You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advantages of higher PSI for Water Injection?

- Thread starter Begle1

- Start date

Begle1

Active member

- Joined

- Nov 18, 2007

- Messages

- 4,178

That's the only reason I could think of.

The big dogs that run water injection seem to all be in the 500-600 PSI range.

Somehow I ended up flirting with the idea of replacing my air conditioner with a hydraulic pump and injecting water cut with cutting fluid at 1000 PSI through nitrous solenoids.

Think it'd be worth it? Will it work?

The big dogs that run water injection seem to all be in the 500-600 PSI range.

Somehow I ended up flirting with the idea of replacing my air conditioner with a hydraulic pump and injecting water cut with cutting fluid at 1000 PSI through nitrous solenoids.

Think it'd be worth it? Will it work?

jfaulkner

Douche Hunter

- Joined

- Sep 24, 2007

- Messages

- 5,864

The belt driven hydraulic pump is what most mod trucks run but I don't know how the pump will like deadheading into those solenoids when they're shut. The mod trucks use a Simpson valve that lets the water circulate until the boost redirects it to the nozzles. You can use a 12v hydraulic pump. There are a few trucks using those for water injection and you can turn the pump on with a pressure switch set at the boost level you wish, or wire it to a manual switch. You can also add nozzles and solenoids as you need them but the pump isn't running when it isn't needed.That's the only reason I could think of.

The big dogs that run water injection seem to all be in the 500-600 PSI range.

Somehow I ended up flirting with the idea of replacing my air conditioner with a hydraulic pump and injecting water cut with cutting fluid at 1000 PSI through nitrous solenoids.

Think it'd be worth it? Will it work?

Here is the pump some people use.

Here is the same pump but with a smaller tank in case you choose to add your own.

Begle1

Active member

- Joined

- Nov 18, 2007

- Messages

- 4,178

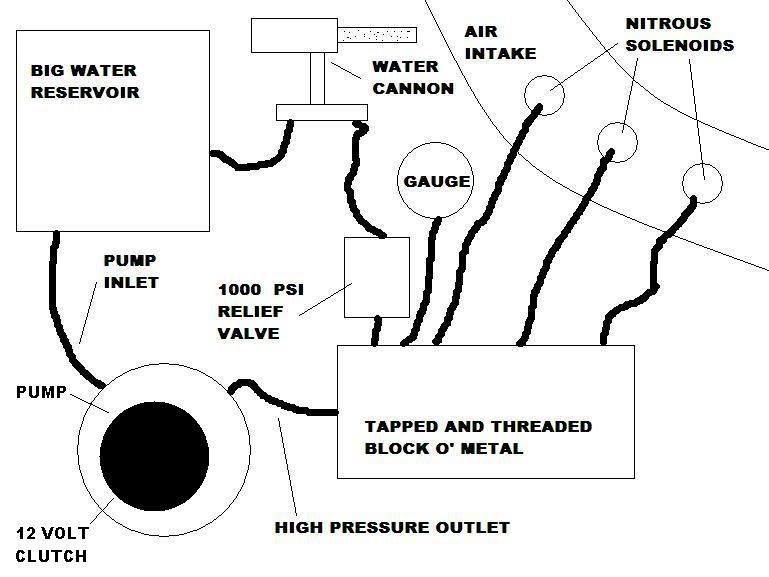

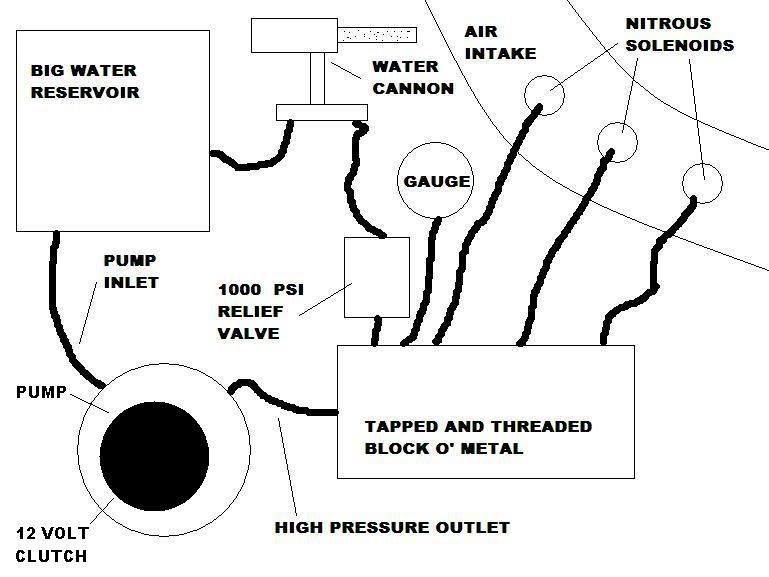

Well, the current idea is as below...

The pump is a snowplow pump that I got off eBay for $.99, and I'm going to try to mount it onto clutch. I can get a lawnmower clutch off eBay for $.99, I don't know how much horsepower it should be rated for... Gotta use a clutch to save the engine in case of solenoid failure, and prevent the parasitic drag of the pump when I'm cruising.

My understanding of hydraulics is minimal, but I was planning on running a relief valve to keep the pressure at the solenoids at an acceptable level.

So I flip my Mad-Max style clutch switch at the staging line, and that pressurizes the system. Then I turn my solenoid controller on, and I'm ready to rock...

Anybody with a fluid dynamics background know how much PSI a 3000 PSI hydraulic pump will put out if it's pumping water?

Would cutting the water with cutting fluid be sufficient to lubricate and prevent rust in the pump?

The pump is a snowplow pump that I got off eBay for $.99, and I'm going to try to mount it onto clutch. I can get a lawnmower clutch off eBay for $.99, I don't know how much horsepower it should be rated for... Gotta use a clutch to save the engine in case of solenoid failure, and prevent the parasitic drag of the pump when I'm cruising.

My understanding of hydraulics is minimal, but I was planning on running a relief valve to keep the pressure at the solenoids at an acceptable level.

So I flip my Mad-Max style clutch switch at the staging line, and that pressurizes the system. Then I turn my solenoid controller on, and I'm ready to rock...

Anybody with a fluid dynamics background know how much PSI a 3000 PSI hydraulic pump will put out if it's pumping water?

Would cutting the water with cutting fluid be sufficient to lubricate and prevent rust in the pump?

-----------------------------------------------------------What is (would be) the advantage in running ~1000 PSI-500 PSI water injection instead of the 150 or 220 PSI pumps that most designated "water injection" systems come with?

Begle1:

I can tell you that I have run both the older "Snow Water Injection System"

and now "Scheids Water Injection System" on my 1996 Dodge CTD and the difference is pretty darn amazing. Don't get me wrong, when I was around 600-650 H.P. the Snow System worked very well with the two (2) 625ml nozzles, but when I got up to the H.P. level I am at now, it would not keep all my cylinders cool. My Snow System had a 200psi Pump and the Scheid pump is rated at 500psi.

The Snow System with the two (2) nozzles in the air horn would keep cylinders #2,3,and 4 cool on WOT runs, but cylinders #1,5 and 6 were getting too hot. I saw a drop in water pressure also. So, Scheid installed one of their earlier systems for me and I now have five (5) nozzles machined directly into the cylinder head much like a "wet" nitrous system on a gas car.

This Scheid Water System has worked great for me. Even on WOT runs in hot, humid weather I keep my EGT's around 1350-1400 at all times.

I think you should be in good shape going with the system you have. Hope this helps you some. Good luck.

---------

John_P

B18B1LS1

New member

- Joined

- Aug 22, 2006

- Messages

- 1,429

I'm assuming 2,3,and 4 were good because the water was introduced to them first. And the farthest ones were lacking water. Does that mean any system no matter the pressure is going to "starve" the outer cylinders? Unless of course its plumbed into the head like yours.

nwpadmax

Turbo Geek

- Joined

- Nov 22, 2006

- Messages

- 3,128

you want it to vaporize not just be driplets.

I've heard two different theories on that and have wondered which one is true-

1) don't vaporize, yet have fine enough droplets that they actually make it into the cylinder so that you don't displace air with steam. You don't get the latent heat of vaporization with this one - so it's more cooling in the combustion chamber itself.

2) vaporize in the intake tract and take advantage of the latent heat of vaporization to cool the charge air.

I can see where both approaches have their points, but I've never seen any decent data on nozzle size / flow rate / IAT / EGT etc. with matching dyno plots to demonstrate it.

But as with everything, the guys who go through the trouble to figure it out, ain't spilling it to the public, which is understandable.

JOHNBOY

ZF6 Sled Puller

- Joined

- Feb 1, 2007

- Messages

- 1,854

Good thread!

I have wondered about the theory behind hi pressure water was. With that 12v pump what do you use for nozzles? Right angle N2O nozzle?

As to expand on the placement of nozzles as JohnP talked about. What is the deal with spraying one stage into the comp wheel of the turbo? I have seen this done on tractors. Usually three stages. Two in the manifold and one into the turbo.

I have wondered about the theory behind hi pressure water was. With that 12v pump what do you use for nozzles? Right angle N2O nozzle?

As to expand on the placement of nozzles as JohnP talked about. What is the deal with spraying one stage into the comp wheel of the turbo? I have seen this done on tractors. Usually three stages. Two in the manifold and one into the turbo.

roachie

Taco Master

- Joined

- Nov 2, 2007

- Messages

- 11,133

I have wondered the same about my setup. My kit has two 150psi pumps in a cooling mist setup with the programable robot box thingy. My delima has been where to place the nozzles. Then I realized if I go twins, how will water be atomized properly if the boost is 90psi?

Ive be looking at 12v hyraulic pumps. They put out 1600psi, this need to be reduced to 600. Then how?

How yould you lube the pump?

Wich No2 nozzles do you use fuel or giggle gas?

My plan involved lots of relays and the same robot box to control it. Use one of the existing pumps to spray pre turbo and between the stages. Of course have the water come on in stages.

What are the effects of pre turbo water? Or damages

Like your digram, is the water cannon cab or bed mounted?

Ive be looking at 12v hyraulic pumps. They put out 1600psi, this need to be reduced to 600. Then how?

How yould you lube the pump?

Wich No2 nozzles do you use fuel or giggle gas?

My plan involved lots of relays and the same robot box to control it. Use one of the existing pumps to spray pre turbo and between the stages. Of course have the water come on in stages.

What are the effects of pre turbo water? Or damages

Like your digram, is the water cannon cab or bed mounted?

nwpadmax

Turbo Geek

- Joined

- Nov 22, 2006

- Messages

- 3,128

Well usually to reduce the pressure output of most pumps, you just make a return circuit to "bleed" the pressure back to the inlet side with some sort of needle valve / orifice / etc.

There are more sophisticated ways of doing it but you get the general idea.

Plus remember, you have to know pressure at whatever flow rate you're interested in. A pump that makes 1600 psi deadheaded will make considerably less as you head toward max flow. Pumps all have performance curves, you just have to go to the trouble of finding them.....or better yet, set the damn thing up and experiment.

There are more sophisticated ways of doing it but you get the general idea.

Plus remember, you have to know pressure at whatever flow rate you're interested in. A pump that makes 1600 psi deadheaded will make considerably less as you head toward max flow. Pumps all have performance curves, you just have to go to the trouble of finding them.....or better yet, set the damn thing up and experiment.

-----------------------------------------------------------------------I'm assuming 2,3,and 4 were good because the water was introduced to them first. And the farthest ones were lacking water. Does that mean any system no matter the pressure is going to "starve" the outer cylinders? Unless of course its plumbed into the head like yours.

B18B1LS1:

Yes, I agree with you that the heat problem in my engine on cylinders #1,5 and 6 were because the water amount and pressure were insufficient to keep the EGT's down. More nozzles on the 200psi pump made the "steady run pressure" worse. Now with Scheids big pump, ALL of my cylinder temperatures were pretty darn equal and adding more nozzles does not seem to "pull" that big pump down either. But, as you said, the way my nozzles are located is probably optimizing the water system too.

---------

John_P

-------------------------------------------------------------------I have wondered the same about my setup. My kit has two 150psi pumps in a cooling mist setup with the programable robot box thingy. My delima has been where to place the nozzles. Then I realized if I go twins, how will water be atomized properly if the boost is 90psi?

Ive be looking at 12v hyraulic pumps. They put out 1600psi, this need to be reduced to 600. Then how?

How yould you lube the pump?

Wich No2 nozzles do you use fuel or giggle gas?

My plan involved lots of relays and the same robot box to control it. Use one of the existing pumps to spray pre turbo and between the stages. Of course have the water come on in stages.

What are the effects of pre turbo water? Or damages?

Like your digram, is the water cannon cab or bed mounted?

roachie:

You asked about "how would you lube the pump?"

On my Scheid Water System, I use one of two (2) types of water pump lubricant and anti-rust additive. NAPA makes one brand called "Number 13" and "Bars Leak" another called; "Water Pump Lubricant and Anti-Rust Additive." They both have a white color to them and have a somewhat "oily

feel." I add one pint of these products to one gallon of distilled water for not only water pump lubrication, but also to keep rust from forming inside the cylinder head. They both work very well.

Hope this helps you some.

--------

John_P

Jim Fulmer

New member

- Joined

- May 6, 2006

- Messages

- 5,013

Now John!

You know us regular blue collar guys can't afford that high dollar stuff, and people like me will never know what the temp differences are between cylinders cause that takes a data logger.

My poor little workin' boy (2 pump-three nozzle) snow system seemed to work just fine at 870HP.....back in 05' but I currently just run one pump. I'll never the use the word envoy but I do like the high end water injection systems.

Joe Hellmann used a simular setup like mine but a high pressure (500 psi) pump and 3an lines with N2O nozzles!

Jim

You know us regular blue collar guys can't afford that high dollar stuff, and people like me will never know what the temp differences are between cylinders cause that takes a data logger.

My poor little workin' boy (2 pump-three nozzle) snow system seemed to work just fine at 870HP.....back in 05' but I currently just run one pump. I'll never the use the word envoy but I do like the high end water injection systems.

Joe Hellmann used a simular setup like mine but a high pressure (500 psi) pump and 3an lines with N2O nozzles!

Jim

----------------------------------------------------------------------Now John!

You know us regular blue collar guys can't afford that high dollar stuff, and people like me will never know what the temp differences are between cylinders cause that takes a data logger.

My poor little workin' boy (2 pump-three nozzle) snow system seemed to work just fine at 870HP.....back in 05' but I currently just run one pump. I'll never the use the word envoy but I do like the high end water injection systems.

Joe Hellmann used a simular setup like mine but a high pressure (500 psi) pump and 3an lines with N2O nozzles!

Jim

Jim:

Thanks for your input.

I know you and many of the other Members here have had good luck with the Snow System and in no way I am saying it is not a good system because I used one for a long time. I am very glad you were able to get adequate cooling from the Snow System on your high H.P. truck. I see in your post where you were also running three (3) nozzles versus the two (2) I had on my truck.

But, as I said in the earlier post I made, with the two (2) 625ml nozzles in the air horn and the 200psi RV Pump, it just was not able to keep my engine cool. We were using a CORSA Data System to monitor the cylinder temperatures to make sure everything was accurate. As you said, the systems are high, but I would add that mine was used and Scheid Diesel gave me a good deal on it. My pump is a little earlier model Scheid had. It is my understanding that the new pumps they sell now will put out between 800to 1000 psi.

I also know that many of the guys are "custom fitting" water systems for their trucks as you and the some of the other Members have mentioned and if that works then I am happy for you guys.

My biggest concern after seeing what I did with the Data Logger was I didn't want to ruin my engine and have to buy another motor because I didn't have adequate water to cool the motor. I'll be honest, until I actually saw the numbers I thought my Snow System would be able to do the job.

---------

John_P

CSM diesel

Engineer

- Joined

- Jun 1, 2007

- Messages

- 479

Time to break out the thermo book.....

Addressing a couple questions:

Water before the turbo is to cool the intake charge before compression, compressor erosion is a debated concern.

Either way that the water is injected (intake horn vs. directly in the head), the purpose is to cool.

This is done by taking energy away from the combustion process, too much thermo for me to explain fully right now.

Cheers.

Addressing a couple questions:

Water before the turbo is to cool the intake charge before compression, compressor erosion is a debated concern.

Either way that the water is injected (intake horn vs. directly in the head), the purpose is to cool.

This is done by taking energy away from the combustion process, too much thermo for me to explain fully right now.

Cheers.

Begle1

Active member

- Joined

- Nov 18, 2007

- Messages

- 4,178

For nozzles, I was planning on the 1000 PSI fogging nozzles from McMaster Carr.

$22.14 a piece, 450 degrees (too low?), 1/8" or 1/4", 5.1-84(!) GPH available.

I was thinking of running three right after the turbo in the intake horn, each one on it's designated nitrous solenoid... That way I could vary which ones are running and have 7~or~so stages.

I don't know anything about hydraulic systems, so I don't know what kind of regulator would be my best bet.

I was thinking something like this.

$22.14 a piece, 450 degrees (too low?), 1/8" or 1/4", 5.1-84(!) GPH available.

I was thinking of running three right after the turbo in the intake horn, each one on it's designated nitrous solenoid... That way I could vary which ones are running and have 7~or~so stages.

I don't know anything about hydraulic systems, so I don't know what kind of regulator would be my best bet.

I was thinking something like this.