You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting splines onto a shaft?

- Thread starter Begle1

- Start date

Begle1

Active member

- Joined

- Nov 18, 2007

- Messages

- 4,178

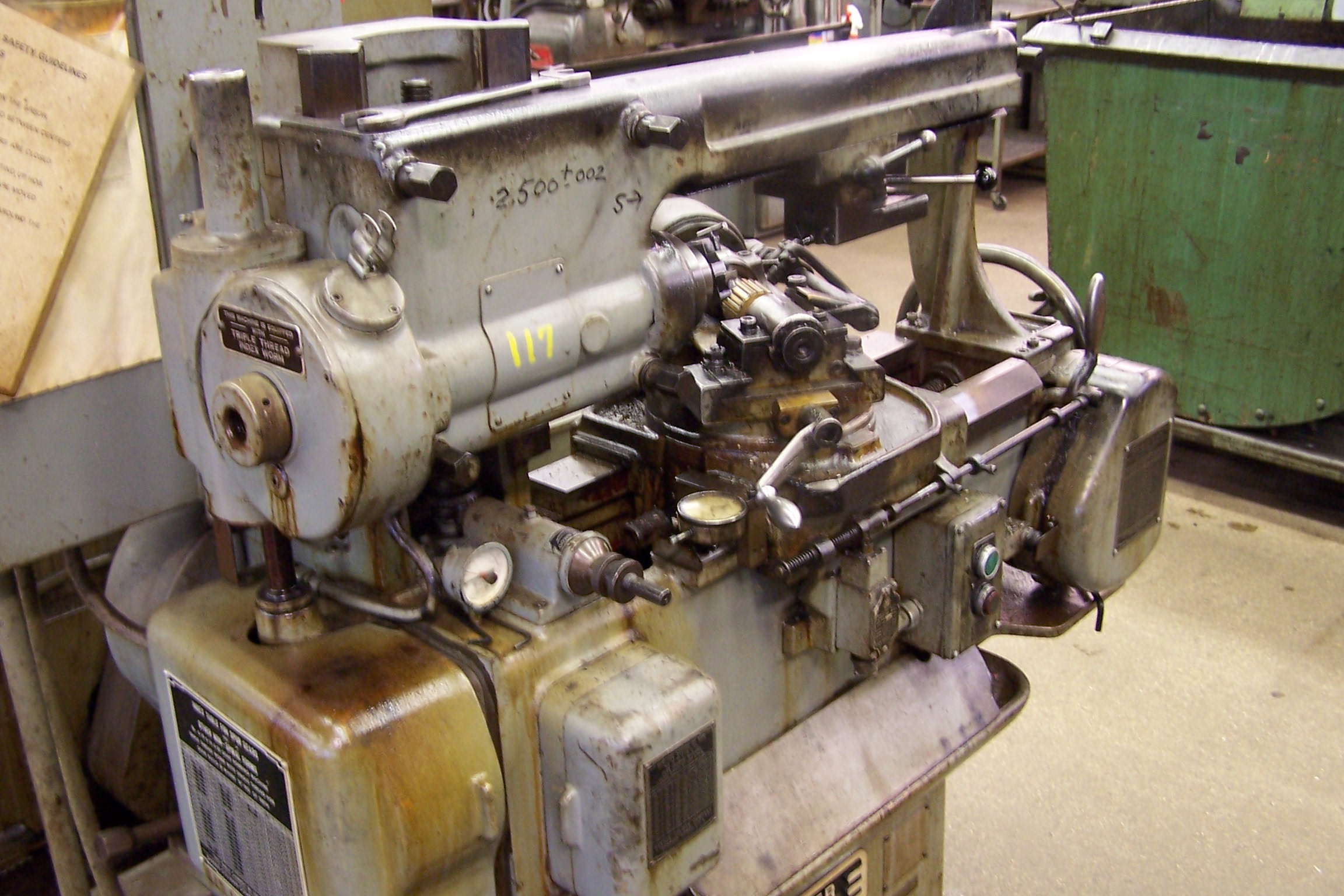

So they take one of these hootenaners...

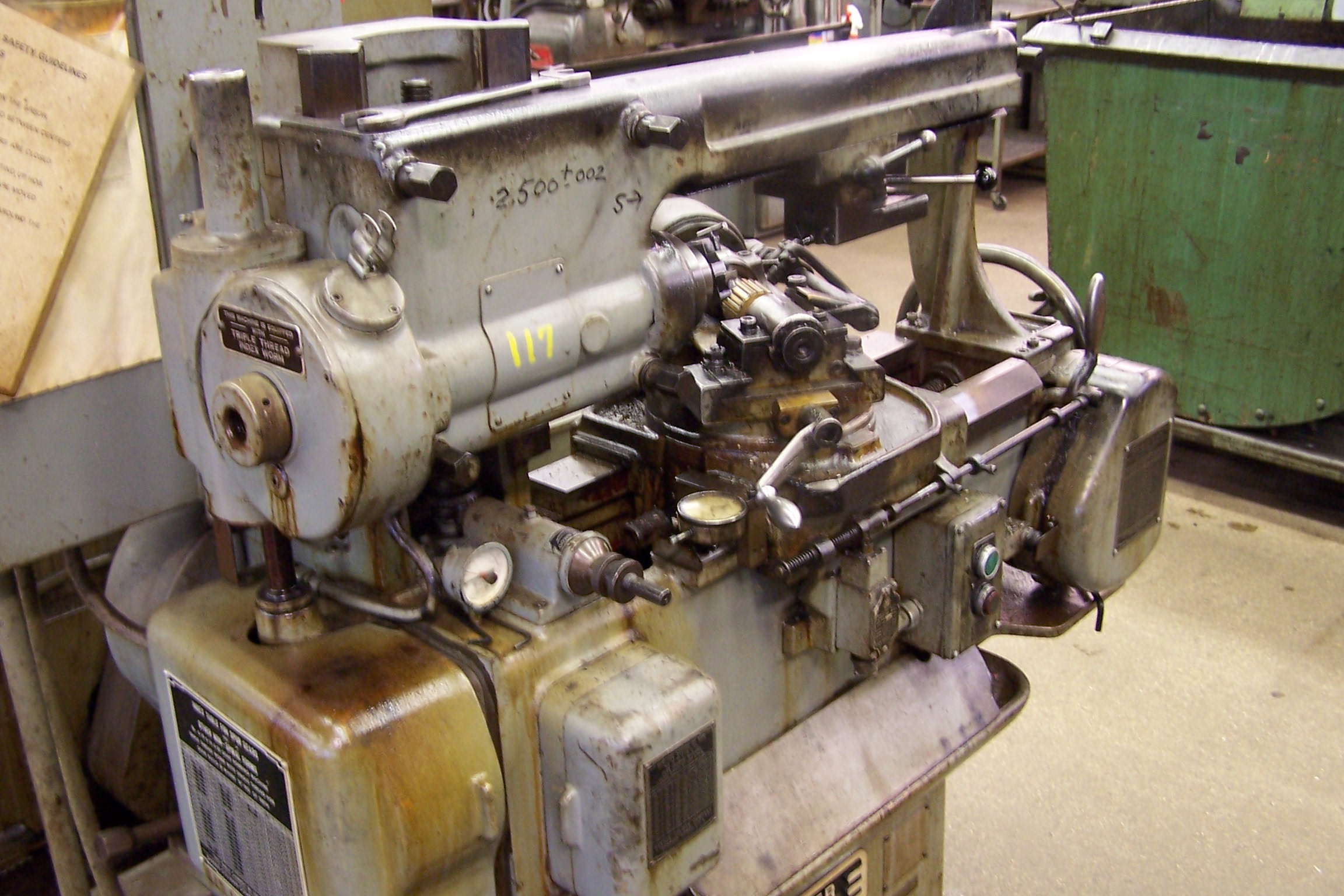

Put it on one of these wampuses...

And then let it do this sort of catybumpkin?

http://www.youtube.com/watch?v=dGfFw2wz7lk

If I need to say anything other than "I need this shaft splined to fit this hub" I'm screwed. LOL

Put it on one of these wampuses...

And then let it do this sort of catybumpkin?

http://www.youtube.com/watch?v=dGfFw2wz7lk

If I need to say anything other than "I need this shaft splined to fit this hub" I'm screwed. LOL

Begle1

Active member

- Joined

- Nov 18, 2007

- Messages

- 4,178

If your lucky enough you could find someone that rolls the splines. the other option is if they are straight splines is they can be broached on.

What's better why?

They're straight splines.

PASSENGER

Bells and Whistles

- Joined

- Jun 8, 2007

- Messages

- 267

Rolled, and broaching are lower tolerance production methods. I doubt you'll find someone to roll what you need for cheap. Broaching maybe, hobbing cost is going to depend on your material (how hard it is determines how long its going to take).

If you could find a local with a shaper and a indexing head they could make quick work of simple splines.

If you could find a local with a shaper and a indexing head they could make quick work of simple splines.