@ White Knight.

- The VE rotary pump isn't like the later P7100, etc. It's main-shaft seal gets shoved out of the case with much more than 20 or so psig fuel feed pressure.

- The stock/OEM lift-pump is of the diaphragm design and by design, produces right at 12psig with the engine free-reving to 2500rpms.

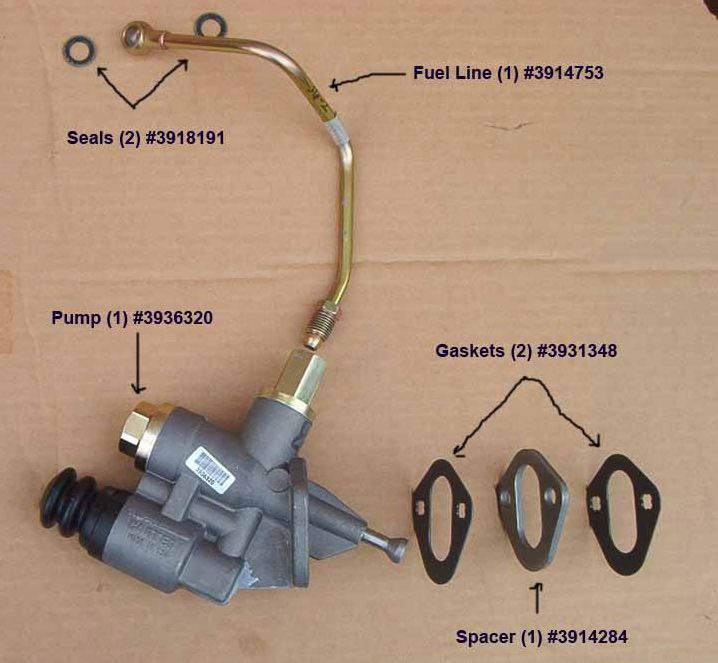

- It's common practice to replace the stock lift-pump with a agricultural app piston style lift-pump that is self regulating at about 15psig. It's good for a moderately bombed 1st gen.

- It's common to upgrade to the 2nd gen piston lift-pump when heavily bombing the 1st gen. As you may know, it is self regulating at about 45psig. As such, we have to regulate it's output to 20psig or less. further, the 2nd gen piston pump is of a larger piston displacement and as such, provides more volume supporting larger injectors while better maintaining feed pressure.

- It's common knowledge in the 1st gen community that we have to limit the VE's input pressure to a max of about 20psig. Don't we blow the seal unless it's been modified.

As you've pointed out, pumps move volume. Said volume encounters resistance to flow thus the pressure goes up. Certainly, with increased engine speed as well as demand for fuel, the resistance will drop thus does the pressure.

- > In the case of the VE rotary injection pump. It has dynamic injection timing that is Dependant on IP case pressure to function at it's intended range. A drop in fuel feed pressure will cause a drop in case pressure (under the right conditions) which will impact the dynamic timing function.

Make sense?