WideOpenThrottl

New member

- Joined

- Apr 22, 2007

- Messages

- 119

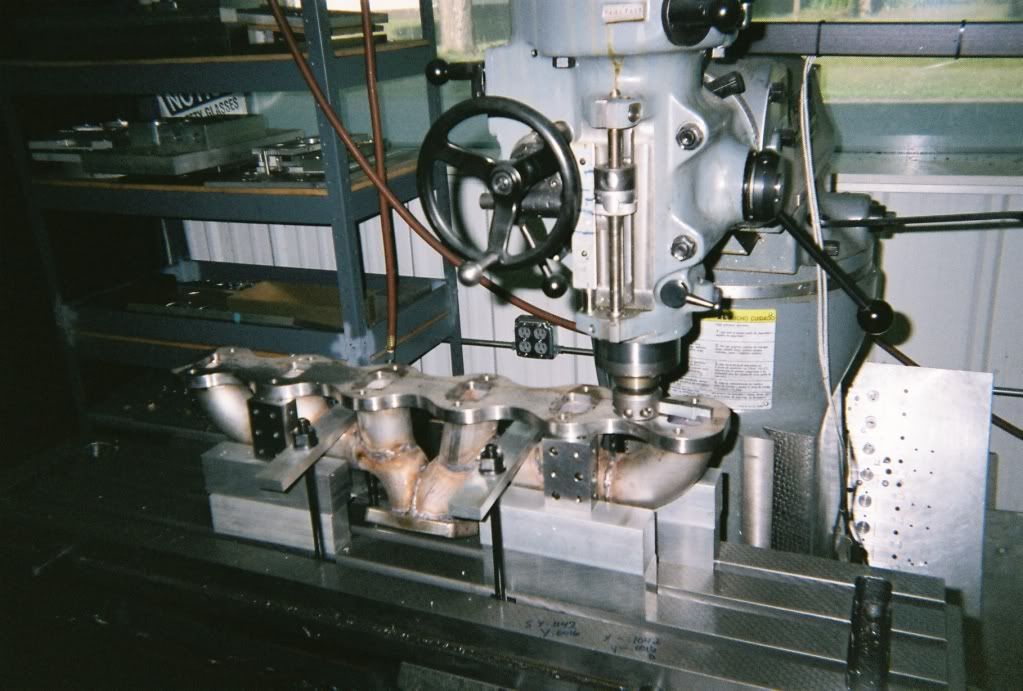

Well here is some pictures of the manifold that I built, still waiting to be polished of course. I built every thing myself from designing the head flange to CNC milling it out of 0.625" 304 stainless plate at my folk's shop, then tig welding it together. The pipe is 304ss schedule 40 and butt weld fittings.

Here is some pics of the way I went about it...

Flange has the rectangle ports to match the head then on the opposite side the pipe pockets were machined in so the fittings could drop in 1/4" to allow for fillet welds.

Flange awaiting welding,

Coping the fittings

Bolted up to the head

Compared to stock

Well I should be running my new engine with this manifold on the engine dyno here in 2-3 weeks. I am going to run it back to back with the stock manifold and possibly a ATS manifold comparison. It should move some serious air compared to the stocker.

I don't know the site's rules on this, but if anybody is interested I can sell ya the flanges steel or stainless now that I have the machine program written, just shoot me a pm.

Tim.

Here is some pics of the way I went about it...

Flange has the rectangle ports to match the head then on the opposite side the pipe pockets were machined in so the fittings could drop in 1/4" to allow for fillet welds.

Flange awaiting welding,

Coping the fittings

Bolted up to the head

Compared to stock

Well I should be running my new engine with this manifold on the engine dyno here in 2-3 weeks. I am going to run it back to back with the stock manifold and possibly a ATS manifold comparison. It should move some serious air compared to the stocker.

I don't know the site's rules on this, but if anybody is interested I can sell ya the flanges steel or stainless now that I have the machine program written, just shoot me a pm.

Tim.