BullfrogJohnson

Black Smoke Junkie

- Joined

- Oct 18, 2007

- Messages

- 250

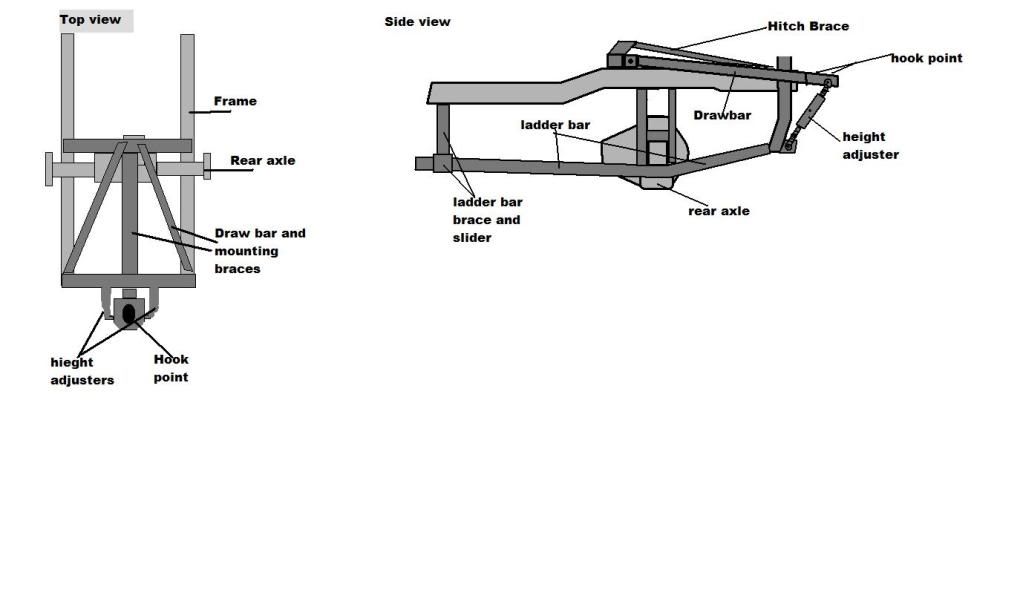

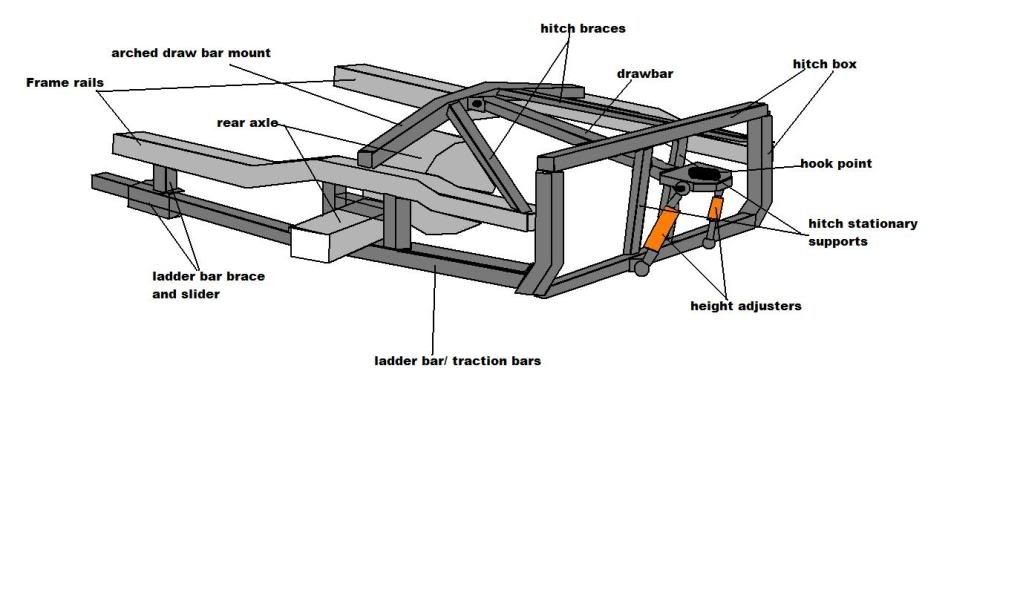

I am moving up to the 3.0 class and I am wanting to redo my hitch to meet the open hitch rules.

I would like to see some pics of a good draw bar setup and eveyones ideas on the best way to set them up. My truck is a ccsb.

I would like to see some pics of a good draw bar setup and eveyones ideas on the best way to set them up. My truck is a ccsb.