You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New engine build Scania DC1601 for our semi truckpuller.

- Thread starter tall boy

- Start date

Leiffi

New member

- Joined

- Jan 31, 2013

- Messages

- 1,381

Well it must be a thing happening in Finland as Herlevi telling the same story about the Euro4 and cams two weeks ago thinking to make more power asking me a bout getting more fuel and what advance timing to run but as we moved to a different camshaft profile end of 2012 I could not help him.

We are working on new DC16 PDE Cams that will support a 16.8mm plunger travel and for this you need to modify the Euro 3 injectors or the Euro 4/5 injectors but this all needs to be tested and with all the new things going in build up face this will take some time before we get to do this. Also the question is are we going to release them for commercial use?

1000hp reached with Euro4 cam in a working truck, not bad for a bad camshaft ?

Going back to the original thing on upgrading from a V8 Euro 3 spec engine to a V8 Euro 4 dos not make improvement and yes these engines make 1000Hp easy that’s nothing new.

The only comment I’m making on things is that assuming things is not the best thing to do and better get data on an engine and hope to have the know how to work things out.

We have done this whole lot back in 2012 sorting out engine specifications including building a 12mm plunger PDE prototype injector knowing that BOSCH did build a 11mm plunger PDE and knowing that OE race engines of all brands using BOSCH PDE all run 10mm plungers so we fail in building one that did perform in a good way so that was a no go but not a lot of money and time spend on it. Last year we tested 8 PDE injectors build by a diesel repair shop with a bigger plunger as well that did not perform @ all, same thing No Go.

So we now know what we did wrong for the last years. Thing now is to come up with a better camshaft but we know that this will be very complicated as we need to combine 3 sets of cams on one shaft having no room for error. It’s about time we did jump over to a commonrail XPI but not many around or out of budged range. LOL

Single runner per cylinder exhaust manifolds do there job very well on both semi The original engine dos 4.6Bar boost and the generation 2 engine makes 5,1Bar of boost as last year this engine run only 4,2Bar boost with the old manifolds. Same turbo type are used on the generation 2 engine and the original engine runs same compressor but bigger turbine configuration.

[ame="http://www.youtube.com/watch?v=-mKu-Ew016A"]http://www.youtube.com/watch?v=-mKu-Ew016A[/ame]

[ame="http://www.youtube.com/watch?v=bjVQJvlXuVk"]http://www.youtube.com/watch?v=bjVQJvlXuVk[/ame]

[ame="http://www.youtube.com/watch?v=1ebv9BNRR7g"]http://www.youtube.com/watch?v=1ebv9BNRR7g[/ame]

[ame="http://www.youtube.com/watch?v=_YLWJdVUaL8"]http://www.youtube.com/watch?v=_YLWJdVUaL8[/ame]

[ame="http://www.youtube.com/watch?v=2DGOnCrVcNM"]http://www.youtube.com/watch?v=2DGOnCrVcNM[/ame]

[ame="http://www.youtube.com/watch?v=m65g7gwlzjk"]http://www.youtube.com/watch?v=m65g7gwlzjk[/ame]

[ame="http://www.youtube.com/watch?v=_qivLeGbs2E"]http://www.youtube.com/watch?v=_qivLeGbs2E[/ame]

[ame="http://www.youtube.com/watch?v=Cpi04NnIA6k"]http://www.youtube.com/watch?v=Cpi04NnIA6k[/ame]

The only comment I’m making on things is that assuming things is not the best thing to do and better get data on an engine and hope to have the know how to work things out.

We have done this whole lot back in 2012 sorting out engine specifications including building a 12mm plunger PDE prototype injector knowing that BOSCH did build a 11mm plunger PDE and knowing that OE race engines of all brands using BOSCH PDE all run 10mm plungers so we fail in building one that did perform in a good way so that was a no go but not a lot of money and time spend on it. Last year we tested 8 PDE injectors build by a diesel repair shop with a bigger plunger as well that did not perform @ all, same thing No Go.

So we now know what we did wrong for the last years. Thing now is to come up with a better camshaft but we know that this will be very complicated as we need to combine 3 sets of cams on one shaft having no room for error. It’s about time we did jump over to a commonrail XPI but not many around or out of budged range. LOL

Single runner per cylinder exhaust manifolds do there job very well on both semi The original engine dos 4.6Bar boost and the generation 2 engine makes 5,1Bar of boost as last year this engine run only 4,2Bar boost with the old manifolds. Same turbo type are used on the generation 2 engine and the original engine runs same compressor but bigger turbine configuration.

[ame="http://www.youtube.com/watch?v=-mKu-Ew016A"]http://www.youtube.com/watch?v=-mKu-Ew016A[/ame]

[ame="http://www.youtube.com/watch?v=bjVQJvlXuVk"]http://www.youtube.com/watch?v=bjVQJvlXuVk[/ame]

[ame="http://www.youtube.com/watch?v=1ebv9BNRR7g"]http://www.youtube.com/watch?v=1ebv9BNRR7g[/ame]

[ame="http://www.youtube.com/watch?v=_YLWJdVUaL8"]http://www.youtube.com/watch?v=_YLWJdVUaL8[/ame]

[ame="http://www.youtube.com/watch?v=2DGOnCrVcNM"]http://www.youtube.com/watch?v=2DGOnCrVcNM[/ame]

[ame="http://www.youtube.com/watch?v=m65g7gwlzjk"]http://www.youtube.com/watch?v=m65g7gwlzjk[/ame]

[ame="http://www.youtube.com/watch?v=_qivLeGbs2E"]http://www.youtube.com/watch?v=_qivLeGbs2E[/ame]

[ame="http://www.youtube.com/watch?v=Cpi04NnIA6k"]http://www.youtube.com/watch?v=Cpi04NnIA6k[/ame]

Leiffi

New member

- Joined

- Jan 31, 2013

- Messages

- 1,381

Going back to the original thing on upgrading from a V8 Euro 3 spec engine to a V8 Euro 4 dos not make improvement and yes these engines make 1000Hp easy that’s nothing new.

The only comment I’m making on things is that assuming things is not the best thing to do and better get data on an engine and hope to have the know how to work things out.

So why is it that no one got any real power out of Euro3 engine without smoke and EGT problems ?

So why is it that no one got any real power out of Euro3 engine without smoke and EGT problems ?

You better tell us as you are the one messing around with working trucks knowing everything. Did you put some effort in to getting data on the pump cam lift profile on Euro 4 engines? Not injector travel only making an assumption?

We used the OE nozzle listed as 800Kw in the bosch documentation for marine engines running the same cams as the DC1601 engine and 800Kw is about 1088Hp? Being a OE application thing it will run within normal limits. Maybe you need a bit of extra fresh air to get this working for you? Sober up man.

Leiffi

New member

- Joined

- Jan 31, 2013

- Messages

- 1,381

I'm not messing with those, my friends are. They couldnt use enough timing advance with Euro3 cam to run clean.You better tell us as you are the one messing around with working trucks knowing everything. Did you put some effort in to getting data on the pump cam lift profile on Euro 4 engines? Not injector travel only making an assumption?

We used the OE nozzle listed as 800Kw in the bosch documentation for marine engines running the same cams as the DC1601 engine and 800Kw is about 1088Hp? Being a OE application thing it will run within normal limits. Maybe you need a bit of extra fresh air to get this working for you? Sober up man.

Why waste more energy pushing extra air into engine if you can do it with less air and more timing advance ?

Are you 100% sure 1000 hp marine engine is using Euro3 cam ?

I'm not messing with those, my friends are. They couldnt use enough timing advance with Euro3 cam to run clean.

Why waste more energy pushing extra air into engine if you can do it with less air and more timing advance ?

Are you 100% sure 1000 hp marine engine is using Euro3 cam ?

Yes up to , IMO Tier II, US Tier 2, EU stage III rated up to 2822Nm and it had a CR of 16:1 on industrial and propulsion applications as the truck engine has a CR of 18:1

Al do the civilian marine version was rated @ 800Hp 2200Rpm the military or short engine did a lot more but not documented but it run 2300RPM up to 2400RPM.

In preparation for the libya-rally we did some testing adding more low end fuel @ low boost and it did help a lot but get a bit of smoke for 1 second if you floor it from zero to max torque request.

We also used the biggest turbo allowed for rally use with a 74mm inducer size compressor without the need for an inlet restrictor.

From the data it shows that the spool up of the 82/88 turbine with a bigger 1.00A/R is only marginal slower than the 74/83 and turbine wheel and TH 1.10A/R on sea level so inertia plays a big part but as the air gets thinning by gaining altitude this will chance and the 74/83 turbine will perform a lot better than it’s bigger brother.

The job for tomorrow will be to make changes to the software setting of the 13L Scania XPI race engine. The engine is now build to specifications and I did get data from the runs they made but the O2 sensor was not working so no feedback on that part on what is left on oxygen.

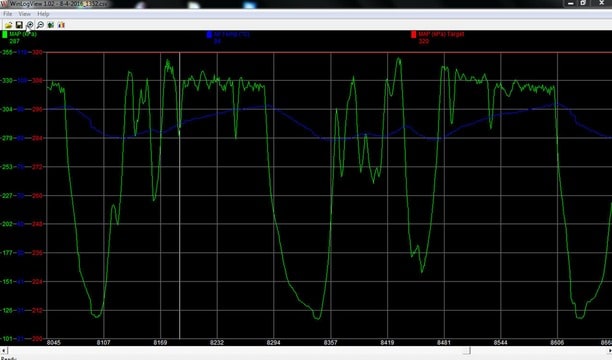

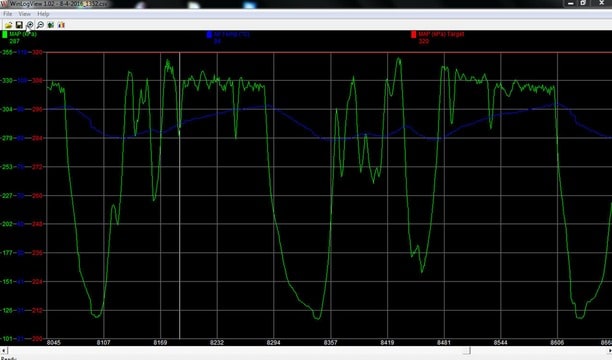

Also getting in correct data can be frustrating. There is a data logger getting data from the ECU and we also have the internal data from the ECU and it’s not a easy job to sync these and find out the data logger of the truck can not keep up with a part of the data stream coming from the ECU.

Than there is the thing that a race driver is not a test engineer. I want a pull from 1200Rpm up to the red line in 4 gear if possible. What do you get? A run from second gear to 5 gear up to 160Kmh where the speed limiter kicks in and a RPM drop to 2000Rpm by shifting gear only 800Rpm short of what I need on low end spool up data. Sometimes you want to reprogram the driver as well. LOL.

For some time we now testing the 88/96 BW turbine set-up with a 1.15A/R and 0.93A/R TH.

The 1.15A/R will be on sale already and the 0.93A/R TH is something we build in house.

The 88/96 BW turbine set-up with a 0.93A/R TH work well on a 16L OE set-up converting more power @ less EMP but we did not find the time to prepare a turbo for the 13L XPI Scania race truck engine to find out if this turbine set-up can overcome the inertia of the increased mass compared to the 82/92 and 82/88 turbine wheel we normally use.

Also making so many changes in one go can make things complicated on what has been changes and why so one step @ the time for now will be better.

[ame="http://www.youtube.com/watch?v=J5w2YfazA3A"]http://www.youtube.com/watch?v=J5w2YfazA3A[/ame]

We also used the biggest turbo allowed for rally use with a 74mm inducer size compressor without the need for an inlet restrictor.

From the data it shows that the spool up of the 82/88 turbine with a bigger 1.00A/R is only marginal slower than the 74/83 and turbine wheel and TH 1.10A/R on sea level so inertia plays a big part but as the air gets thinning by gaining altitude this will chance and the 74/83 turbine will perform a lot better than it’s bigger brother.

The job for tomorrow will be to make changes to the software setting of the 13L Scania XPI race engine. The engine is now build to specifications and I did get data from the runs they made but the O2 sensor was not working so no feedback on that part on what is left on oxygen.

Also getting in correct data can be frustrating. There is a data logger getting data from the ECU and we also have the internal data from the ECU and it’s not a easy job to sync these and find out the data logger of the truck can not keep up with a part of the data stream coming from the ECU.

Than there is the thing that a race driver is not a test engineer. I want a pull from 1200Rpm up to the red line in 4 gear if possible. What do you get? A run from second gear to 5 gear up to 160Kmh where the speed limiter kicks in and a RPM drop to 2000Rpm by shifting gear only 800Rpm short of what I need on low end spool up data. Sometimes you want to reprogram the driver as well. LOL.

For some time we now testing the 88/96 BW turbine set-up with a 1.15A/R and 0.93A/R TH.

The 1.15A/R will be on sale already and the 0.93A/R TH is something we build in house.

The 88/96 BW turbine set-up with a 0.93A/R TH work well on a 16L OE set-up converting more power @ less EMP but we did not find the time to prepare a turbo for the 13L XPI Scania race truck engine to find out if this turbine set-up can overcome the inertia of the increased mass compared to the 82/92 and 82/88 turbine wheel we normally use.

Also making so many changes in one go can make things complicated on what has been changes and why so one step @ the time for now will be better.

[ame="http://www.youtube.com/watch?v=J5w2YfazA3A"]http://www.youtube.com/watch?v=J5w2YfazA3A[/ame]

Indoor Pulling Assen.

Finally we could test the new 16.4L V8 engine and al do I do not have data on these pulls as I was on the circuit Brands Hatch England to assist two truck race teams the first impression I get by looking @ this Youtube that this engine is breathing a lot better than the generation 2 15.6L engine. Looks like the new cams turbochargers and manifolds are performing well.

[ame="http://www.youtube.com/watch?v=Kuv1Rbi4FY4"]http://www.youtube.com/watch?v=Kuv1Rbi4FY4[/ame]

Finally we could test the new 16.4L V8 engine and al do I do not have data on these pulls as I was on the circuit Brands Hatch England to assist two truck race teams the first impression I get by looking @ this Youtube that this engine is breathing a lot better than the generation 2 15.6L engine. Looks like the new cams turbochargers and manifolds are performing well.

[ame="http://www.youtube.com/watch?v=Kuv1Rbi4FY4"]http://www.youtube.com/watch?v=Kuv1Rbi4FY4[/ame]

Brands Hatch circuit last weekend.

Rainbow Warrior Truck Racing team . A load of work to redo a lot of modifications to the engine.

As always communication is vital between the team and us to avoid problems. If you update parts on an engine most of the time it will only work if other engines parts are not changed and in this case 2 things were changed on the race engine resulting in smoke hi EMP and EGT 200Rpm less max torque so in general not a good performing engine but we worked things out before the first race and after the second start due to a red flag they hold second position but being the BTRA thing go full contact on the track so red flag again as to many when of the track and on the start grit the technical comity went a bit nervous as one of the rims had a small dent in it so they where taken out of the race.

During the remaining 4 racing I mange to optimise timing and fuel pressure up to a point that the commonrail fuel pump is @ it’s max delivery and still no smoke and 16AFR even hi up the RPM range so I’m happy. On a dry circuit we still 2 seconds slower that Nr 1 truck mainly due to better traction but yes these are factory build FIA race trucks.

Engine mid en top end power is there but need to start working on anti turbo lag by adding post injections but this can be a tricky thing to spool the turbo when power request is zero.

Same thing can be done by left feet breaking while controlling boost/engine power with the accelerator peddle but the driver was unable to do this on the first bent after start as he goes in to aggressive in to the turn unable to left feet break and build boost on the downhill side of the bent lacking boost and power on the uphill part after so that’s where we lost time.

Last race was all wet on the track holding second place until the last round. Power lost after the first bent was solved as going in slower in to the bent able to apply engine power sooner building full boost and torque pulling as hard a the factor spec engines.

Also nice to hear the commentator say Scania leader of the MAN race pack.LOL

To bad as in the last round the driver made a small mistake with breaking losing 3 places ending up in 5 position but well this is close racing.

[ame="http://www.youtube.com/watch?v=E7ZNRLBE4Iw"]http://www.youtube.com/watch?v=E7ZNRLBE4Iw[/ame]

Rainbow Warrior Truck Racing team . A load of work to redo a lot of modifications to the engine.

As always communication is vital between the team and us to avoid problems. If you update parts on an engine most of the time it will only work if other engines parts are not changed and in this case 2 things were changed on the race engine resulting in smoke hi EMP and EGT 200Rpm less max torque so in general not a good performing engine but we worked things out before the first race and after the second start due to a red flag they hold second position but being the BTRA thing go full contact on the track so red flag again as to many when of the track and on the start grit the technical comity went a bit nervous as one of the rims had a small dent in it so they where taken out of the race.

During the remaining 4 racing I mange to optimise timing and fuel pressure up to a point that the commonrail fuel pump is @ it’s max delivery and still no smoke and 16AFR even hi up the RPM range so I’m happy. On a dry circuit we still 2 seconds slower that Nr 1 truck mainly due to better traction but yes these are factory build FIA race trucks.

Engine mid en top end power is there but need to start working on anti turbo lag by adding post injections but this can be a tricky thing to spool the turbo when power request is zero.

Same thing can be done by left feet breaking while controlling boost/engine power with the accelerator peddle but the driver was unable to do this on the first bent after start as he goes in to aggressive in to the turn unable to left feet break and build boost on the downhill side of the bent lacking boost and power on the uphill part after so that’s where we lost time.

Last race was all wet on the track holding second place until the last round. Power lost after the first bent was solved as going in slower in to the bent able to apply engine power sooner building full boost and torque pulling as hard a the factor spec engines.

Also nice to hear the commentator say Scania leader of the MAN race pack.LOL

To bad as in the last round the driver made a small mistake with breaking losing 3 places ending up in 5 position but well this is close racing.

[ame="http://www.youtube.com/watch?v=E7ZNRLBE4Iw"]http://www.youtube.com/watch?v=E7ZNRLBE4Iw[/ame]

Last edited:

Volvo D13 engine Blackjack racing.

This OE relative low budged engine concept really works well for the B class BTRA.

A standard D13 Volvo engine and a Scania V8 OE Garrett turbocharger of a D16 engine makes great power and no smoke.

We finally word things out with the injector control as before the injectors did not last more than 5 races but no it’s fine making even more power.

The result was 3x first place 1x second place and one time 4 place as they had a family affair battling it out for first and second place as his brother try to push him of the track and they ending up stuck with each other in the middle of the track.:stab:

Also take in mind that the start is with a reversed grid so first place last race end up on the last start position on the end of the start grid so you have to overtake them all to get first place.

On the end of all races we end up with the most points on race results getting the trophy for best result on the first race weekend. Blackjack racing team is considering also running the rest of the championship if there budged allows it.

[ame="http://www.youtube.com/watch?v=6o_XmEfEp6A"]http://www.youtube.com/watch?v=6o_XmEfEp6A[/ame]

[ame="http://www.youtube.com/watch?v=Z3U6YmTsbOw"]http://www.youtube.com/watch?v=Z3U6YmTsbOw[/ame]

[ame="http://www.youtube.com/watch?v=CL7V6HX1Mig"]http://www.youtube.com/watch?v=CL7V6HX1Mig[/ame]

[ame="http://www.youtube.com/watch?v=rr77RgZP9bU"]http://www.youtube.com/watch?v=rr77RgZP9bU[/ame]

[ame="http://www.youtube.com/watch?v=vE6nP_jXz8c"]http://www.youtube.com/watch?v=vE6nP_jXz8c[/ame]

This OE relative low budged engine concept really works well for the B class BTRA.

A standard D13 Volvo engine and a Scania V8 OE Garrett turbocharger of a D16 engine makes great power and no smoke.

We finally word things out with the injector control as before the injectors did not last more than 5 races but no it’s fine making even more power.

The result was 3x first place 1x second place and one time 4 place as they had a family affair battling it out for first and second place as his brother try to push him of the track and they ending up stuck with each other in the middle of the track.:stab:

Also take in mind that the start is with a reversed grid so first place last race end up on the last start position on the end of the start grid so you have to overtake them all to get first place.

On the end of all races we end up with the most points on race results getting the trophy for best result on the first race weekend. Blackjack racing team is considering also running the rest of the championship if there budged allows it.

[ame="http://www.youtube.com/watch?v=6o_XmEfEp6A"]http://www.youtube.com/watch?v=6o_XmEfEp6A[/ame]

[ame="http://www.youtube.com/watch?v=Z3U6YmTsbOw"]http://www.youtube.com/watch?v=Z3U6YmTsbOw[/ame]

[ame="http://www.youtube.com/watch?v=CL7V6HX1Mig"]http://www.youtube.com/watch?v=CL7V6HX1Mig[/ame]

[ame="http://www.youtube.com/watch?v=rr77RgZP9bU"]http://www.youtube.com/watch?v=rr77RgZP9bU[/ame]

[ame="http://www.youtube.com/watch?v=vE6nP_jXz8c"]http://www.youtube.com/watch?v=vE6nP_jXz8c[/ame]

Last edited:

This is how it looks like if you think that you can pass the 100 mile hour peed limit, easy overtaking where others stick to the max speed limit @ 6.40 min on the youtube.:badidea:

Disqualification as speed is recorded by GPS and 1 Km over is for more than 2 seconds is game over.

[ame="http://www.youtube.com/watch?v=enGk8vg1Tt8"]http://www.youtube.com/watch?v=enGk8vg1Tt8[/ame]

Disqualification as speed is recorded by GPS and 1 Km over is for more than 2 seconds is game over.

[ame="http://www.youtube.com/watch?v=enGk8vg1Tt8"]http://www.youtube.com/watch?v=enGk8vg1Tt8[/ame]

Leiffi

New member

- Joined

- Jan 31, 2013

- Messages

- 1,381

This is how it looks like if you think that you can pass the 100 mile hour peed limit, easy overtaking where others stick to the max speed limit @ 6.40 min on the youtube.:badidea:

Disqualification as speed is recorded by GPS and 1 Km over is for more than 2 seconds is game over.

http://www.youtube.com/watch?v=enGk8vg1Tt8

Must have been too excited of Cummins power from Finland.

Must have been too excited of Cummins power from Finland.

Yes we all like the taste of diesel fumes in the morning. :Throwup: M11 N14 NT855 even. Smelly things these Cummins engines and a load of trouble to maintain them. The whole B division trucks BTRA runs them but lack the performance so maybe you need to go over and help them for free. :hehe: Any thing better than posting silly commends mate. Meanwhile smart team start using the Volvo D13 engines.

Had a go with this 2.5L 5 cylinder VW diesel engine. Had to make some modifications to the software for the boost controller as this engine is able to build massive torque @ low RPM it will need boost instantaneous between gear shifts so I was able to bring the pressure drop down to 27Kpa and this engine is running a electronic activated VNT and BOV as well and to my surprise the BOV helps as well by keeping the compressor out of surge.

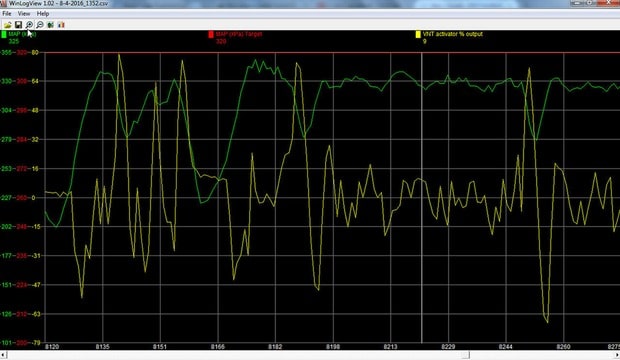

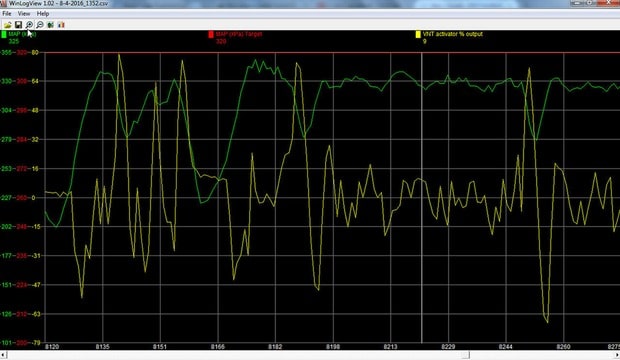

The VNT activator has a position fly back to the ECU and is not spring charged so the ECU only controls the activator motor until it on the desired position and ones it is there the VNT activator PWM % goes to zero. So what your seeing below in yellow is the VNT vanes on the turbine being closed during a gear shift a and short after the VNT vanes go back to a position to maintain the boost target.

Still smokes bit a as the charge air cooler is not up to the job reading intake air temp over 118 degrees centigrade, no good getting a bit more air mass in.:doh:

[ame="http://www.youtube.com/watch?v=gEsihRRdTKw"]http://www.youtube.com/watch?v=gEsihRRdTKw[/ame]

The VNT activator has a position fly back to the ECU and is not spring charged so the ECU only controls the activator motor until it on the desired position and ones it is there the VNT activator PWM % goes to zero. So what your seeing below in yellow is the VNT vanes on the turbine being closed during a gear shift a and short after the VNT vanes go back to a position to maintain the boost target.

Still smokes bit a as the charge air cooler is not up to the job reading intake air temp over 118 degrees centigrade, no good getting a bit more air mass in.:doh:

[ame="http://www.youtube.com/watch?v=gEsihRRdTKw"]http://www.youtube.com/watch?v=gEsihRRdTKw[/ame]

http://www.adaptronic.com.au/forum/index.php?topic=6558.0

Proud that we have been able to achieve this.

We know what motor sports is about and we also know how most diesel engines work and then it’s just a sumation on options what you have to offer a professional truck racing teams.

Over the years we have prove that we can build a good and stable engine management which I now know that we can surpass many standard ECU system on a number of points and this will pay it self back in gains on engine performance.

Last week they tested the truck on the cirquit which the 2016 spec 63mm inlet restriction instead of 65mm used in previous years . In exchange for the decrease in engine power the team can take off 300Kg of the minimum weight of the semi truck ending up with a bout the same Hp to weight ratio. The max Torque: >5500 Nm remians the same but as you can understand ones the RPM of the engine goes up it will need more air and than the 63mm inlet retriction on front of the turbo compressor will setrickt airflow/power output.

Proud that we have been able to achieve this.

We know what motor sports is about and we also know how most diesel engines work and then it’s just a sumation on options what you have to offer a professional truck racing teams.

Over the years we have prove that we can build a good and stable engine management which I now know that we can surpass many standard ECU system on a number of points and this will pay it self back in gains on engine performance.

Last week they tested the truck on the cirquit which the 2016 spec 63mm inlet restriction instead of 65mm used in previous years . In exchange for the decrease in engine power the team can take off 300Kg of the minimum weight of the semi truck ending up with a bout the same Hp to weight ratio. The max Torque: >5500 Nm remians the same but as you can understand ones the RPM of the engine goes up it will need more air and than the 63mm inlet retriction on front of the turbo compressor will setrickt airflow/power output.

Fast stage time for the first two trucks during the 2nd special stage of the Libya Rally .

Jos Smink with the Factory Cummins/Ginaf truck in a 4th place overall at 31.21 minutes behind Jacky Loomans with the Hilux Overdrive with a 5th place overall Schoones Dakar with Euro6 Daf and exactly 5 minutes behind Jos Smink .

Martin van den Brink with the MKR Renault truck lay long been third in the truck class on a 1 hour time penalty he finish on a 16 place overall and 6th in the trucks.

Jos Smink with the Factory Cummins/Ginaf truck in a 4th place overall at 31.21 minutes behind Jacky Loomans with the Hilux Overdrive with a 5th place overall Schoones Dakar with Euro6 Daf and exactly 5 minutes behind Jos Smink .

Martin van den Brink with the MKR Renault truck lay long been third in the truck class on a 1 hour time penalty he finish on a 16 place overall and 6th in the trucks.