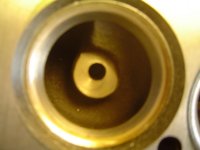

yes, i did cc them. they are 10cc's. even thought the surface gets covered with carbon, it still will reflect the heat energy. the heat energy will conduct through the carbon then be reflected by the polished surface underneath. there are companies that coat pistons and such to reflect heat. they get coated with carbon too. yet they still have proven that the heat gets reflected, even through the carbon, same concept here...

That's good on the measurements. I wouldn't worry at all about them being slightly uneven (not perfectly smooth) then.

On the heat transfer stuff, my train of thought is there are three ways to transfer heat; conduction, convection, and radiation. Conduction is physical contact between solids and will always transfer heat the fastest out of the three ways. Convection is the transfer via a liquid/gas. This is dependent on flow rate and wall roughness typically, and buoyancy is a factor (the whole heat rises thing, but not as much with quick events). Then there is Radiation, which would be the transfer of heat via emissivity (~light rays).

Usually polishing (strictly talking heat, nor polishing runners, or connecting rods) is done to reflect radiation since radiation is light based, the more reflective the surface, the less heat is absorbed. This is also why laser cutting shiny stuff is a pain. Convectively, the rougher the surface, the more heat transfer because the rough surface breaks up the boundary layer near the wall and slightly increases the surface area (think micro-fins). So I’d think it would help in that aspect.

There’s no conduction in cylinder regarding the ignition. My thoughts being; the polished surface gets coated by a rougher, non-reflective layer of carbon, and now absorbs some heat. Then conducts it through the layer of polished surface as if it weren’t there. The only advantage I could see at this point would be that you’d still have a smoother surface than a standard carbon coated head, and convectivity would be down.

So… after thinking through it all. I can see an advantage. I’m just not sure if you’d be able to measure a difference in an A to B test.

Also, sorry to get off topic on your for sale thread. I like seeing people trying different things and discussing them.