LNicholson

New member

- Joined

- Jan 10, 2009

- Messages

- 19

It's my first post here; I have been hanging out and reading for awhile.

Symptom - Low fuel pressure (5 pounds at idle, less while engine is under load), 12 psi with pump running and engine off.

Repair attempts:

-Yet another new lift pump on frame rail near tank. (Original lift pump for 97,000 miles, Carter 4601HP for over 100K miles, Holley Black for one year)

-Backflushed all diesel lines from injection pump to the fuel tank to ensure they were not plugged.

-New fuel filters. 100 micron before lift pump, and stock fuel filter in canister.

-New overflow valve on VP44.

I had a Holley Black, when it developed this problem (along with a leak from the weep hole) I bought a 35 gph Airtex to get me by and serve as a "toolbox spare" and ordered a 160 gph Aeromotive (it has not arrived yet).

The Airtex is currently installed. All of the factory lift pump wiring is bypassed and I run the fuel pump from a dash switch/fuse/relay setup wired directly into the batteries.

The fuel gauge is the digital gauge in the Attitude monitor. The pressure sender is located between the factory fuel filter and the injection pump. I have a hard time believing the sender is the problem, because with just the lift pump running (not the engine) it holds 12 pounds of pressure.

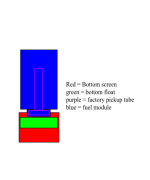

3/8 fuel line (that has worked perfectly for 140,000 miles) from the tank to the injection pump. Tapped the factory filter canister for 3/8 fittings both in and out, and found a metric adapter for the injection pump to take 3/8 fuel line. The only banjo fitting from the tank to the injection pump is the banjo fitting for the overflow valve.

I am out of ideas. All help will be appreciated.

Symptom - Low fuel pressure (5 pounds at idle, less while engine is under load), 12 psi with pump running and engine off.

Repair attempts:

-Yet another new lift pump on frame rail near tank. (Original lift pump for 97,000 miles, Carter 4601HP for over 100K miles, Holley Black for one year)

-Backflushed all diesel lines from injection pump to the fuel tank to ensure they were not plugged.

-New fuel filters. 100 micron before lift pump, and stock fuel filter in canister.

-New overflow valve on VP44.

I had a Holley Black, when it developed this problem (along with a leak from the weep hole) I bought a 35 gph Airtex to get me by and serve as a "toolbox spare" and ordered a 160 gph Aeromotive (it has not arrived yet).

The Airtex is currently installed. All of the factory lift pump wiring is bypassed and I run the fuel pump from a dash switch/fuse/relay setup wired directly into the batteries.

The fuel gauge is the digital gauge in the Attitude monitor. The pressure sender is located between the factory fuel filter and the injection pump. I have a hard time believing the sender is the problem, because with just the lift pump running (not the engine) it holds 12 pounds of pressure.

3/8 fuel line (that has worked perfectly for 140,000 miles) from the tank to the injection pump. Tapped the factory filter canister for 3/8 fittings both in and out, and found a metric adapter for the injection pump to take 3/8 fuel line. The only banjo fitting from the tank to the injection pump is the banjo fitting for the overflow valve.

I am out of ideas. All help will be appreciated.