blu_by_u

Diesel Head

- Joined

- Nov 16, 2007

- Messages

- 316

Progress has been slow. My drive to work is roughly 40-45 minutes so when I have been getting off work after 5pm, it's 6pm by the time I get home, then supper, spend a little bit of time with the family, etc.

I wanted to get the pump ready to install for good on the engine so I did a little prep work. Here I am removing an oil plug to make room for the pump oil line fitting. The instructions said to use the fitting right behind the factory oil line to the aux drive.

Here is the fitting in the block.

This is the restricted fitting in the pump.

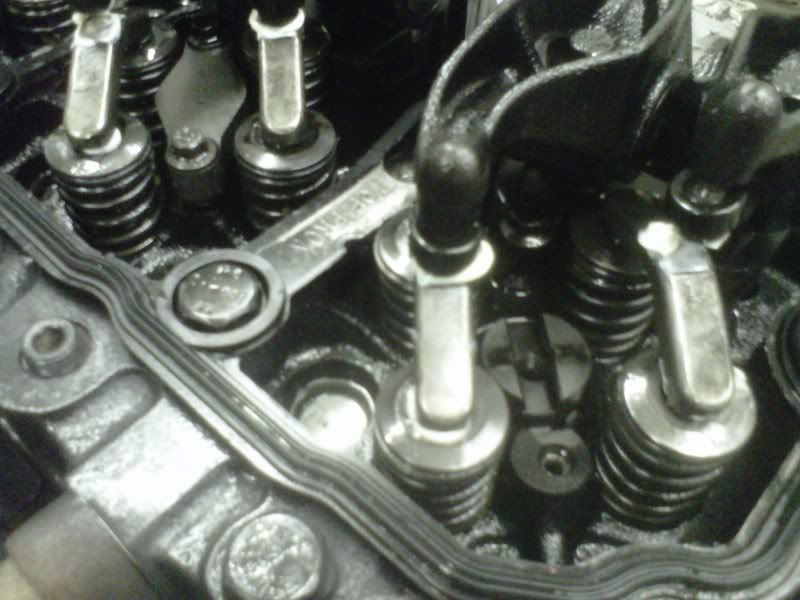

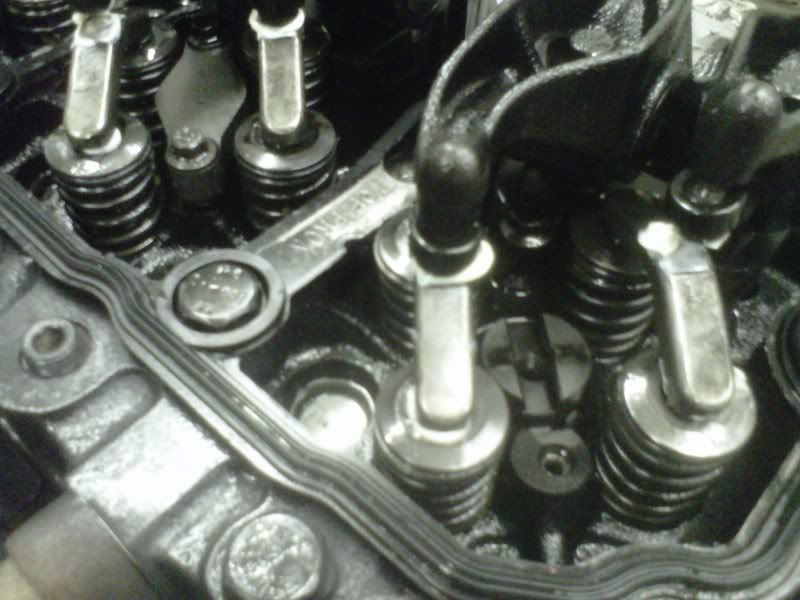

Next I moved on to pulling number one injector so that I could get a better idea of when the crank is at top dead center (TDC) for setting the valves. Started by removing the hold-down capscrew furthest away from the rocker levers. Then the injector hold-down slides right out (you'll see that the other hole is a slot).

Next I thread on the cross-over tube removal tool on.

Then I use a decent sized straight screwdriver to gently pry the tube out. Make sure that you pry it out as straight as possible to reduce the risk of damaging the O-rings on the tubes.

It's not a bad idea to pull the tubes first so that you don't forget. You 'can' forget to pull them, then damage them when you pull the injector out anyway!

To help get the injector out, I always use one of the shorter bolts that were used to clamp the injection lines down on the intake manifold. I simply thread it into the top of the injector body.

Then I take a decent sized straight screwdriver and use a headbolt as the fulcrum to pry the injector up. The tip of the screwdriver is under the head of the capscrew. You might need to adjust how far into the body that you thread the capscrew in.

Then use the capscrew as a handle and lift the injector straight up.

Since finding the exact TDC for setting the valves isn't critical, I simply used my double-ended pick to show the movement of the piston by gently placing it in the #1 injector hole.

My hands were pretty gouped up so I don't think I took any pics of setting the valves. It wasn't too exciting anyway. haha

Tonight on the way home I bought some 22gauge sheet metal and some tin snips to make a TDC pointer. I'm pretty happy with the way it turned out.

I just need to stop by the local Fastenal to get another double ended capscrew for the other mounting point.

Tomorrow my pilot bearing should be in at NAPA. I noticed that it didn't roll very smoothly so I need to pull the flywheel back off and change the pilot bearing. Oh well, better to do it now than AFTER I get everything put back together in the truck!

I wanted to get the pump ready to install for good on the engine so I did a little prep work. Here I am removing an oil plug to make room for the pump oil line fitting. The instructions said to use the fitting right behind the factory oil line to the aux drive.

Here is the fitting in the block.

This is the restricted fitting in the pump.

Next I moved on to pulling number one injector so that I could get a better idea of when the crank is at top dead center (TDC) for setting the valves. Started by removing the hold-down capscrew furthest away from the rocker levers. Then the injector hold-down slides right out (you'll see that the other hole is a slot).

Next I thread on the cross-over tube removal tool on.

Then I use a decent sized straight screwdriver to gently pry the tube out. Make sure that you pry it out as straight as possible to reduce the risk of damaging the O-rings on the tubes.

It's not a bad idea to pull the tubes first so that you don't forget. You 'can' forget to pull them, then damage them when you pull the injector out anyway!

To help get the injector out, I always use one of the shorter bolts that were used to clamp the injection lines down on the intake manifold. I simply thread it into the top of the injector body.

Then I take a decent sized straight screwdriver and use a headbolt as the fulcrum to pry the injector up. The tip of the screwdriver is under the head of the capscrew. You might need to adjust how far into the body that you thread the capscrew in.

Then use the capscrew as a handle and lift the injector straight up.

Since finding the exact TDC for setting the valves isn't critical, I simply used my double-ended pick to show the movement of the piston by gently placing it in the #1 injector hole.

My hands were pretty gouped up so I don't think I took any pics of setting the valves. It wasn't too exciting anyway. haha

Tonight on the way home I bought some 22gauge sheet metal and some tin snips to make a TDC pointer. I'm pretty happy with the way it turned out.

I just need to stop by the local Fastenal to get another double ended capscrew for the other mounting point.

Tomorrow my pilot bearing should be in at NAPA. I noticed that it didn't roll very smoothly so I need to pull the flywheel back off and change the pilot bearing. Oh well, better to do it now than AFTER I get everything put back together in the truck!