You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My p pump swap.

- Thread starter yoshi470

- Start date

red dodge2

New member

- Joined

- Feb 12, 2008

- Messages

- 3,803

call pureflow. i bet they can get you what you need.:Cheer:

roachie

Taco Master

- Joined

- Nov 2, 2007

- Messages

- 11,133

Rollin Coal

Fabricator

- Joined

- Oct 25, 2008

- Messages

- 2,232

fragola, they are about 10 min from my house and have EVERYTHING

Fragola Performance Systems 460816 - Fragola Performance Systems AN to Metric Adapter Fittings - Overview - SummitRacing.com

will need an o ring or crush washer

Fragola Performance Systems 460816 - Fragola Performance Systems AN to Metric Adapter Fittings - Overview - SummitRacing.com

will need an o ring or crush washer

Rollin Coal

Fabricator

- Joined

- Oct 25, 2008

- Messages

- 2,232

actually i have a few of them here if you dont wanna pay summits handling fee

NickTF

Single turbo turd.

- Joined

- Jun 4, 2007

- Messages

- 5,887

gonna put my 40psi spring in my airdog today. Where exactly is this spring located at?

IIRC it's right behind fitting which threads into the port return fuel comes out of.

yoshi470

EDP Janitor

- Joined

- Jun 30, 2008

- Messages

- 1,432

ok another question.

I put my push rods back in and rocker arms on and started to adjust my valves, only did the first two. Just wondering if there can still be some play in the push rod like between the adjustment stud and tappet? if that makes sense.

Also whats the best way to find TDC? Right now i just took a screwdriver and stuck it down the injector hole and got it as close as possible. Thanks for the help

I put my push rods back in and rocker arms on and started to adjust my valves, only did the first two. Just wondering if there can still be some play in the push rod like between the adjustment stud and tappet? if that makes sense.

Also whats the best way to find TDC? Right now i just took a screwdriver and stuck it down the injector hole and got it as close as possible. Thanks for the help

yoshi470

EDP Janitor

- Joined

- Jun 30, 2008

- Messages

- 1,432

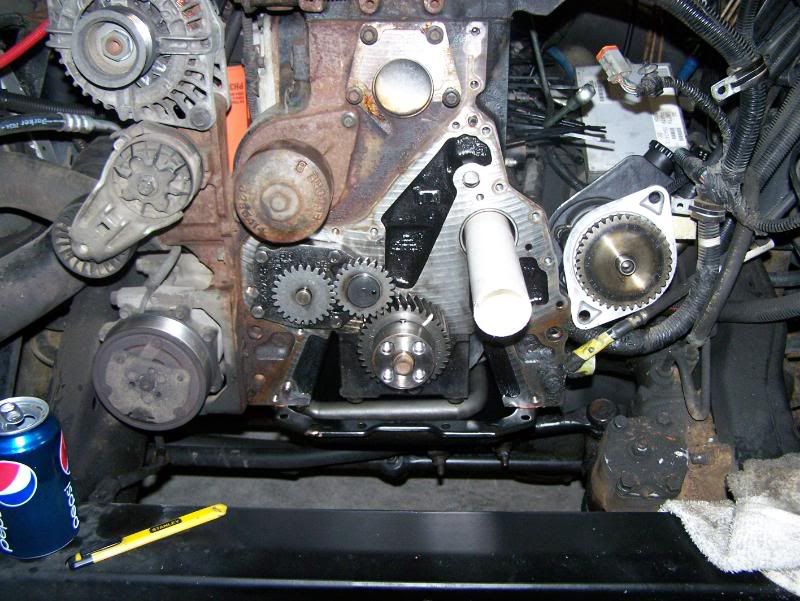

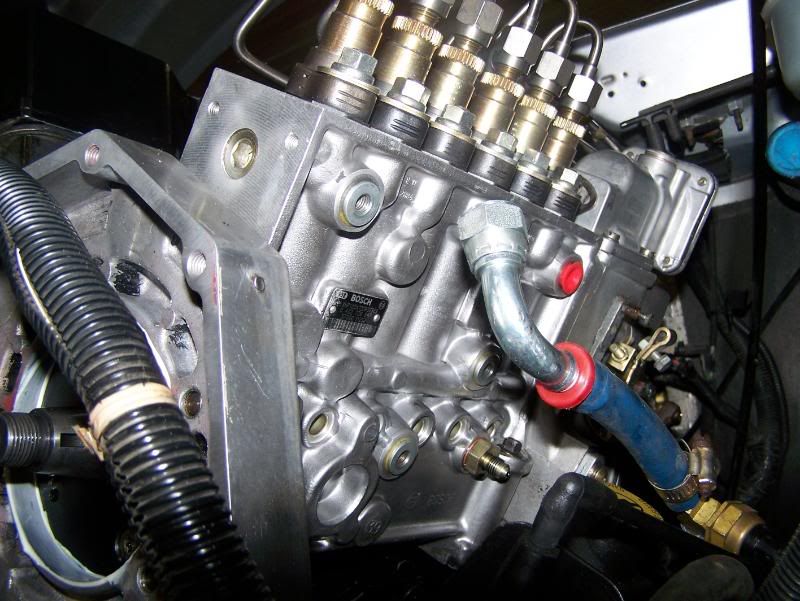

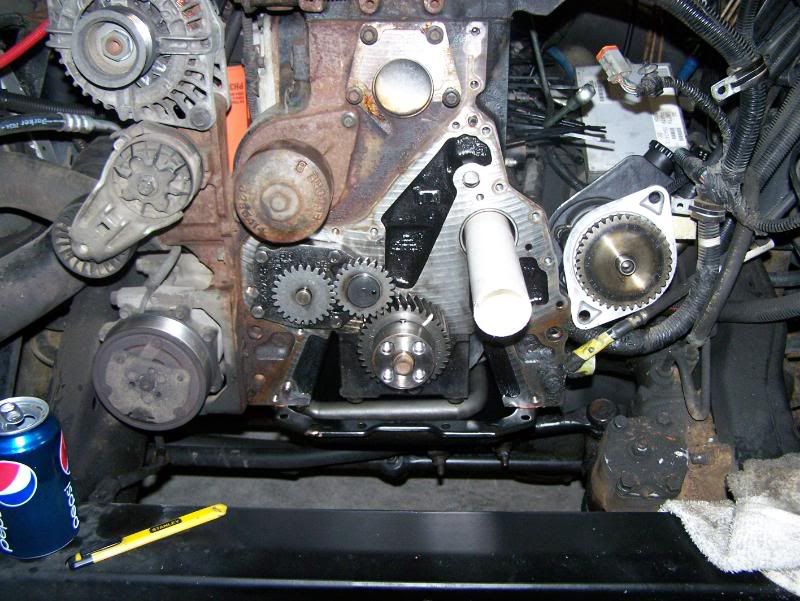

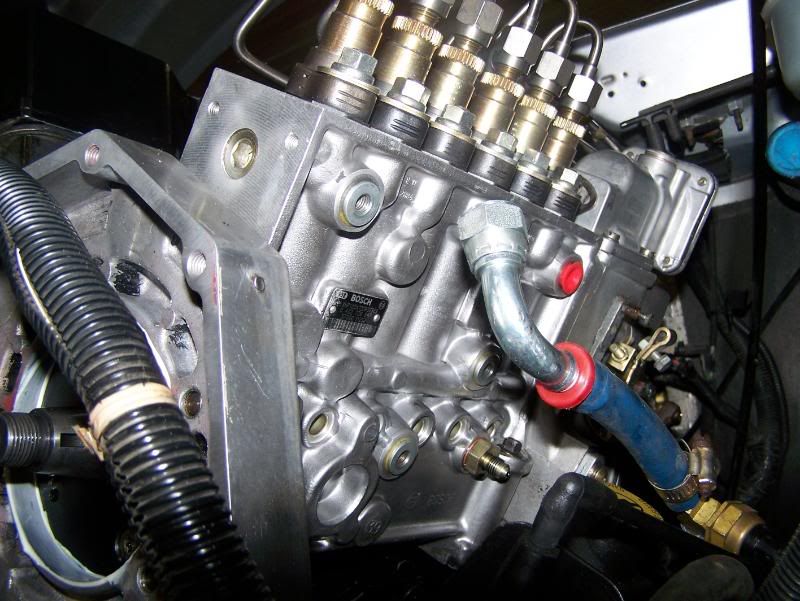

getting some more done. heres a few more pics

So far the most frustrating thing of the whole project has been the fuel lines, spent nearly 2 hours today trying to get them right and where i wanted and im still not happy and some wont even screw in the head all the way. Taking them off again tomorrow and gonna try tweaking them again, i cant believe scheids cant do a little bit better job on them...

So far the most frustrating thing of the whole project has been the fuel lines, spent nearly 2 hours today trying to get them right and where i wanted and im still not happy and some wont even screw in the head all the way. Taking them off again tomorrow and gonna try tweaking them again, i cant believe scheids cant do a little bit better job on them...

Warpig

12V killer

- Joined

- Aug 29, 2007

- Messages

- 1,067

So far the most frustrating thing of the whole project has been the fuel lines, ..

Welcome to the club!!!

yoshi470

EDP Janitor

- Joined

- Jun 30, 2008

- Messages

- 1,432

I forgot to say if you are handy with a sawzall I can send you some pics that will make the pump mounting bolts ALOT easier.

Maybe i should come show you how to turn a wrench pete? LOL

In all seriousness though i already got them all tightened up without cutting anything, just used a swivel on my socket along with a magnet to get it start on the nut and it wasnt bad at all. Cutting anything was my last option

And can anyone answer my question about my pushrods, a few posts up

yoshi470

EDP Janitor

- Joined

- Jun 30, 2008

- Messages

- 1,432

If you mean up and down play I would see how adjusting them wouldn't take that out.

Yea its up and down play when they are set correctly. I just didnt remember if they were like then when i took it apart or not, just wanna make sure its normal

red dodge2

New member

- Joined

- Feb 12, 2008

- Messages

- 3,803

what timing are you planning on running? also what about the dv's?

Tate

What?

- Joined

- Nov 5, 2007

- Messages

- 3,419

Maybe i should come show you how to turn a wrench pete? LOL

In all seriousness though i already got them all tightened up without cutting anything, just used a swivel on my socket along with a magnet to get it start on the nut and it wasnt bad at all. Cutting anything was my last option

And can anyone answer my question about my pushrods, a few posts up

The real *****y nut on the pump, you should be able to get at it from underneath the pump. I guess if it depends if you have sausages for fingers though.

Just make sure all your pushrods are seated in the tappet, and then lash all your valves. They should be close, but don't assume they are. If the rocker is pressing against the bridge, then there will be a little bit of play between the rocker and the push rod, assuming that its on the base circle of the cam.