You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebirth of Monster Mudder

- Thread starter NakeDiesel

- Start date

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

lol, I can just imagine how much that would cost to coat a whole truck in that.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

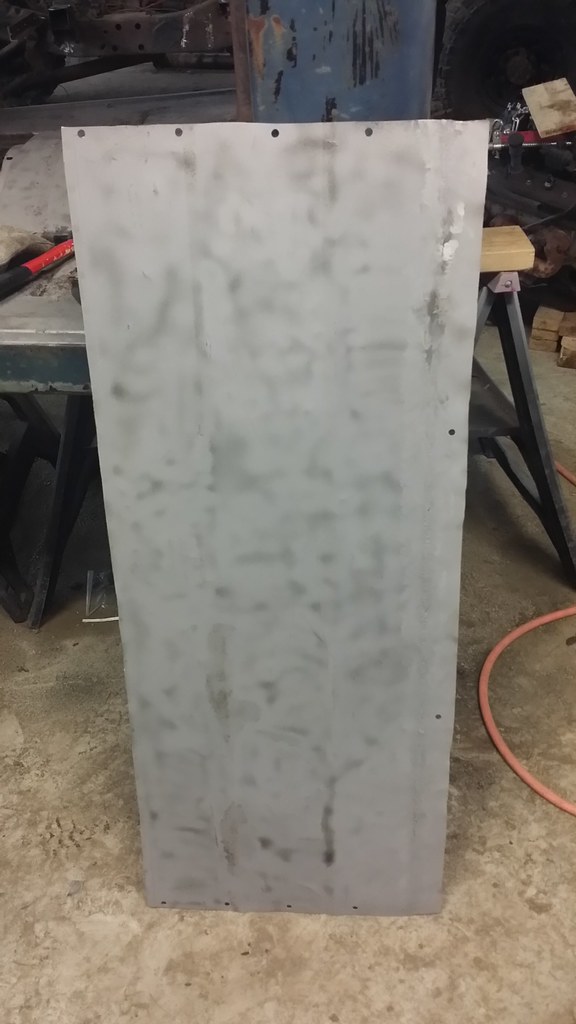

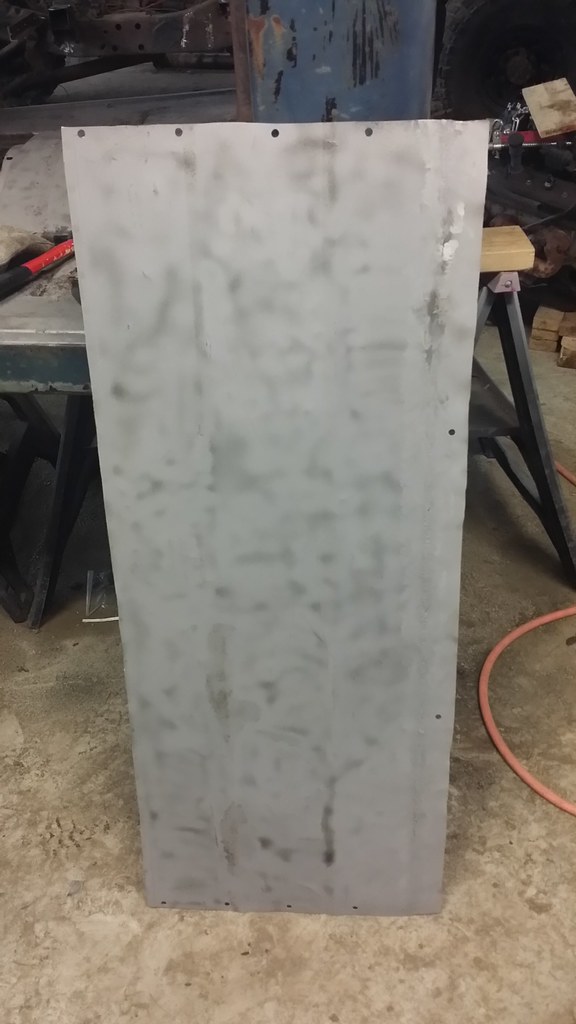

Woke up before dawn today so I spent some time out in the shop making replacement pieces of sheet metal and getting them welded in place for the back of the cab after I finished a big cup of coffee. Then at 8am, I made the grueling commute back to the house dodging piles of horse and cow crap to my office on the couch. I love working from the house....

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Finished welding in the new metal this afternoon during my lunch break. After work, it was starting to get dry out from the snow and rain, so I went back to sand blasting. Managed to get the front bed panel sand blasted and one side of the other bed side done before it got dark.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Finished blasting the cab of the truck today, took 800lbs of sand to finish it. I've been trying to recover as much as I could as I blasted, but with the wind gusts up to 30mph today, felt like I could just throw the sand in the air and it would have been quicker.

On a side note, the sand is mixing in nicely with the non draining clay soil I have and making a better entrance into the shop for the first bay. Next round, I'm going to move over a bay and add sand to the muddy ground there.

We have the cab laying on the back side now and I've cleaned it with the por 15 wax and grease remover, washed it with water, then dried it, then coated it in the metal prep for 20 minutes and washed that off. Now I'm waiting till the morning to give the bottom a coat of por 15.

On a side note, the sand is mixing in nicely with the non draining clay soil I have and making a better entrance into the shop for the first bay. Next round, I'm going to move over a bay and add sand to the muddy ground there.

We have the cab laying on the back side now and I've cleaned it with the por 15 wax and grease remover, washed it with water, then dried it, then coated it in the metal prep for 20 minutes and washed that off. Now I'm waiting till the morning to give the bottom a coat of por 15.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Today was a por day. Weather sucked, with the high occurring at 6am this morning and rainy and occasional sleet for most of the day. So I wasn't able to get any sand blasting done, but I managed to get 2 coats of por 15 applied to the bottom of the cab and also on the body mounts on the frame and the bed frame. I needed those covered before I put the cab back on.

While waiting for the por to dry, I finished welding the last two inches on each side of each wheel opening filler panel, fixed a few holes that sand blasting created or showed up on the fenders. I also welded a piece of 1/8" x 1 1/2" strap across the top of the front bed panel to give it a bit more strength since I cut the top round piece off of it.

I made the filler panels for the front grill and lower grill. Fixed the dents in the grill housing and then put a filler panel in the top of the grill housing where the radiator cap would have been.

Just washed off the por wash off the firewall and the back half of my truck frame, will let it dry over night and then apply the por metal prep in the morning so by mid day I can get them all coats of por 15 / chassis black.

While waiting for the por to dry, I finished welding the last two inches on each side of each wheel opening filler panel, fixed a few holes that sand blasting created or showed up on the fenders. I also welded a piece of 1/8" x 1 1/2" strap across the top of the front bed panel to give it a bit more strength since I cut the top round piece off of it.

I made the filler panels for the front grill and lower grill. Fixed the dents in the grill housing and then put a filler panel in the top of the grill housing where the radiator cap would have been.

Just washed off the por wash off the firewall and the back half of my truck frame, will let it dry over night and then apply the por metal prep in the morning so by mid day I can get them all coats of por 15 / chassis black.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Busy day today. Started off by washing the firewall and frame with metal prep, then washed it off after 20 minutes. While waiting for them to dry, I started sand blasting parts for the truck. Over the coarse of the day, I got the grill, hood, lower grill and finished the other side of the last bedside.

Since Friday morning, I've gone through 1200lbs of sand blasting metal. All I have left to blast are the two doors and two front fenders.

We finished up the day with mounting the cab back onto the frame of the truck. Talked to my brother today and we are going to plan on putting the cage in it next weekend. So while I'm waiting on that, I'm going to finish sand blasting metal, fix a few dents in the hood and weld up a few holes I found while blasting it.

Gave my son a turn at the sand blaster

Since Friday morning, I've gone through 1200lbs of sand blasting metal. All I have left to blast are the two doors and two front fenders.

We finished up the day with mounting the cab back onto the frame of the truck. Talked to my brother today and we are going to plan on putting the cage in it next weekend. So while I'm waiting on that, I'm going to finish sand blasting metal, fix a few dents in the hood and weld up a few holes I found while blasting it.

Gave my son a turn at the sand blaster

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Thanks, I'm ready to get the cage built and starting the body work.

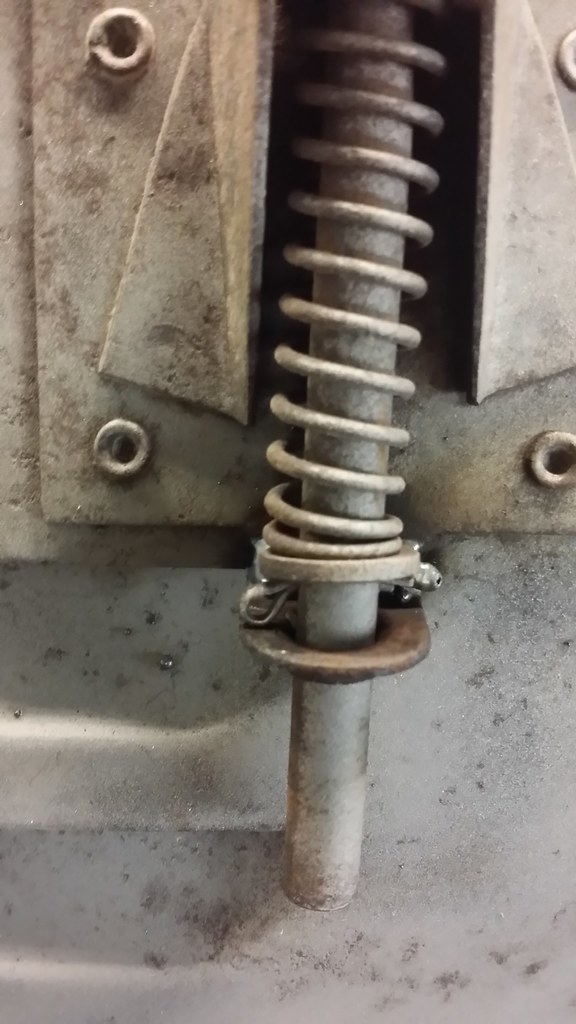

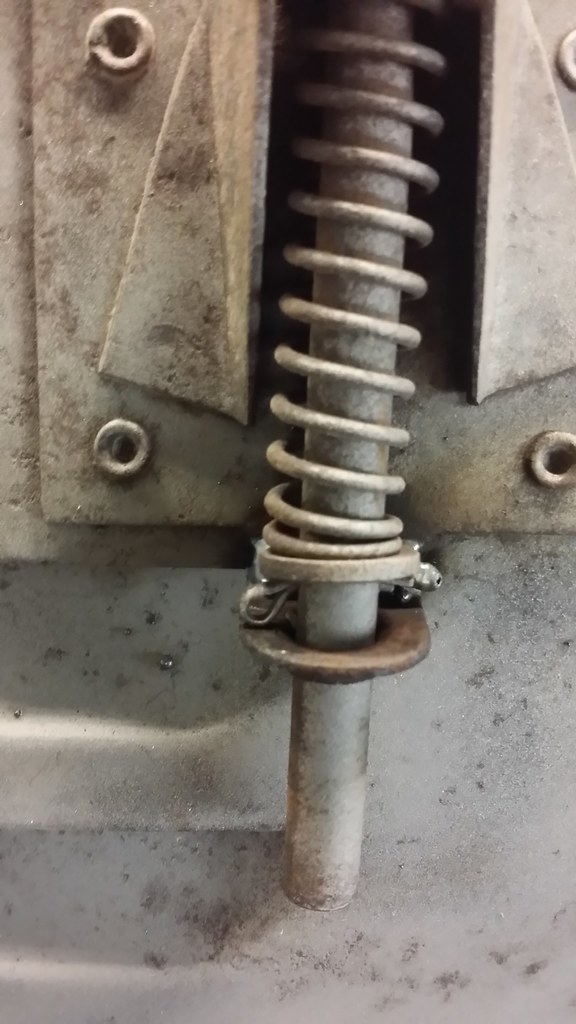

Tonight, I went through 4 80lb bags of sand on one front fender to get both sides of it clean. Down to 1 front fender and 2 doors to sand blast. After I finished the fender as the sun went down, I worked on getting the few small dents out of the hood panels, welding up the couple of holes I found/caused during sand blasting and fixed the two rear hood latches. One had a broken spring and both were missing that upper ring to keep the rod stable. I cut the rings off of the other hood I have that had broken hinges and welded them in place on the good hood.

Tonight, I went through 4 80lb bags of sand on one front fender to get both sides of it clean. Down to 1 front fender and 2 doors to sand blast. After I finished the fender as the sun went down, I worked on getting the few small dents out of the hood panels, welding up the couple of holes I found/caused during sand blasting and fixed the two rear hood latches. One had a broken spring and both were missing that upper ring to keep the rod stable. I cut the rings off of the other hood I have that had broken hinges and welded them in place on the good hood.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Decided not to sand blast today as we were having gust from the south up to 50 mph then switched directions about dark and blew that hard coming out of the south.

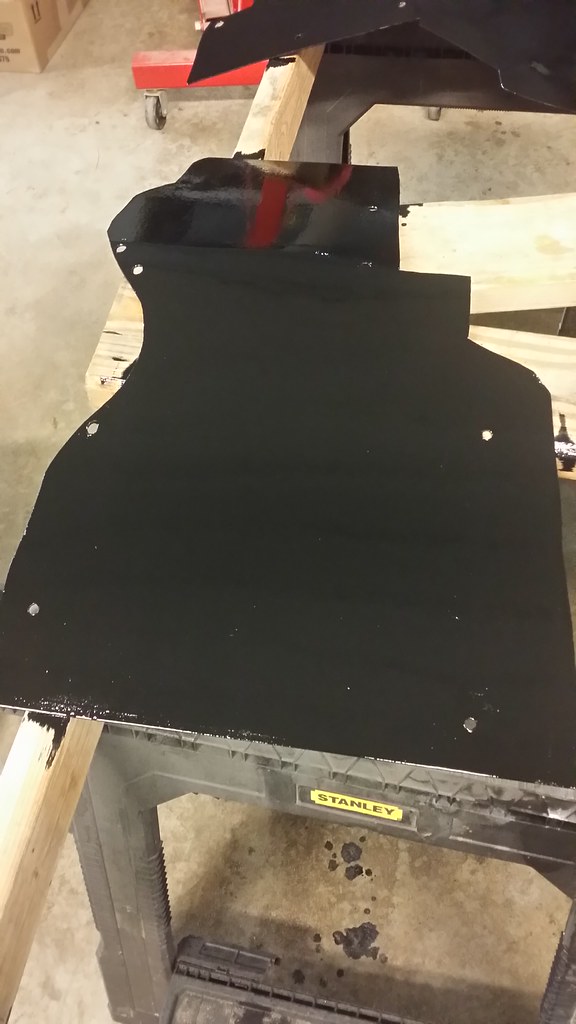

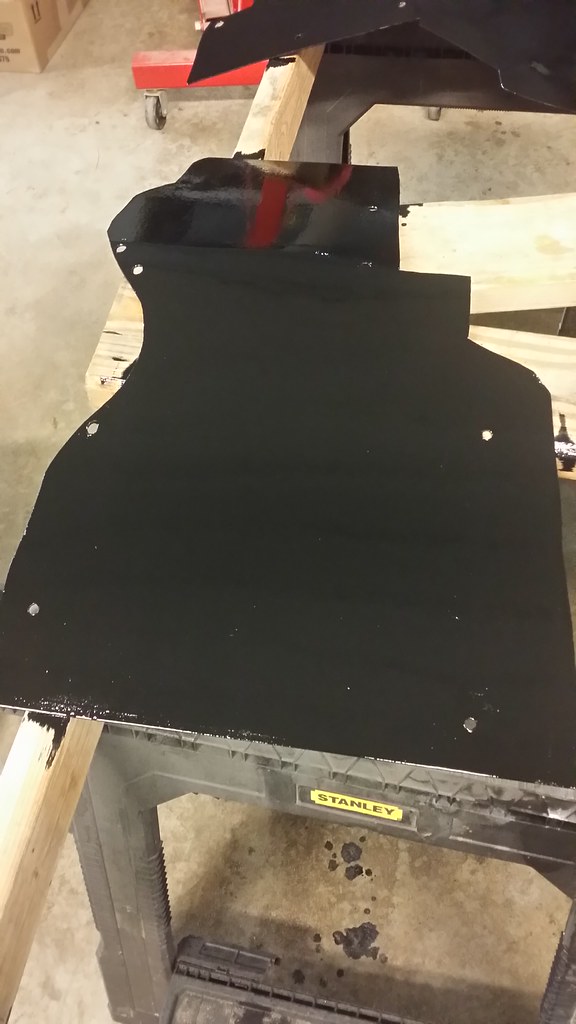

So tonight I prepped and painted the under sides of the two floor boards and the transmission tunnel with POR 15.

I also prepped and painted the inside part of the firewall.

Then I pulled the turbo off and exhaust manifold and redid the gaskets and torqued the allen bolts good. Then remounted and bolted on the turbo.

I picked up a nipple and collar and extended the oil supply into the turbo so my braided line would fit since I switched the turbo around. I think I need to get a little longer nipple to raise it up just a little bit more to move the line further off of the exhaust side of the turbo.

Any input?

So tonight I prepped and painted the under sides of the two floor boards and the transmission tunnel with POR 15.

I also prepped and painted the inside part of the firewall.

Then I pulled the turbo off and exhaust manifold and redid the gaskets and torqued the allen bolts good. Then remounted and bolted on the turbo.

I picked up a nipple and collar and extended the oil supply into the turbo so my braided line would fit since I switched the turbo around. I think I need to get a little longer nipple to raise it up just a little bit more to move the line further off of the exhaust side of the turbo.

Any input?

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Only managed to get a little done on the truck in the last two nights. I did pick up a longer nipple and that raised the oil line up a nice distance from the hot side of the turbo.

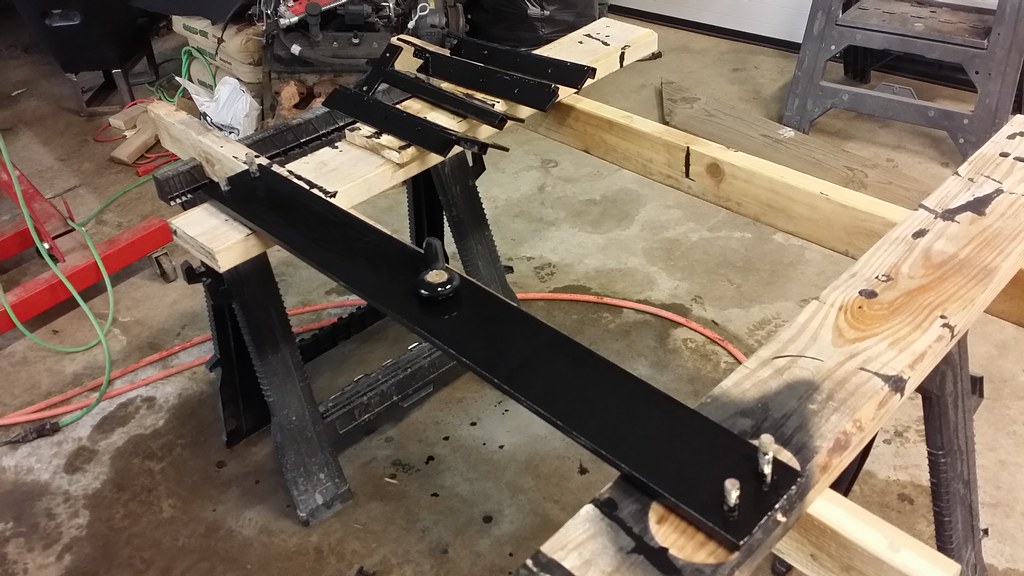

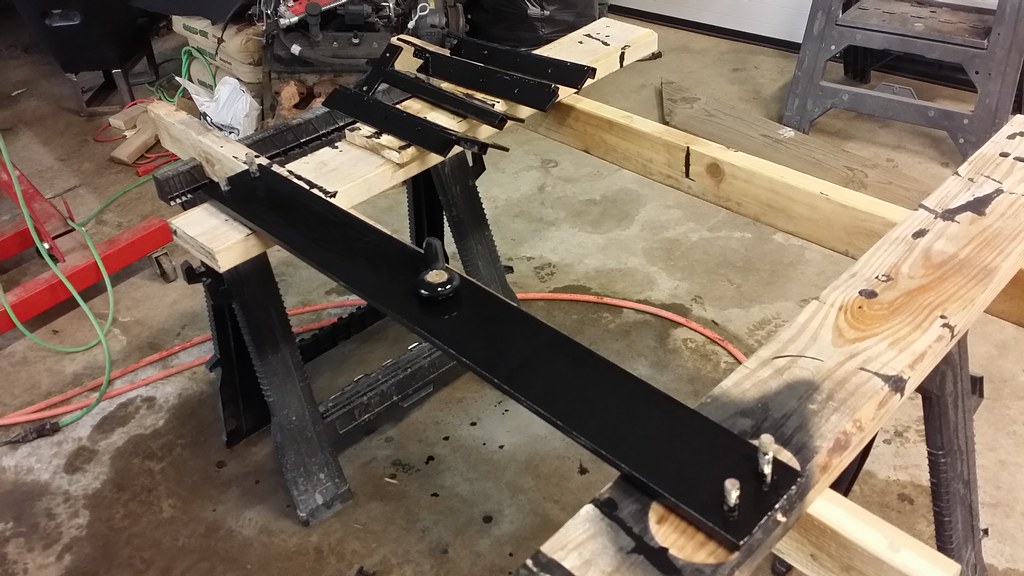

I finished getting the two floor boards coated in POR 15 / Chassis Black by doing the topsides today. I also welded on the floor tabs to my radiator support so that I can just cut the floor sections before the radiator and after the radiator to make putting the floor in easier. I also got the outside perimeter coated in Chassis Black today.

I have the inside cleaned and metal prepped and washed, just waiting for it and the trans cooler support to dry over night so that I can finish them off and bolt them into the truck.

My step daughter lost the driveshaft out of her truck going to school this morning while my son and I were an hour away for him to take his driving test to get his license. Once I found out what actually broke on the truck, told her to throw it in the bed of the truck, put in 4x4 hi and drive on to school. So I replaced the 3 month old U joints tonight in the rear drive shaft that I had replaced when I put in new seals in her transfer case. Guess I didn't get one of the c clips in good or one of them failed. While I was doing that, the step daughter changed her oil in her truck.... she was an oily mess when she was done....

Picked up the exhaust side yesterday for the internal part of the hood stack and had the vband weld on flange made while I was at H and H manufacturing. Sat the stack condom on it to keep dirt out while I figure out some other stuff and ready to cut and weld on the pipe.

I finished getting the two floor boards coated in POR 15 / Chassis Black by doing the topsides today. I also welded on the floor tabs to my radiator support so that I can just cut the floor sections before the radiator and after the radiator to make putting the floor in easier. I also got the outside perimeter coated in Chassis Black today.

I have the inside cleaned and metal prepped and washed, just waiting for it and the trans cooler support to dry over night so that I can finish them off and bolt them into the truck.

My step daughter lost the driveshaft out of her truck going to school this morning while my son and I were an hour away for him to take his driving test to get his license. Once I found out what actually broke on the truck, told her to throw it in the bed of the truck, put in 4x4 hi and drive on to school. So I replaced the 3 month old U joints tonight in the rear drive shaft that I had replaced when I put in new seals in her transfer case. Guess I didn't get one of the c clips in good or one of them failed. While I was doing that, the step daughter changed her oil in her truck.... she was an oily mess when she was done....

Picked up the exhaust side yesterday for the internal part of the hood stack and had the vband weld on flange made while I was at H and H manufacturing. Sat the stack condom on it to keep dirt out while I figure out some other stuff and ready to cut and weld on the pipe.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

I think I got a lot accomplished today on the truck. I have to cum a long the truck up on my trailer in the morning to haul the truck to my brothers tomorrow afternoon to build the cage and rear shock towers.

Today, I mounted the water to air intercooler and the air lines into the cab of the truck. I still need to wire the boots together and run my boost line for the gauge at some point. I also plan on cutting some rubber out and filling the area where I drilled the holes in the cab to make it more water tight.

I also mounted the hydro brake unit and the pedals on the inside. Routed all the hydraulic lines for the brakes and steering and miracle of miracles, the lines all fit almost perfect. I had to put a slight bend down on the two pressure lines at the brake side. Now I need to build new brake lines.

I coated some more stuff in POR 15 chassis black today and put the radiator support on the truck so we can use it as a reference point tomorrow for the rear cage supports.

Also mounted the transmission tunnel in the truck today. Cleaned up some flash rust in the cab from the por 15 metal prep over spray so that it's ready to be primed once I get the truck back home.

Today, I mounted the water to air intercooler and the air lines into the cab of the truck. I still need to wire the boots together and run my boost line for the gauge at some point. I also plan on cutting some rubber out and filling the area where I drilled the holes in the cab to make it more water tight.

I also mounted the hydro brake unit and the pedals on the inside. Routed all the hydraulic lines for the brakes and steering and miracle of miracles, the lines all fit almost perfect. I had to put a slight bend down on the two pressure lines at the brake side. Now I need to build new brake lines.

I coated some more stuff in POR 15 chassis black today and put the radiator support on the truck so we can use it as a reference point tomorrow for the rear cage supports.

Also mounted the transmission tunnel in the truck today. Cleaned up some flash rust in the cab from the por 15 metal prep over spray so that it's ready to be primed once I get the truck back home.

getblown5.9

Ceritified Kleenex Dealer

- Joined

- Aug 3, 2006

- Messages

- 7,259

what type of sand are you using in that blaster? same blaster I have and the blast media we have used before is high dollar, and if you get the cheaper larger grain stuff, it wont push through the hose and clogs up every 10 seconds. thinking sand might be cheaper.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

I have good luck running the black diamond fine that I get from tractor supply, it's 8.00 for 50 lbs. But what I have been using the most is a fine sand from quickcrete that is kiln dried. I pay 6.00 each for an 80lb bag of it and is what I've been using the most of for this project. I get it at Steve's wholesale tools. I rarely have an issue with clogging with the two different abrasives that I use. If you use sand be aware of silicosis and wear a good mask/air supply.

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

Today was cage building day, so I started the day out winching the truck onto the trailer twice.... Had it almost in position on the trailer and it slowly rolls over the two 4x4's that I was blocking it with. Controlled the roll off the trailer and started the process again using a snatch chain to keep it from repeating the second time. Hauled the truck to my brothers shop and spent the rest of the day watching the sky look like it was going to rain but not. We bent the major pieces with the truck sitting just outside of the shop so we had room to work, his little 40x60 shop is full of cars and junk. We finished the cage after about 7 hours of working on it, still no rain. Ran in the house to grab a quick bite to eat and came outside and it was pouring rain. So my son and I rushed to get the truck unloaded into the shop and get my plasma cutter unloaded as well that I brought home from my brother shop where it's been sitting and used there for the last 4 years. We spent about 40 minutes drying all the bare sheet metal off with the air nozzle and the heat gun.

My BFW steering tool

The back part of the cage in the cab sits on a 2x2x3/16 square tube running across the cab, I still need to drill through it and the cab and into the frame and I will bolt the cage to the frame there. The back frame tie in is welded to 2x2x1/4 angle iron where I will drill it out and bolt it to the frame. The front is welded to a 4x4 plate that we covered where the body mount bolt goes and welded it to the floor of the cab as well.

I have to order a new seat though, my plastic race seat won't work, it has too much angle in it for me to have enough leg room, so I'm going to order an aluminum seat with a 10 degree back so I can move the seat back 4 to 6 inches so I have leg room to operate the pedals.

I think we have the steering figured out. I will get it installed once I get the seat in from summit and have it mounted in place. Still need to figure out my brake and gas pedals.

My BFW steering tool

The back part of the cage in the cab sits on a 2x2x3/16 square tube running across the cab, I still need to drill through it and the cab and into the frame and I will bolt the cage to the frame there. The back frame tie in is welded to 2x2x1/4 angle iron where I will drill it out and bolt it to the frame. The front is welded to a 4x4 plate that we covered where the body mount bolt goes and welded it to the floor of the cab as well.

I have to order a new seat though, my plastic race seat won't work, it has too much angle in it for me to have enough leg room, so I'm going to order an aluminum seat with a 10 degree back so I can move the seat back 4 to 6 inches so I have leg room to operate the pedals.

I think we have the steering figured out. I will get it installed once I get the seat in from summit and have it mounted in place. Still need to figure out my brake and gas pedals.

CorneliusRox

Seasoned Rookie

- Joined

- Dec 13, 2012

- Messages

- 4,154

What are you aiming for on weight with this? I can't tell if it'll weight more of less! Looking good though for sure!

NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

The truck at the beginning of last season weighed 5700 lbs. with a weight bias of 53% front / 47% rear. I'm hoping for at least 500 lbs of weight reduction. I would like more, but won't know for sure till it's all together and I haul it to the truck scales.

CorneliusRox

Seasoned Rookie

- Joined

- Dec 13, 2012

- Messages

- 4,154

Wow 5700... That's impressive. I see why you had a carbon fiber stack now ;-)

What did you do to get down to that? I'm extremely close to 8000lbs with a full tank and me in it.

What did you do to get down to that? I'm extremely close to 8000lbs with a full tank and me in it.

dvst8r

Unobtainium

- Joined

- Feb 16, 2008

- Messages

- 2,053

Not sure if that is a finished cage or not, but I would consider adding \ / below your spreader bar on your main hoop tying into that 2X2X 3/16" square tube.

Also are there going to be any occupant restraint bars? Typically a diagonal bar running from just below shoulder height down to where the front part of the cage ties into the floor.

Also are there going to be any occupant restraint bars? Typically a diagonal bar running from just below shoulder height down to where the front part of the cage ties into the floor.