ClamDigger4

New member

- Joined

- Feb 25, 2010

- Messages

- 1,733

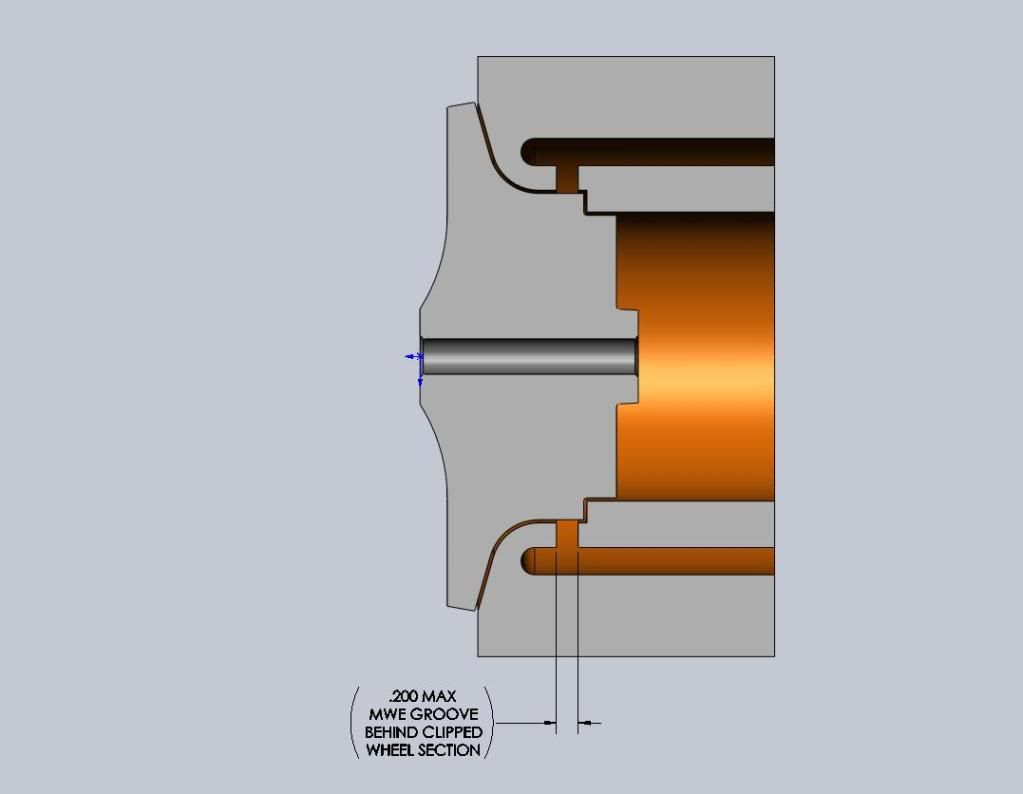

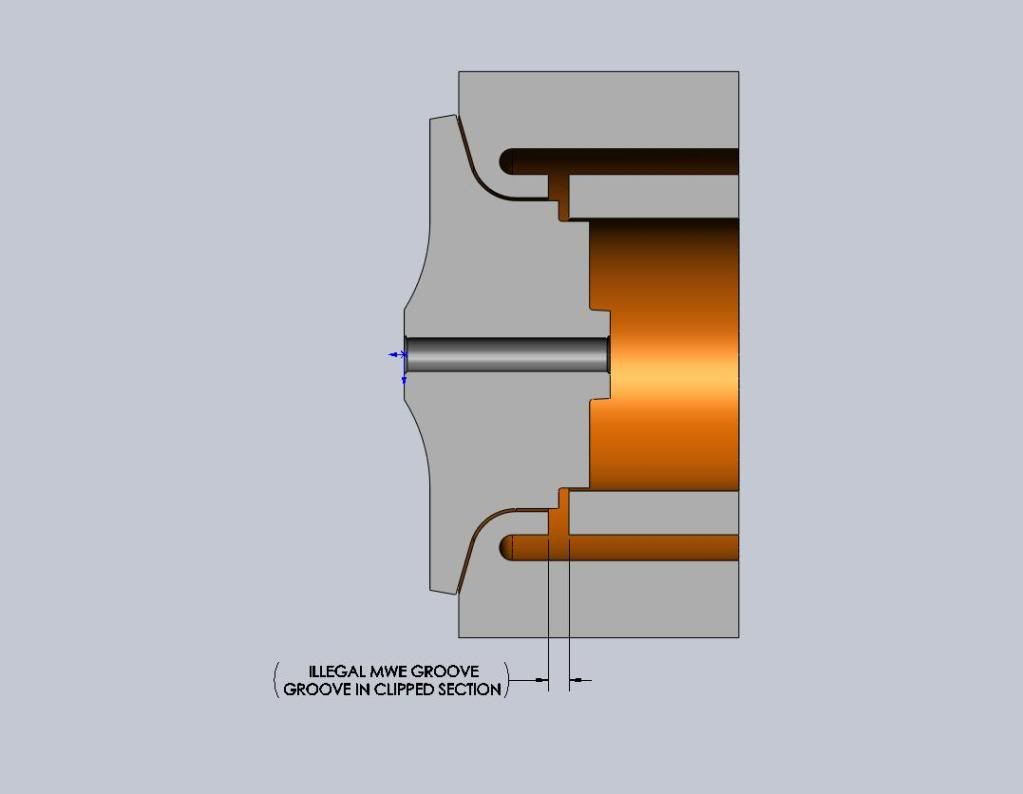

Map groove can not be forward of the compressor wheel, if you move it forward allowing the diameter to be bigger you to open up the area at the clip from .200 to say .400 it will draw more air past the .200 part this takes some pretty creative cover work but it can be done, you can feed the clipped part anyway you want, everything that ran last year is still legal

So according to this

So...

Legal

Not Legal

Or am I missing something?

both of these are legal

from phone