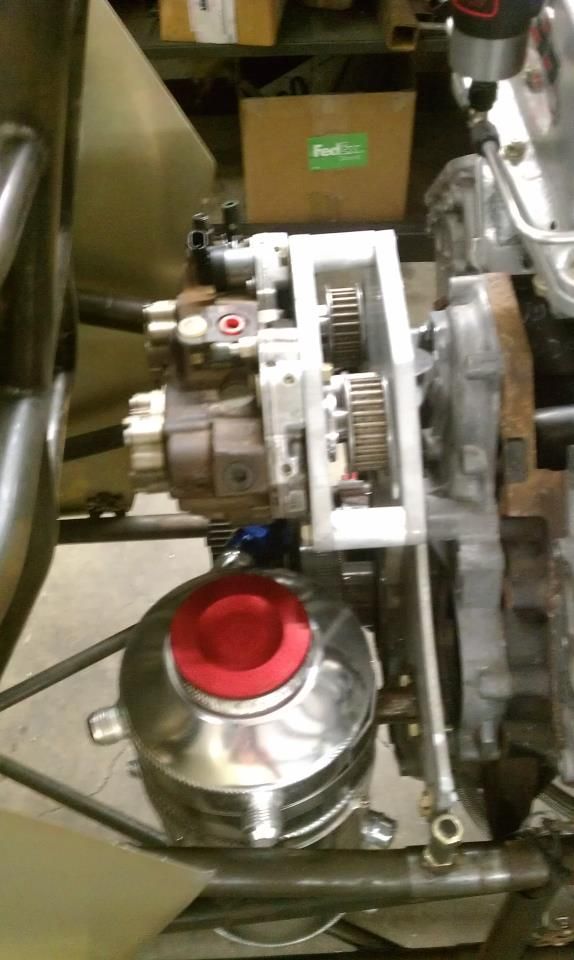

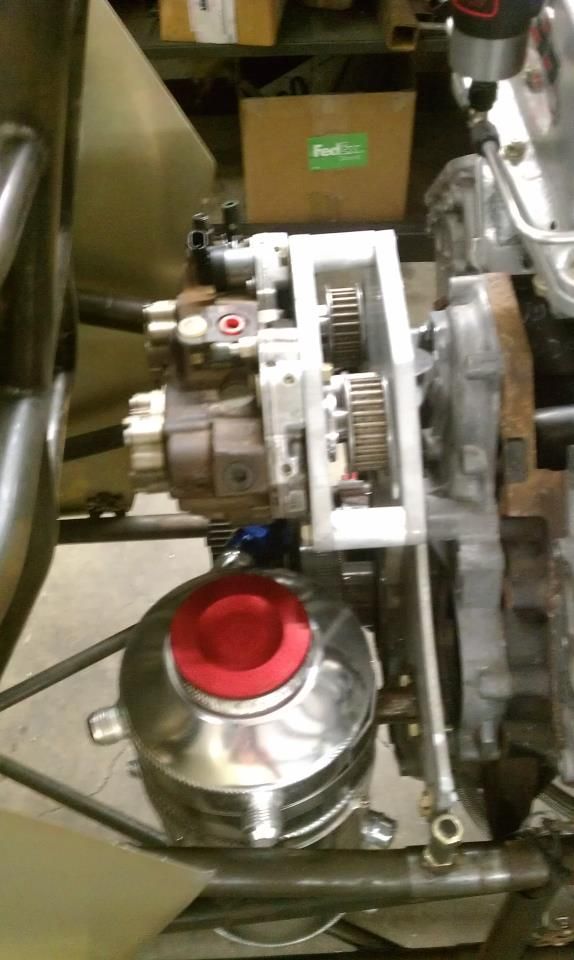

Got the crank on order today, $2700 for a 3.650 with BBC rod pins. I change the bore to 4.310 for a total 427. The intake valve on the Frankenstein heads will be a 1.52 with a 1.30 exhaust valve. There is a weeks’ worth of wielding on these heads to raise the ports.

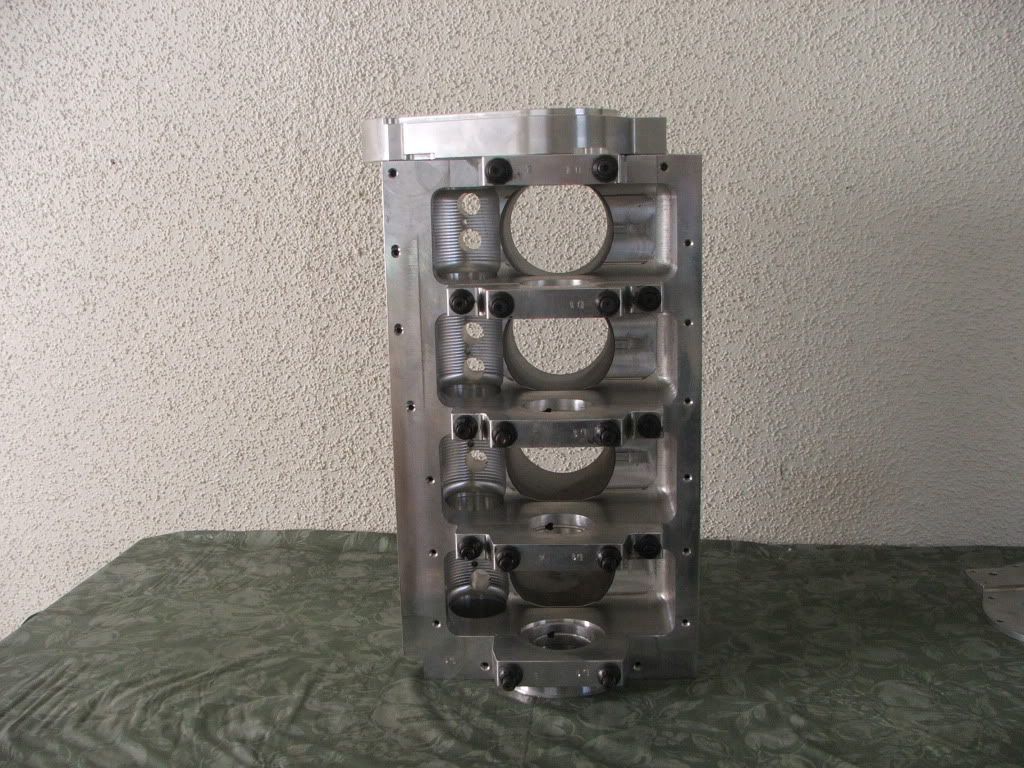

I talked to Chuck today about a Cummins clock, it would look nothing like a stock block, and here is what I would want, only in an inline 6.

To start make the cam at least 65 mm , no oil or water passing between the head and block. This would allow for nothing but a Garloc type ring set without a gasket.

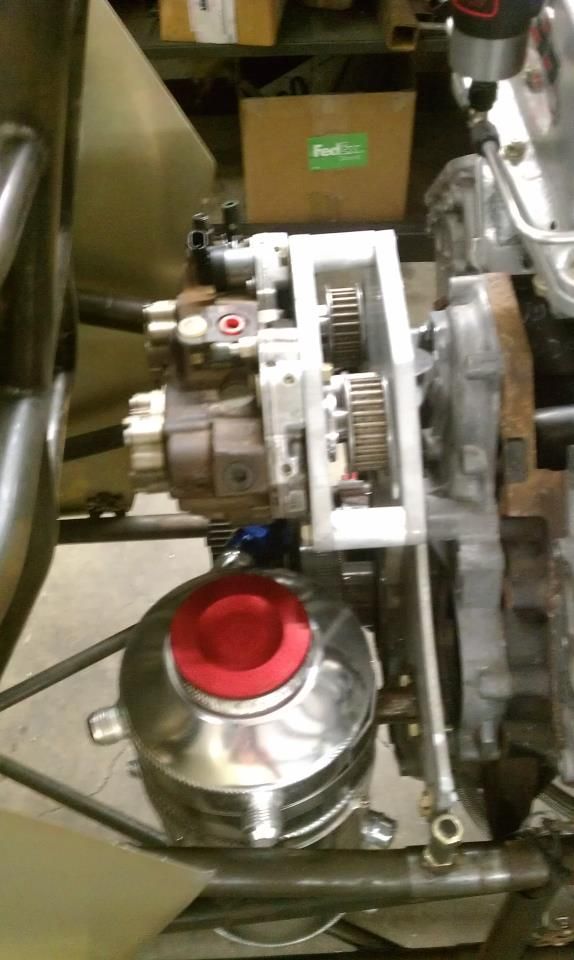

The only people wanting this block is drag racers so it need to have a Chevy bell-housing no need for a front cover drive the pumps with a belt drive off the cam like my drives on my dragster

I talked to Chuck today about a Cummins clock, it would look nothing like a stock block, and here is what I would want, only in an inline 6.

To start make the cam at least 65 mm , no oil or water passing between the head and block. This would allow for nothing but a Garloc type ring set without a gasket.

The only people wanting this block is drag racers so it need to have a Chevy bell-housing no need for a front cover drive the pumps with a belt drive off the cam like my drives on my dragster

CSnyder

Snyder-Motorsports

- Joined

- Mar 3, 2008

- Messages

- 6,278

Huh? How is a guy drooling and wiping his mouth stirring the pot?

post above mine Travis.

lenahan05

Comp Diesel Sponsor

- Joined

- Jan 31, 2009

- Messages

- 1,173

Got the crank on order today, $2700 for a 3.650 with BBC rod pins. I change the bore to 4.310 for a total 427. The intake valve on the Frankenstein heads will be a 1.52 with a 1.30 exhaust valve. There is a weeks’ worth of wielding on these heads to raise the ports.

I talked to Chuck today about a Cummins clock, it would look nothing like a stock block, and here is what I would want, only in an inline 6.

To start make the cam at least 65 mm , no oil or water passing between the head and block. This would allow for nothing but a Garloc type ring set without a gasket.

The only people wanting this block is drag racers so it need to have a Chevy bell-housing no need for a front cover drive the pumps with a belt drive off the cam like my drives on my dragster

GM midget block aint it? pretty sure we got one of these setting at the shop. neat little piece and make over 400hp N/A with very few cu.in.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

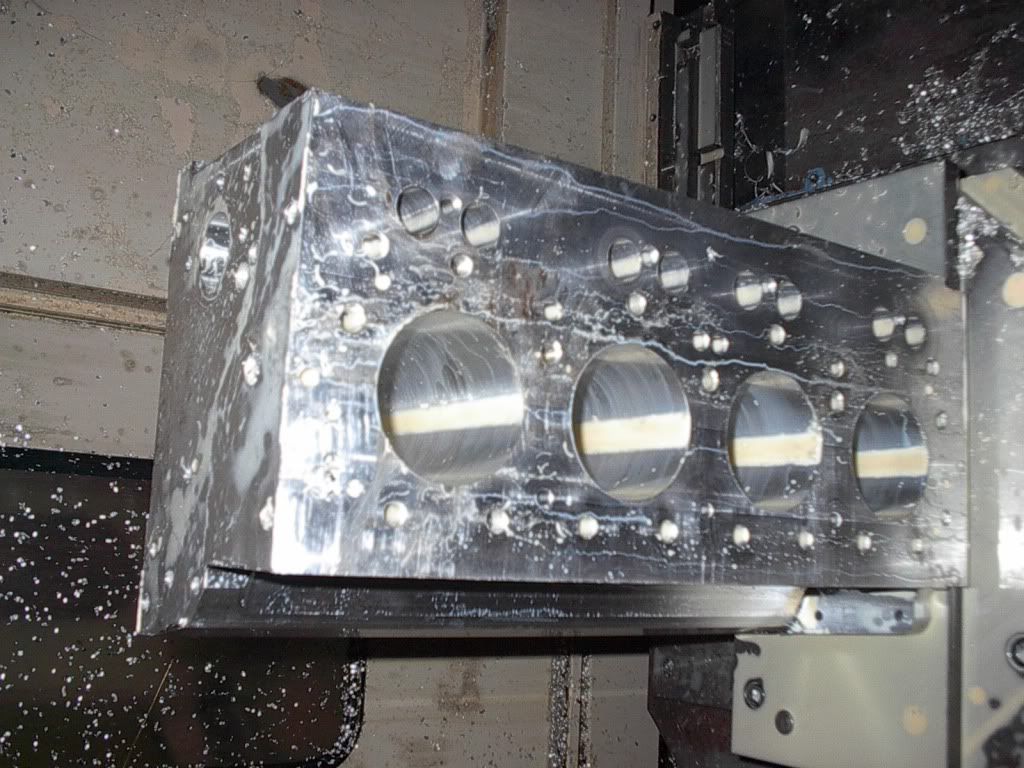

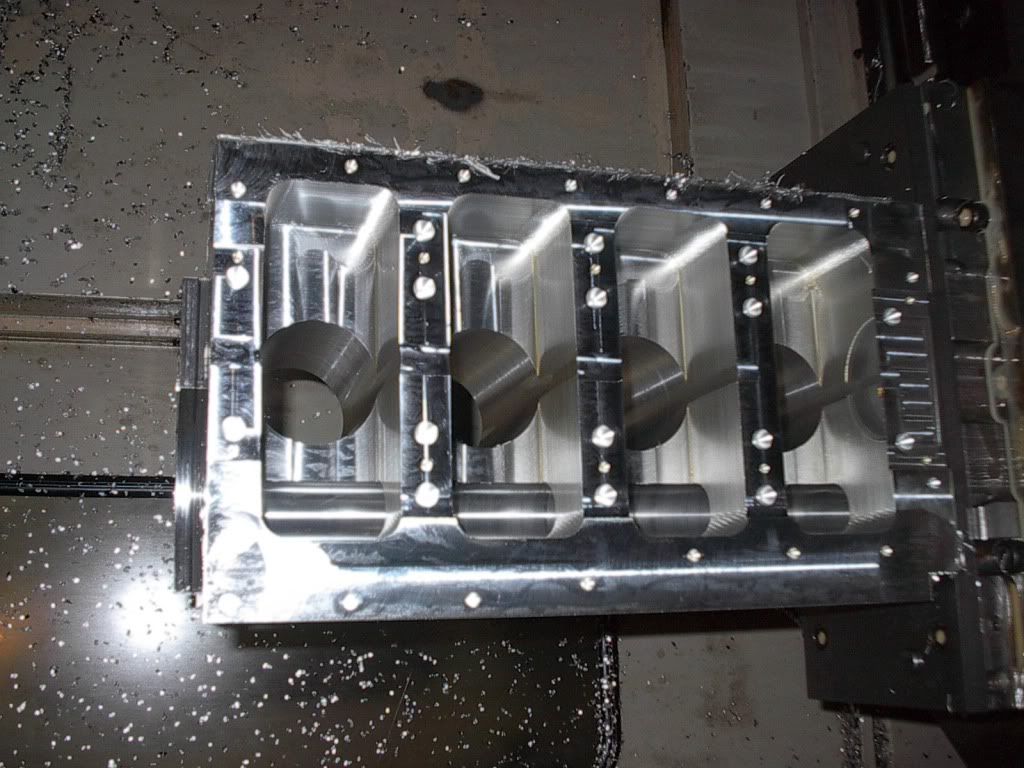

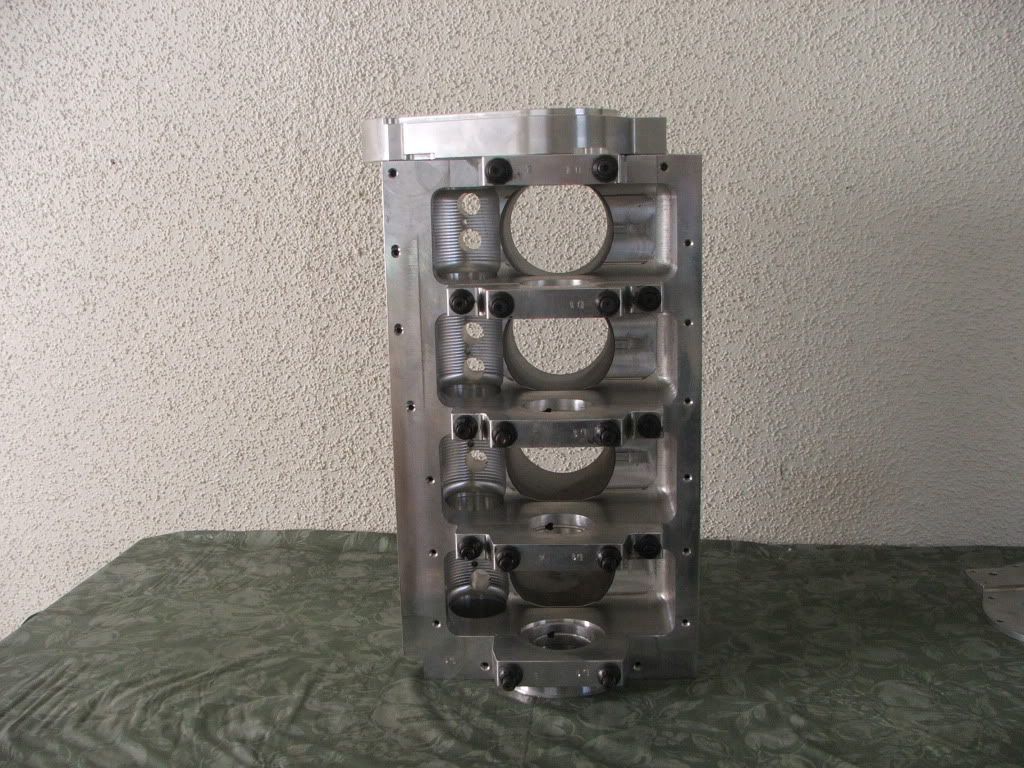

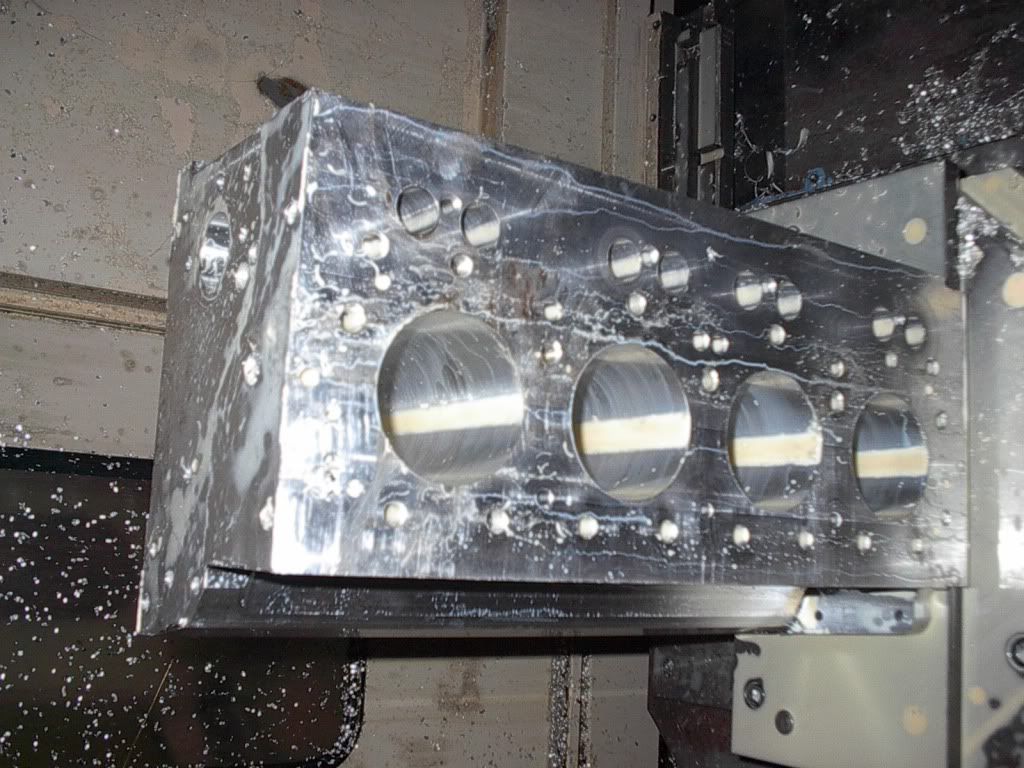

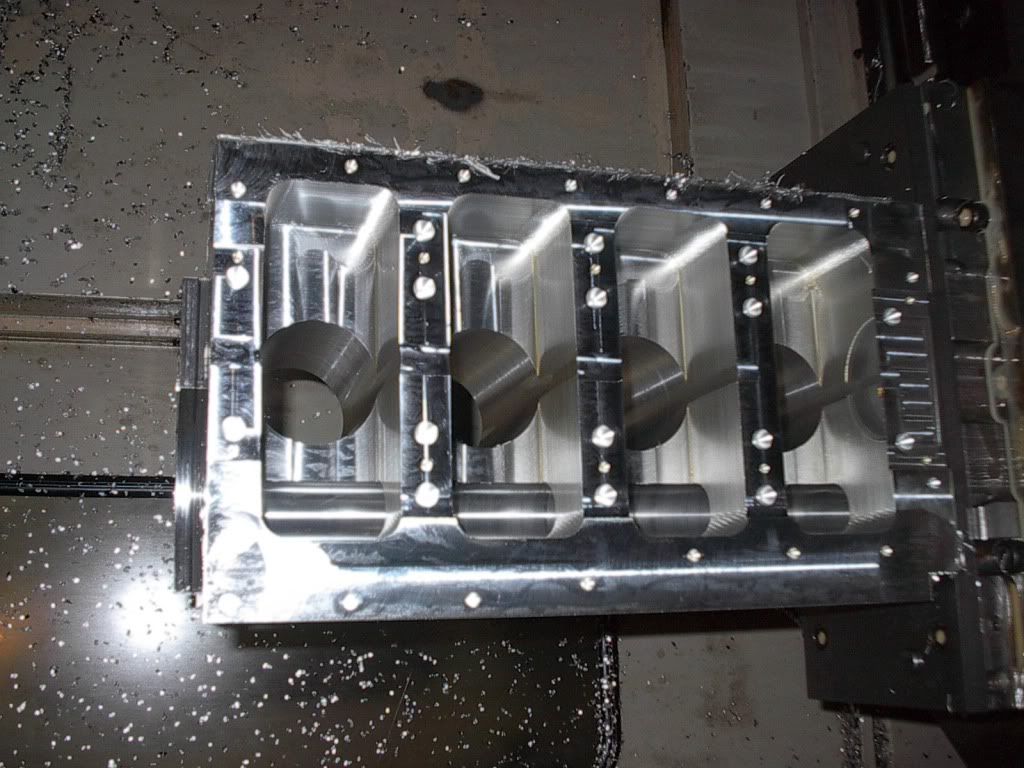

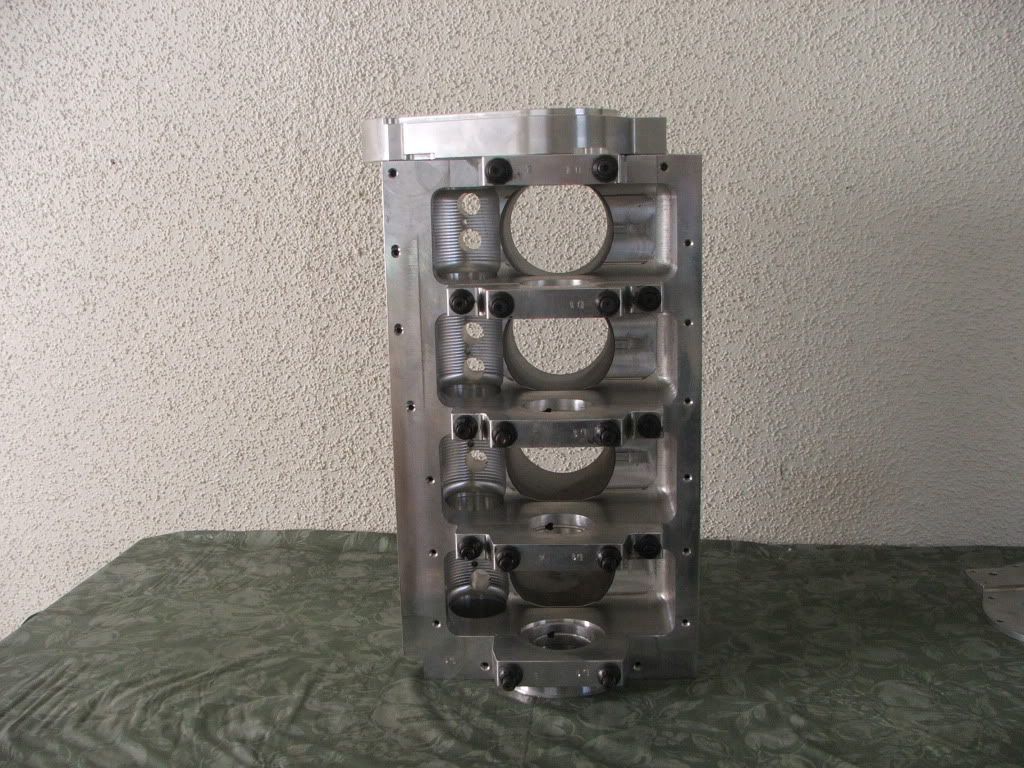

Yea, its 4.500 bore spacing for a Chevy splayed valve he built the block on my first inline program for E/ED and E/EA. On any kind of drag motor, i would take at least 2 inches of deck out of it, and use a 4.0 stroke like in my D/DT motor. Go with a 4.50 bore for a 388 cid motor. Aluminum block really don’t make the power a steel block does but the weight savings is the only reason. A stock Cummins CR block weighs 315 with main caps A Dmax weighs 287. The CN block should weigh about 145 with aluminum caps. The crank is 15 to 20 lbs. lighter than a Dmax crank. Weight savings is a really good thing, especially in my car at 1745 with driver, but this block makes power possible. With a big bore you can stuff bigger valves and unshroud them even more. The cam possibilities allow even more gain with 65mm cores. For reference Pro stock motors run a 78 mm cam.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

When I do a diesel head it will look like this Sonnies Chevy Hemi head , its flows close to 800 cfm, on a big bore spacing, do this head at 4.840 with smaller vlaves and use the spark plug as an injector location, if your going to do this , do it right,

I would put a smaller valve in it and move the placment to center, but still angled around the port

I would put a smaller valve in it and move the placment to center, but still angled around the port

When I do a diesel head it will look like this Sonnies Chevy Hemi head , its flows close to 800 cfm, on a big bore spacing, do this head at 4.840 with smaller vlaves and use the spark plug as an injector location, if your going to do this , do it right,

I would put a smaller valve in it and move the placment to center, but still angled around the port

To use this head. Do you plan to run bowl-less pistons? The valves are planted at an angle and the runners are short which help greatly with the extreme flow numbers. It definitely would take some custom nozzles!

Last edited:

TMONEYDIESEL

Comp Diesel Sponsor

- Joined

- Jan 21, 2007

- Messages

- 8,706

Blanks are available