You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

12 Valve Fuel System

- Thread starter 97' CTD

- Start date

Bobcat698

Pure Diesel Power

- Joined

- Apr 24, 2006

- Messages

- 2,229

Smokem said:Neither of you ran the -10AN banjo bolt from BAT then I take it?

"BAT"???? Sorry I'm clueless...

joefarmer

MR. Supreme Overlord

- Joined

- Jul 31, 2006

- Messages

- 6,137

Silly question- the truck in my sig made 590 on nitrous with a stock liftpump and 500psi bottle pressure. Is that a fluke and does that indicate my stock liftpump is abnormally good?

I'm piecing together a complete fuel system including moderately tweaked 180 ppump, boost referenced regulator, filters on the frame rail and an aftermarket liftpump. I'm having trouble wrapping my head around the regulator. I would think the regulator inlet gets plumbed to the return outlet of the ppump, the outlet of the regulator gets plumbed into the return to the fuel tank. I'm confused where the regulator bypass gets plumbed into. Help?

brnaodn.

I'm piecing together a complete fuel system including moderately tweaked 180 ppump, boost referenced regulator, filters on the frame rail and an aftermarket liftpump. I'm having trouble wrapping my head around the regulator. I would think the regulator inlet gets plumbed to the return outlet of the ppump, the outlet of the regulator gets plumbed into the return to the fuel tank. I'm confused where the regulator bypass gets plumbed into. Help?

brnaodn.

Signal 73

#2 is #1

- Joined

- Jul 30, 2006

- Messages

- 1,124

Decided to go with the M18 from them instead, didnt feel like messing with the helicoil. Im sure thats another great way to do it. Return line does use a banjo from them however.Smokem said:Neither of you ran the -10AN banjo bolt from BAT then I take it?

Signal 73

#2 is #1

- Joined

- Jul 30, 2006

- Messages

- 1,124

http://www.batinc.net/plumbing.htm has difficult to find -an to metric fittings. there out of florida.Bobcat698 said:"BAT"???? Sorry I'm clueless...

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,072

joefarmer said:Silly question- the truck in my sig made 590 on nitrous with a stock liftpump and 500psi bottle pressure. Is that a fluke and does that indicate my stock liftpump is abnormally good?

I'm piecing together a complete fuel system including moderately tweaked 180 ppump, boost referenced regulator, filters on the frame rail and an aftermarket liftpump. I'm having trouble wrapping my head around the regulator. I would think the regulator inlet gets plumbed to the return outlet of the ppump, the outlet of the regulator gets plumbed into the return to the fuel tank. I'm confused where the regulator bypass gets plumbed into. Help?

brnaodn.

Junk the OF valve...you'll hook the "inlet" of the regulator to there, and use the "return" port to go back to the tank. At least that's how it works in my head!

I'm planning on splitting the -10A/N line from the pump, and using both feed ports on the pump, then return through a boost reference regulator (which the boost reference will be run through a valet switch, so the pressure is constant, except when I need the extra)

I got most of my ideas from Jim Fulmer!

Chris

Signal 73

#2 is #1

- Joined

- Jul 30, 2006

- Messages

- 1,124

I just capped mine off. Dont think you really need to bother referencing boost either IMHO. T-ed the injector return line into the fuel return line after the regulator also.joefarmer said:. I'm confused where the regulator bypass gets plumbed into. Help?

brnaodn.

Twisted Shifter

New member

- Joined

- Jun 28, 2006

- Messages

- 2,323

When I made 600HP @ Suncoast in January, I was on stock lift pump with a PDR Stupid pump?

Jim Fulmer

New member

- Joined

- May 6, 2006

- Messages

- 5,013

I ran my 10 AN line to the Y block I was talking about then ran one 6AN line to the tapped banjo bolt so I can still run my stock lift pump then ran the other to the front inlet. I had ordered a 6,8 and 10 inlet fitting for the front but only got the 6 in so that is what I am running now. I'm sure a 8 or a 10 there would be better.

My regulator is mounted way over in the back corner drivers side and yes ti taps into the stock return line as does the injector return.

I'm currently ditching the stock filter setup and going to a 2 micron to try and keep from continuing to tearing up injectors due to trash. This was sugjested to me along time ago by Brady Willams and I didn't do it but after tearing up 6 injectors in two different sets I learned. I can now clean my own stuff and pop check it in the garage cause I bought the stuff to do it.

Jim

My regulator is mounted way over in the back corner drivers side and yes ti taps into the stock return line as does the injector return.

I'm currently ditching the stock filter setup and going to a 2 micron to try and keep from continuing to tearing up injectors due to trash. This was sugjested to me along time ago by Brady Willams and I didn't do it but after tearing up 6 injectors in two different sets I learned. I can now clean my own stuff and pop check it in the garage cause I bought the stuff to do it.

Jim

Crawler

Press the BIG RED button.

- Joined

- Apr 30, 2006

- Messages

- 837

Jim Fulmer said:I would have to say Haisley's has the best/cheapest stand alone system out there. I ran it for 4 years before I slowly deleted/updated it to the current setup. Way back when I used it and was at 600 hp or so I could still maintain 35-40 psi at WOT.

Jim

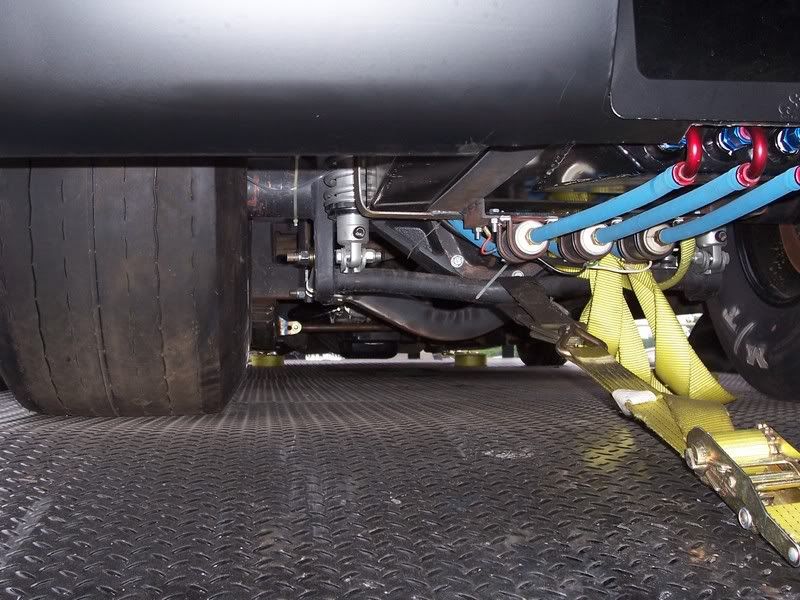

I go a bit crazy/overboard at times. But here is my fuel pump setup.

I use the pump that Haisley uses in there aux setup. Just happen to have a couple of spares mounted with it. :evil :evil :evil

~Wes~

Signal 73

#2 is #1

- Joined

- Jul 30, 2006

- Messages

- 1,124

thats sweet:rockwoot: are those like walbro's? look similar.

Jim fulmer, can you talk a little more about your injectors getting wrecked? maybe OT but its fuel sys related, sorta. 10 micron not good enough to stop injector wrecking debris, or does stuff get in there when your swapping stuff out?

Jim fulmer, can you talk a little more about your injectors getting wrecked? maybe OT but its fuel sys related, sorta. 10 micron not good enough to stop injector wrecking debris, or does stuff get in there when your swapping stuff out?

sniperonhigh

12v Rookie

- Joined

- Jun 12, 2007

- Messages

- 107

Check out http://www.vulcanperformance.com/servlet/the-5%29-Fittings-dsh-Components-cln-Metric-Adaptors/Categories these folks for some good fittings and such. I have an SX pump that is fed by an airdog that I use with a 5 micron filter, do these engines need 2u or is 5u enough?? A regulated return system is a proven system on other engines, the regulator will take the place of the overflow valve on a p-pump. As for pressure I don't think excessive inlet pressure to the delivery valves will help, it doesn't work that way. No need for boost pressure reference, seems like it just needs a good constant supply of fuel without any pressure loss.

Jim Fulmer

New member

- Joined

- May 6, 2006

- Messages

- 5,013

Jim Fulmer, can you talk a little more about your injectors getting wrecked? maybe OT but its fuel sys related, sorta. 10 micron not good enough to stop injector wrecking debris, or does stuff get in there when your swapping stuff out?

I sent my 370's in while I was gone on the road and Brady called me and said 4 of them would not pop right so he fixed the other two and replaced the 4. What I see now on my end now that I have a pop tester is you can clean an injector up externally with brake cleaner and a brush, take it apart and run cleaner through it, blow everything out, drop the nozzle into a ultra sonic cleaner then lube and put them back together. Install on the pop test

er and pull say 3000 psi and hold it and they will sit there and drip.......this causes idle smoke, or excess of. When it does pop it doesn't viberate the bench and fog fuel, it shoots it in more of a stream........not atomizing.

The crap is coming from the fuel as it's not clean enough nor is the filter fine enough, this should cure that issue.

Jim

joefarmer

MR. Supreme Overlord

- Joined

- Jul 31, 2006

- Messages

- 6,137

Signal 73 said:I just capped mine off. Dont think you really need to bother referencing boost either IMHO. T-ed the injector return line into the fuel return line after the regulator also.

Cool! I had everything figured out but the bypass. I figured you had to run that one too. :doh:

Signature600 said:Junk the OF valve...you'll hook the "inlet" of the regulator to there, and use the "return" port to go back to the tank. At least that's how it works in my head!

Sorry, that was in my head but I forgot to mention the OF will meet Mr Trashcan. I know we'd talked about it before, but I couldn't remember where the bypass went. I still want a filter & water separator setup like Chuck put on his for $45.

I just had an idea... I think I'll run 2x walbro's w/ checkvalves and two pickups in the tank. One tied to the ignition and the other tied to the nitrous system's arm switch. Then I won't forget to switch it on!

brandon.

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,072

joefarmer said:I just had an idea... I think I'll run 2x walbro's w/ checkvalves and two pickups in the tank. One tied to the ignition and the other tied to the nitrous system's arm switch. Then I won't forget to switch it on!

brandon.

That's a heck of a good idea...I might do something like that, only tied to the valet switch. I'll get the part numbers for the filter setup!

One problem...how do you run 2 pumps with one filter setup?

Chris

joefarmer

MR. Supreme Overlord

- Joined

- Jul 31, 2006

- Messages

- 6,137

That's what the check valve ensures- it doesn't allow backwards flow through pump that's off.

two 40 micron filter socks -> two pickups -> two pumps -> two check valves -> 2u filter/water separator -> ppump -> regulator -> return line.

bnraond.

two 40 micron filter socks -> two pickups -> two pumps -> two check valves -> 2u filter/water separator -> ppump -> regulator -> return line.

bnraond.