biggy238

Active member

- Joined

- Aug 3, 2008

- Messages

- 11,005

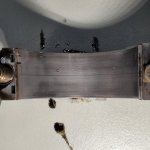

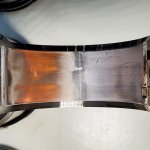

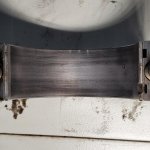

Well used.Damn that second bearing looks shot to me.

Sent from my motorola one 5G using Tapatalk

Well used.Damn that second bearing looks shot to me.

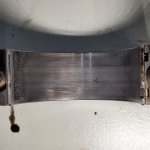

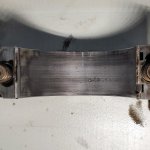

I would go 240. Could always get fancy and do 120 then 400 or so. Do you know what material the rings are?

I thought #5 was the problem. Looks like #6 has all the oil.

From Cummins manual...

edit- BRM (Brush Research Manufacturing) offers honing oil, but im sure youd be just fine following the cummins recomendation of 50/50 SAE 30 motor oil and diesel fuel.

Thanks for the info, does it happen to have the min/max spec for the bores?