Yes, XPI is nice, but can you ever beat Sigma pumps with your modern technology ?

I dont know why but no one gets any power out of Euro3 cams, only smoke and high EGT.

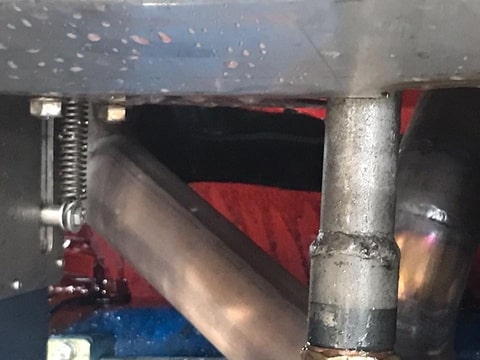

Yes, XPI is nice, but can you ever beat Sigma pumps with your modern technology ? Well time will tell. LOL. For now we got some power almost no smoke and a pistonring seal problem on the new engine so we got some work to do.

I dont know why but no one gets any power out of Euro3 cams, only smoke and high EGT. Well maybe unable to master the fuel system than. So many from Scandinavia asked us what we are using and doing but the simple fact is we can build stuff but not a lot are willing to pay for it. Fact is to make good power no smoke and low EGT you need to chance cams as you need to get the fuel in a lot faster. Same thing is we can build a 30% bigger injector but for a daily use truck it will not run clean on low end power having low boost as the OE cams do not provide the plunger travel speed to run clean. We also know how to get a load more fuel out of a OE injector but this will only happen for the most part above 2100Rpm.

So there are plenty of options.

[ame="http://www.youtube.com/watch?v=5uAKJgqt4LI"]MVJ2 Boekel Demo nieuwe commonrail XPI motor - YouTube[/ame]

Last edited: