moparman13045

New member

- Joined

- May 4, 2010

- Messages

- 20

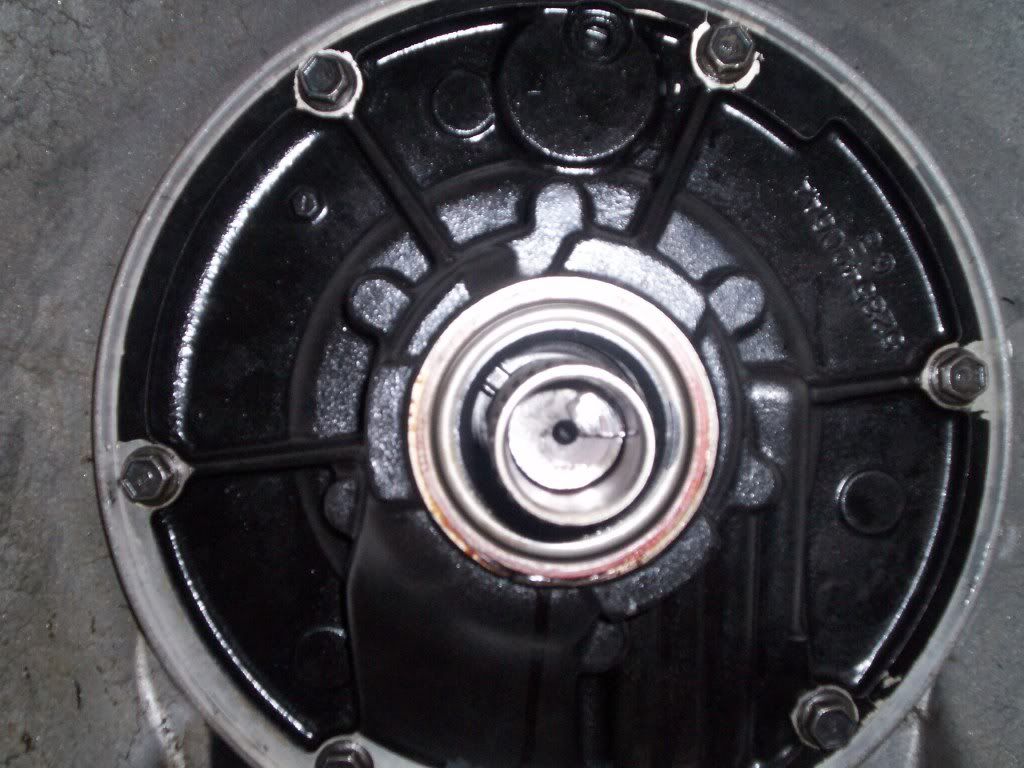

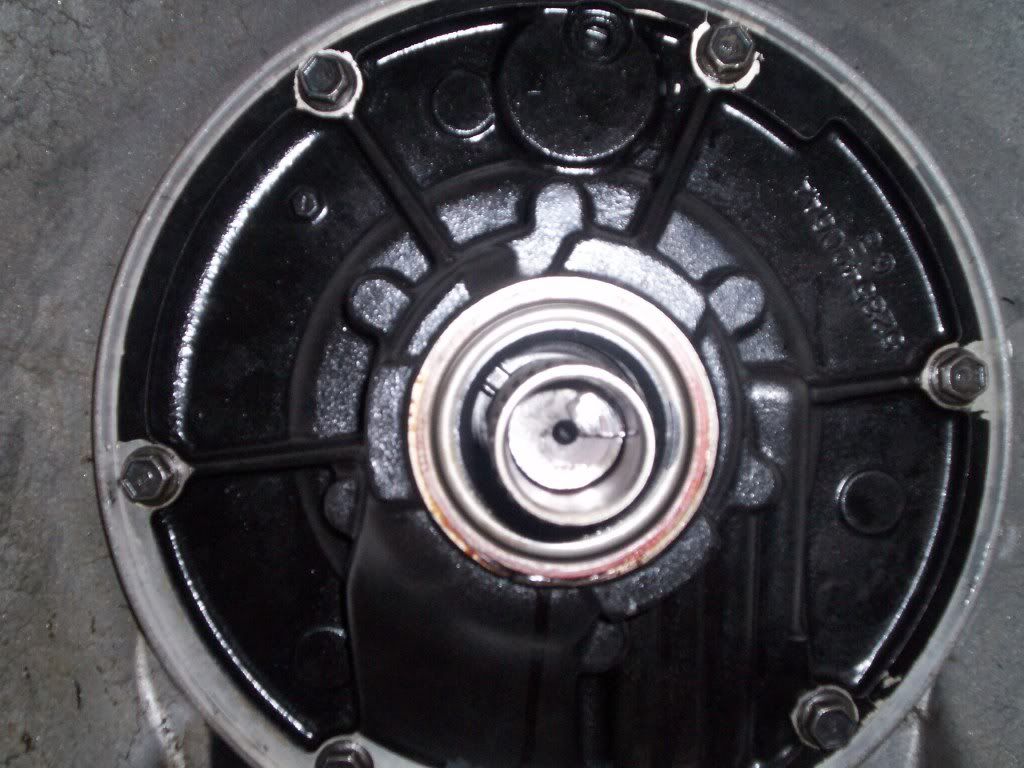

Well on the freeway the other night, a buddy of mine had my truck heard a loud bang, rpms hit redline, then it was like i was in neutral coasting. Here are some pics of the outcome, 05 dodge ats transmission, suncoast billet input shaft. Truck dynos at 527hp at wheels 1105 ft lbs. I think I may have got somewhat lucky, the break looks clean, no pieces to be found anywhere, and none look to be missing out of the broken halves. Piece that is in converter still is stuck though, so might have messed up something in converter, but what are you gonna do.

Here are some carnage pics hoping pump is ok...

If anybody has a stock good working order tranny I can buy just to put in the truck until I get this one fixed let me know!

Here are some carnage pics hoping pump is ok...

If anybody has a stock good working order tranny I can buy just to put in the truck until I get this one fixed let me know!