Hamilton Cams

ignorant

- Joined

- Jun 28, 2007

- Messages

- 2,639

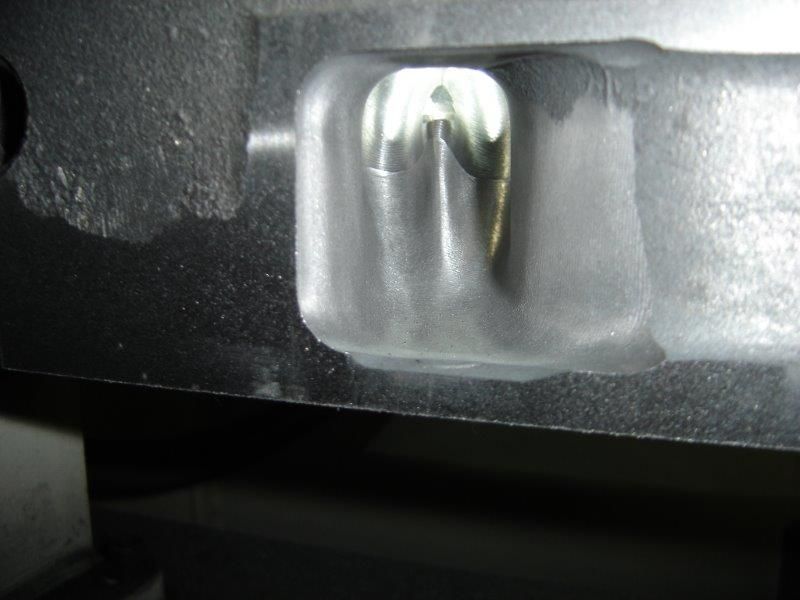

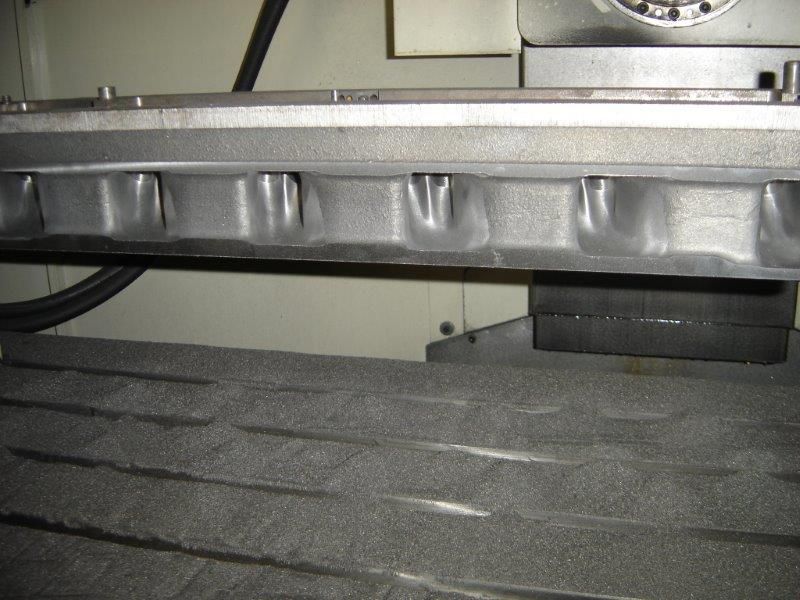

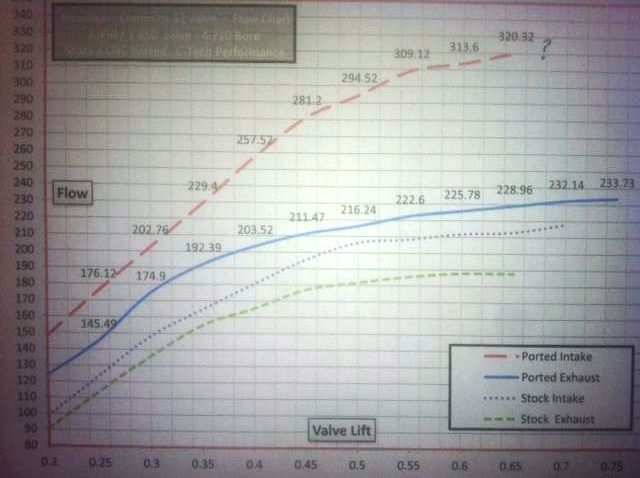

We have been working with C-tech for the last few months on getting a CNC program set up for our heads. Here is where we are at the moment. And they have the ability to go further if you ask nicely

http://c-techperformance.com/wp-content/uploads/2013/03/Hamilton-1.8502.png

http://c-techperformance.com/wp-content/uploads/2013/03/Hamilton-1.950-ping.png

http://c-techperformance.com/wp-content/uploads/2013/03/Hamilton-1.8502.png

http://c-techperformance.com/wp-content/uploads/2013/03/Hamilton-1.950-ping.png

Last edited: