@ Joesixpack I don’t it cheating, it’s being clever about it. All I do is to find TDC and if the trigger ring or tone gear is outside the engine like the Cummins QSK or ISB I count the teeth to the missing tooth from the crank sensor.

On engines where we don’t have any reference on timing I take cylinder one and change injection timing until we get some music from the engine.

And then we have engines with no cam sensor like the new XPI Scania engines. For this I programmed some code so the ECU can detect acceleration real fast as the ECU inject in two stroke mode @ start-up when the engine fires up it goes into 4 stroke mode having the cam in sync.

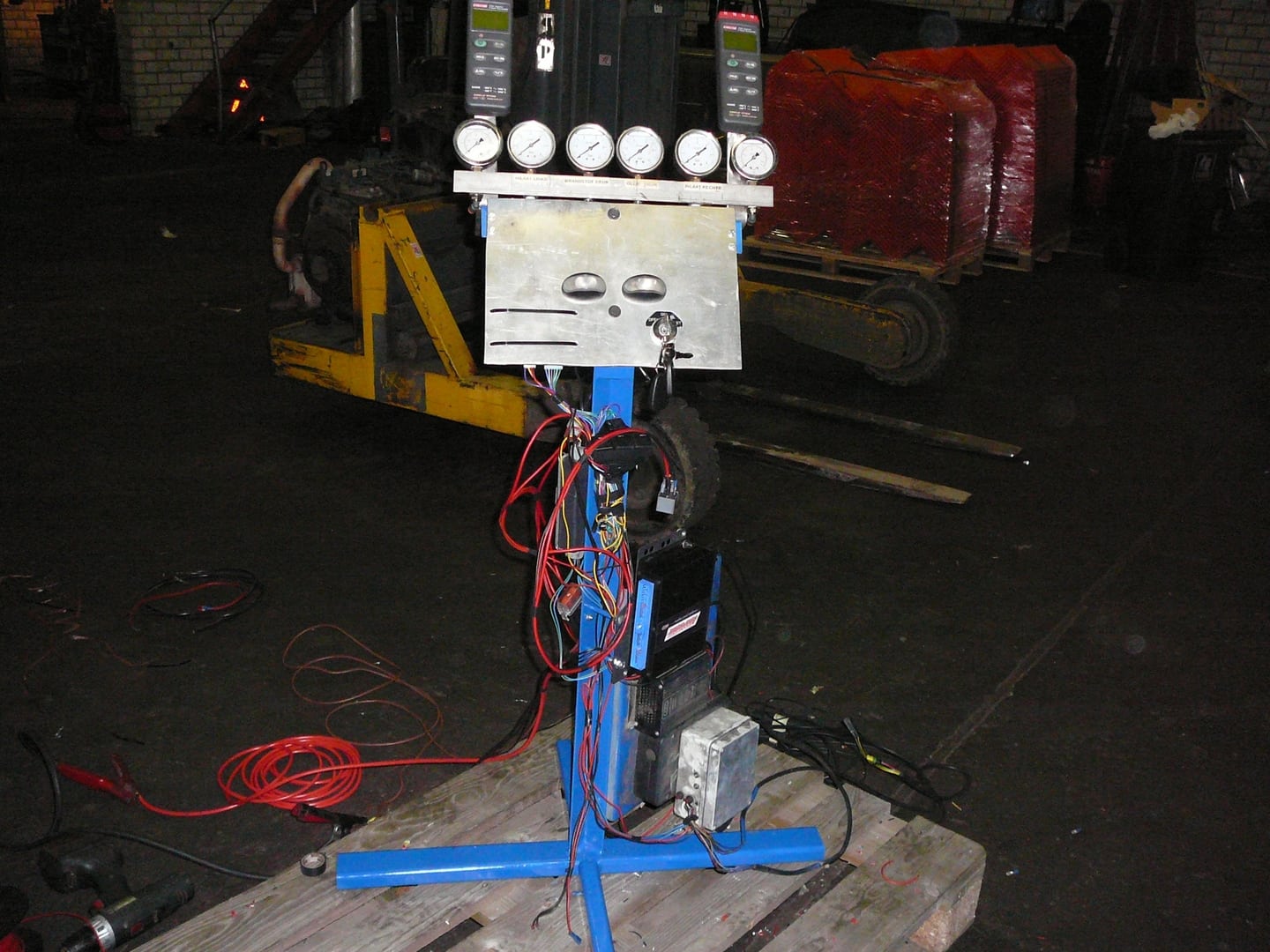

Also note the left gauge in the screen, that’s the fuel pressure gauge and red needle is real pressure and the green one is target pressure. When you accelerate the engine the red needle jumps up before the green one. This is an example of predictive mapping and how it works.

Also deceleration it takes some time before the rail pressure comes down as these engines have no bleed valve on the commonrail so this is normal.

I no longer use a injector flow map as it was close to impossible to have one made for every engine en still get poor results from it so I made injector response map that’s looks up fuel pressure and RPM as well as injector time ideal and dead time and now I got something that’s working for a whole range of injectors and yes you still need a injector flow map if you want to know the offset to the original injector used so you could ad % more fuelflow.

[ame="http://www.youtube.com/watch?v=4VFnHEg9YdI"]Scania 13 liter XPI running on Adaptronic DI ECU system. - YouTube[/ame]

@ Smoken Gun we did do a conversion of a V12 Detroit to commonrail. They now building a new engine as they had a coolant leak to 3 combustion chambers bending the crank and a conrod ending up in massive engine damage.

My experience is that’s it’s easier to get a commonrail running if you got the fuel pressure regulator set-up working for you. Engines with pump injectors are a lot harder to do as these injectors are really progressive on fuel flow so adding some fuel on idle make them jump up a lot in RPM as with a commonrail injector adding 50% more fuel on idle hardly makes a difference during an individual injector trim test.

Also on motorsport applications we change the injector control over RPM and engine load getting a load more fuel out of these injectors.

[ame="http://www.youtube.com/watch?v=dHgXpqu4nL0"]92 series V12 Detroit Diesel running on commonrail RV Engineering ECU systems 2900RPM run. - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=9sKQrpqEgnk"]V12 GM two stroke firs run on dyno with commonrail injection system done by RV Engineering - YouTube[/ame]

As for the Iveco injectors. The Iveco engine is a licence build Cummins engine and same goes for Paccar and some other brands but as far as I know the power rating on them is about the same.:umno:???

On engines where we don’t have any reference on timing I take cylinder one and change injection timing until we get some music from the engine.

And then we have engines with no cam sensor like the new XPI Scania engines. For this I programmed some code so the ECU can detect acceleration real fast as the ECU inject in two stroke mode @ start-up when the engine fires up it goes into 4 stroke mode having the cam in sync.

Also note the left gauge in the screen, that’s the fuel pressure gauge and red needle is real pressure and the green one is target pressure. When you accelerate the engine the red needle jumps up before the green one. This is an example of predictive mapping and how it works.

Also deceleration it takes some time before the rail pressure comes down as these engines have no bleed valve on the commonrail so this is normal.

I no longer use a injector flow map as it was close to impossible to have one made for every engine en still get poor results from it so I made injector response map that’s looks up fuel pressure and RPM as well as injector time ideal and dead time and now I got something that’s working for a whole range of injectors and yes you still need a injector flow map if you want to know the offset to the original injector used so you could ad % more fuelflow.

[ame="http://www.youtube.com/watch?v=4VFnHEg9YdI"]Scania 13 liter XPI running on Adaptronic DI ECU system. - YouTube[/ame]

@ Smoken Gun we did do a conversion of a V12 Detroit to commonrail. They now building a new engine as they had a coolant leak to 3 combustion chambers bending the crank and a conrod ending up in massive engine damage.

My experience is that’s it’s easier to get a commonrail running if you got the fuel pressure regulator set-up working for you. Engines with pump injectors are a lot harder to do as these injectors are really progressive on fuel flow so adding some fuel on idle make them jump up a lot in RPM as with a commonrail injector adding 50% more fuel on idle hardly makes a difference during an individual injector trim test.

Also on motorsport applications we change the injector control over RPM and engine load getting a load more fuel out of these injectors.

[ame="http://www.youtube.com/watch?v=dHgXpqu4nL0"]92 series V12 Detroit Diesel running on commonrail RV Engineering ECU systems 2900RPM run. - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=9sKQrpqEgnk"]V12 GM two stroke firs run on dyno with commonrail injection system done by RV Engineering - YouTube[/ame]

As for the Iveco injectors. The Iveco engine is a licence build Cummins engine and same goes for Paccar and some other brands but as far as I know the power rating on them is about the same.:umno:???