3rd Gen Steed Speed Manifold Test

Task:

To complete a same day back to back comparison of a stock 3rd Gen 5.9 Cummins manifold vs. a Steed Speed engineered bolt on replacement manifold.

Test Date: 11/8/12

Test Truck: 2005 Dodge 2500 5.9L Common Rail Diesel

Modifications:

-Bosch 100HP Motorsport Injector Nozzles

-Fleece HE351cw 63mm Billet Holset Cheetah Turbo

-Motorsport Diesel Stroker CP3

-Smarty SO-6 Tuning (Lvl 7)

Dyno: DC Chassis Dyno, Brownsburg, IN

-Dyno Jet 224XLC

-Indoor Climate Controlled

Dyno Runs:

Each dyno pull was started at 1300 RPM and ran until 1600 Degrees of Exhaust Gas Temperature.

Each pull would be replicated inside of these two parameters, in order to insure the same start and finish of each run.

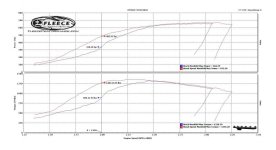

Results: Sampled at Maximum output & at 2000 RPM

Base Line with stock Manifold Rating at 2000 RPM

-Max HP 656.79 @ 2950 RPM -HP 338.58

-Max TQ 1316.79 @ 2450 RPM -TQ 889.22

Steed Speed Manifold Rating at 2000 RPM

-Max HP 672.36 @ 3100 RPM -HP 482.82

-Max TQ 1355.20 @ 2300 RPM -TQ 1267.77

Overview:

The test truck was base lined at 11:30 AM Thursday November 8, 2012, with the modifications listed above and a stock 5.9 Cummins exhaust manifold. After installing the Steed Speed manifold the test truck was dynoed again at 4:30 PM November 8, 2012. A brief look at the results shows a decent gain in maximum output; 16 RWHP and 38 RWTQ. However a closer look shows a much broader power curve with peak torque coming in 150 RPM sooner, and peak horsepower carrying out another 150 RPM.

At 2000 RPMs the gains were much more significant, with an increase of 143.24 RWHP and 378.55 RWTQ as seen in the graph below. With the addition of the Steed Speed manifold, without any tuning changes, the truck was capable of pulling a more aggressive load profile on the dyno, whereas with the stock manifold the truck could not. Furthermore because of the apparent increase in flow, the truck was able to pull another 250 RPM before hitting our stopping point of 1600 Degrees, also illustrated in the graph.

On the street, the increase in low end torque and response was immediately noticed, as well as the trucks new distinct sound. EGT’s were down 100-300 degrees in normal “day to day” style driving. Overall the Steed Speed clearly did its job of increasing flow, and making more torque, evident in the graph below. More so the Steed Speed Manifold also reduced Exhaust Gas Temperature

These results are accurate for this particular truck, with the specified modifications installed. Different trucks with different modifications may have different results.

Interesting info....

Caleb

Task:

To complete a same day back to back comparison of a stock 3rd Gen 5.9 Cummins manifold vs. a Steed Speed engineered bolt on replacement manifold.

Test Date: 11/8/12

Test Truck: 2005 Dodge 2500 5.9L Common Rail Diesel

Modifications:

-Bosch 100HP Motorsport Injector Nozzles

-Fleece HE351cw 63mm Billet Holset Cheetah Turbo

-Motorsport Diesel Stroker CP3

-Smarty SO-6 Tuning (Lvl 7)

Dyno: DC Chassis Dyno, Brownsburg, IN

-Dyno Jet 224XLC

-Indoor Climate Controlled

Dyno Runs:

Each dyno pull was started at 1300 RPM and ran until 1600 Degrees of Exhaust Gas Temperature.

Each pull would be replicated inside of these two parameters, in order to insure the same start and finish of each run.

Results: Sampled at Maximum output & at 2000 RPM

Base Line with stock Manifold Rating at 2000 RPM

-Max HP 656.79 @ 2950 RPM -HP 338.58

-Max TQ 1316.79 @ 2450 RPM -TQ 889.22

Steed Speed Manifold Rating at 2000 RPM

-Max HP 672.36 @ 3100 RPM -HP 482.82

-Max TQ 1355.20 @ 2300 RPM -TQ 1267.77

Overview:

The test truck was base lined at 11:30 AM Thursday November 8, 2012, with the modifications listed above and a stock 5.9 Cummins exhaust manifold. After installing the Steed Speed manifold the test truck was dynoed again at 4:30 PM November 8, 2012. A brief look at the results shows a decent gain in maximum output; 16 RWHP and 38 RWTQ. However a closer look shows a much broader power curve with peak torque coming in 150 RPM sooner, and peak horsepower carrying out another 150 RPM.

At 2000 RPMs the gains were much more significant, with an increase of 143.24 RWHP and 378.55 RWTQ as seen in the graph below. With the addition of the Steed Speed manifold, without any tuning changes, the truck was capable of pulling a more aggressive load profile on the dyno, whereas with the stock manifold the truck could not. Furthermore because of the apparent increase in flow, the truck was able to pull another 250 RPM before hitting our stopping point of 1600 Degrees, also illustrated in the graph.

On the street, the increase in low end torque and response was immediately noticed, as well as the trucks new distinct sound. EGT’s were down 100-300 degrees in normal “day to day” style driving. Overall the Steed Speed clearly did its job of increasing flow, and making more torque, evident in the graph below. More so the Steed Speed Manifold also reduced Exhaust Gas Temperature

These results are accurate for this particular truck, with the specified modifications installed. Different trucks with different modifications may have different results.

Interesting info....

Caleb