I also am looking into the HE351ve off the 6.7 motor. If you figure out a creative way to control the variable vane width let me know. Currently, I'm thinking about trying to let drive pressure push the vane wider with a mild spring to control opening and an adjustable bolt to control maximum opening and maximum closure. My only fear is that as soot builds up, i will have a tuning nightmare as more and more drive pressure would be required to push the vane open. Thoughts?

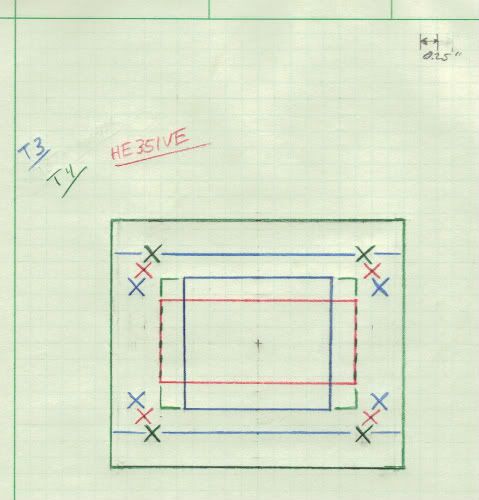

I also noticed that the outlet on the 6.7 turbine housing is smaller than the 5.9 He351cw housing. If a true HX40 vband is 4 and 1/16", then the 6.7 outlet is HX40 style instead of 5.9 He351cw 4 and 3/16".

I'm sure you're aware that the 6.7 turbine inlet flange is larger as well. I don't have specs for a t-4 flange but my best guess is that the 6.7 turbine inlet is the same size.

On a positive note, the 6.7 turbo has a 70.5mm exhaust wheel with a 66mm exducer, add in the variable housing and I think the HE351ve will be a mean turbo. Fast spooling and air for 550 HP. The compressor side mic'd out to 60.1mm inducer, 85-88mm exducer depending on where you measure.