A friend of mine and member on here ( stoker) just bought a 91 I/c first Gen that will be a party time puller eventually. He will be doing the body work and several of us will be doing the motor work. I've been reading and watching instructional videos for the past week on pump tuning and I have a few questions. 1. Do you adjust the " power screw" while the trucks running. 2. Rotate fuel pin or buy aftermarket pin. 3. Is preboost fuel adjusted with starwheel or " smoke screw ". This is just to have a little fun pulling on the weekends whether its competitive or not. Sorry for the long post and the newborn questions I just don't have any experience with a be. Thanks in advance

1. Do you adjust the " power screw" while the trucks running?

- It can be, but you'll find fuel shut-off solenoid can be easily bumped with your wrench and the resulting electrical short can be a fairly big PITA. Realistically though, removing the jamb-nut / locking-sleeve boogers the threads such that just dicking with the fuel-screw is a PITA. Most won't remove the screw and fix all that crap to start with. Just plan on turning things a half-turn at a time as you dial everything in.

2. Rotate fuel pin or buy aftermarket pin?

- Rotating the fuel-pin means nothing. You'd do well to pull the fuel-pin and look at the conical shaped ramp so as to understand its profile and what position provides the most fuel. An aftermarket fuel-pin can allow more fuel. Be careful in selecting an aftermarket pin as most with an aggressive ramp often don't "fit" with the insufficient air provided by the existing turbo (meaning they're a smoky turd and NOT quick out of the hole). ->

Lean is mean.

The thing to remember is, the AFC system in general is more suited to providing the ideal fuel ratio in a part-throttle situation. If you're gonna be pulling, You're most likely gonna be doing it at WOT . . . which isn't where the AFC is primarily intended to function.

3. Is preboost fuel adjusted with starwheel or " smoke screw "?

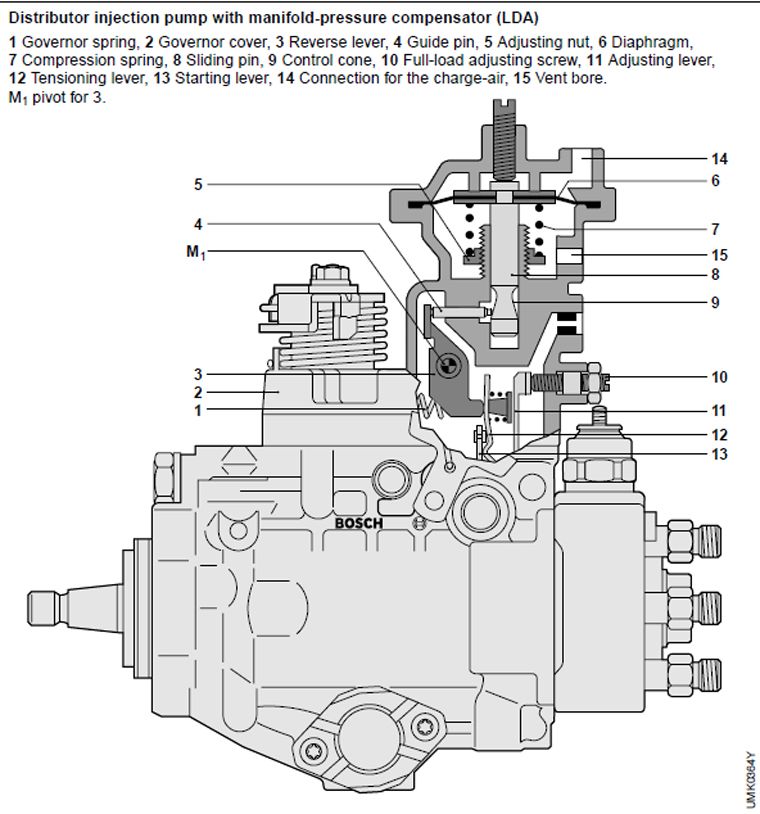

- The Smoke-Screw. With NO boost, the smoke-screw sets the minimum position of the Fuel-pin. That where the pin rests, by way of the spring pressure.

- The Star-Wheel is what establishes the rate of rise, of fuel to the increasing boost (typically in a part-throttle situation.

Keep in mind, the AFC system (including the Fuel-Pin, Star-Wheel (and associated spring), Smoke-Screw, etc) all work together to define the ideal fuel/air ratio in a part-throttle application.

(Note proper component names)

** The above is nothing more than my opinion based on my experience with my mess and that that I've learned from reading technical manuals and listening to actual professionals and tinkering on a handful of old pumps. I am not an arrogant ass who snows a bunch of folks on these here internets.

Season to taste / your mileage may vary.