sinfulcoin

Member

- Joined

- Jul 25, 2008

- Messages

- 247

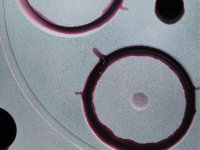

Yeah its not to bad down here. I have been down here about a year and like it so far. I have been latley staying at my brothers in Cincinnati as I am in the process of building my truck. On the head I bet I have 50-70 hrs in cutting of the intake, porting and polishing and other machine work:bang. Time really adds up quick. If you need burr's check out www.carbideburr.com. Great stuff and do not buy the ones for aluminum thinking it will cut faster:doh::doh: Really though if a guy takes his time in what he does it can turn out great. I have been able to save so much money doing things myself and having friends that work in machine shops:rockwoot::rockwoot:. Side note use an electric diegrinder if you can get your hands on one. They have alot more power and you don't have to worry about the compressor keeping up. Getting the speed right on your burrs will save the burrs. Faster is not always better in this case. Start with just the first cylinder and get those perfect then move on.