XLR8R

Crew Chief

- Joined

- Sep 10, 2007

- Messages

- 2,364

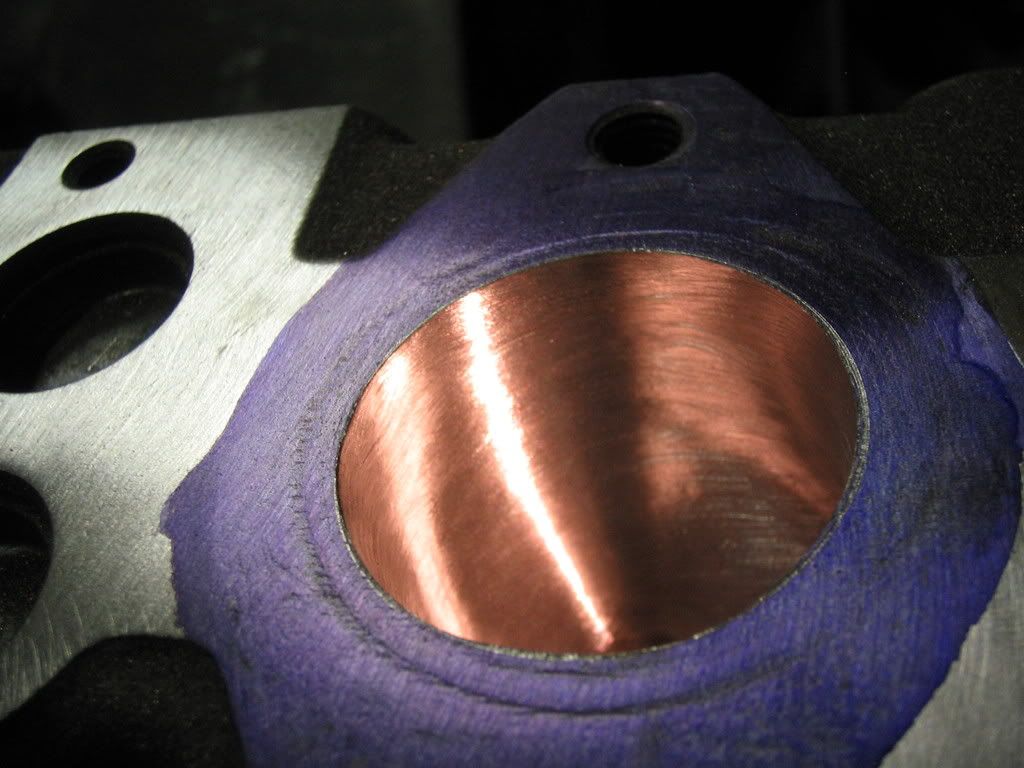

Anyone ever grind out the bottom of the exhaust ports of a CR to match an aftermarket manifold (full-round, same as the gaskets)? Short-side radius, if you will.

... can't imagine the step would be beneficial as anti-reversionary in a turbo exhaust tract.

... can't imagine the step would be beneficial as anti-reversionary in a turbo exhaust tract.