You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Setting pump timing....

- Thread starter HRDROKN

- Start date

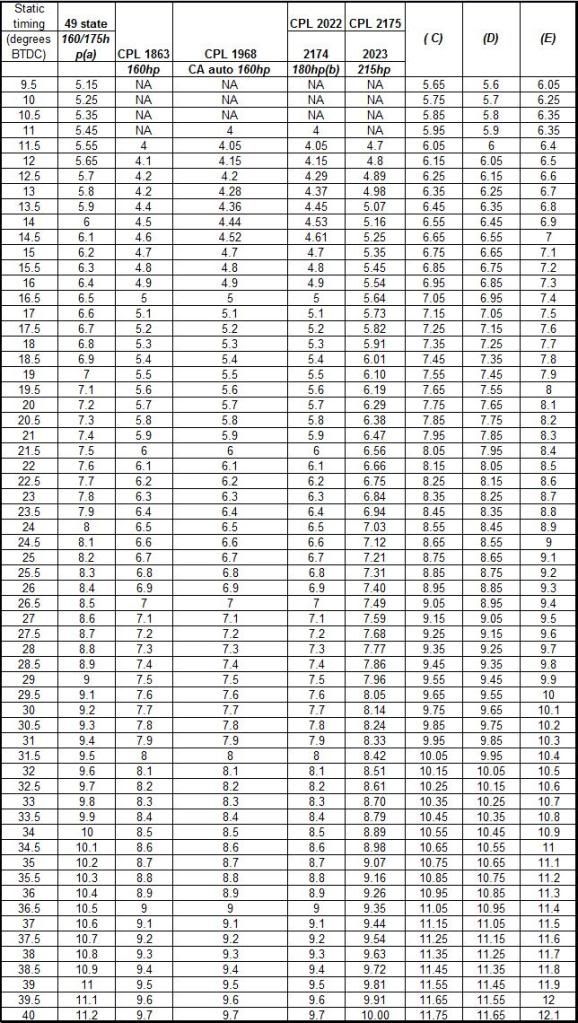

OK.... I found a chart and it looks like the correct lift for 20* is 5.7mm for a 180hp pump.

That sound correct? Why do the 160/175hp pumps have a different lift for the same 20* ?

:what:

Those pumps have different cams.

97' 180hp is what i have ESN 56346456 CPL is 2174 and for 20* of timing it is 5.7mm of lift. you are correct.

for the pump timing procedue here it goes...if you know you plunger lift for your cpl of that engine, or for that pump, install your dial indicator, set the indicator between 7.0, and 9.0mm on the small inner dial. barr the engine counter clock wise untill you hit the inner base circle of the cam on the pump, the dial indicator will be dropping. it will drop, stop, and begin to rise almost immediately, when you get to where it stops, stop rotating the engine, zero your dial indicator, when it stops your on the inner base circle of the cam. barr the engine clockwise utill you get the desired amount of lift, watch the gauge, depending on what gauge you are using,(i have the snapon timing kit) one revolution of the big dial indicator is 2mm of lift, soo keep and eye on the gauge. once you get the right amount of lift, stop, pull the pump gear, make sure that the lift did not change, if it did, repeat that step. if it did not change, barr the engine counter clockwise 20-30 deg. of engine rotation to remove greartrain lash between the crank, and cam gear, and then clockwise backup to tdc. clean the shaft really well with contact cleaner, you want no oil on the shaft at all, and seat the gear on the shaft, keep a slight counter clockwise pressure on the gear while you seat it, this will remove the gear lash inbetween the camshaft gear, and the pump gear, torque to 150ft. lb. go back, and back the engine off of tdc, bring back up to tdc, and verify that the plunger lift is where it needs to be at tdc, and you're done! hope this helps.

Wes

for the pump timing procedue here it goes...if you know you plunger lift for your cpl of that engine, or for that pump, install your dial indicator, set the indicator between 7.0, and 9.0mm on the small inner dial. barr the engine counter clock wise untill you hit the inner base circle of the cam on the pump, the dial indicator will be dropping. it will drop, stop, and begin to rise almost immediately, when you get to where it stops, stop rotating the engine, zero your dial indicator, when it stops your on the inner base circle of the cam. barr the engine clockwise utill you get the desired amount of lift, watch the gauge, depending on what gauge you are using,(i have the snapon timing kit) one revolution of the big dial indicator is 2mm of lift, soo keep and eye on the gauge. once you get the right amount of lift, stop, pull the pump gear, make sure that the lift did not change, if it did, repeat that step. if it did not change, barr the engine counter clockwise 20-30 deg. of engine rotation to remove greartrain lash between the crank, and cam gear, and then clockwise backup to tdc. clean the shaft really well with contact cleaner, you want no oil on the shaft at all, and seat the gear on the shaft, keep a slight counter clockwise pressure on the gear while you seat it, this will remove the gear lash inbetween the camshaft gear, and the pump gear, torque to 150ft. lb. go back, and back the engine off of tdc, bring back up to tdc, and verify that the plunger lift is where it needs to be at tdc, and you're done! hope this helps.

Wes

White Knight

New member

- Joined

- Aug 18, 2007

- Messages

- 1,380

rattlindodge

New member

- Joined

- Jun 27, 2008

- Messages

- 507

oops

Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,310

The easiest way to set timing is to remove the plug on the side of the pump and use a mirror to look for timing lobe/pin and center it in the hole. This should coincide with TDC for cylinder #1.

Next look at the data tag on the side of the timing case/front cover assembly and see what the stock timing was set at. On my 95' junker, it was set at 12.3*.

Next measure the diameter of the dampner. Pi x diameter = circumference.

Basically if you wanted say 20* on my truck you do quick math and realize you need to advance the timing 7.7* or (7.7/360) times the diameter. On my truck, to go up to 24* total or 12 more * advance, I had roll the dampner back about .84". I had a mark for TDC on my dampner so I simply made a mark .84" back from TDC.

Next remove the pump nut. Then make sure motor is at TDC before you use a puller to remove the pump gear. Once the gear is loose, roll the motor back to your mark .84" in my case. Check with you mirror to make sure the pump pin/lobe is still centered in the hole. If it is, clean the pump shaft and gear as best you can with brake parts cleaner.

Install the pump gear and give it a few small wacks to help seat it onto the shaft. Install the lockwasher and nut and tighten to about 15 ft lbs. Check timing by making sure the pump lobe/timing pin is still centered in the hole when the motor is on the timing mark you made .84" before TDC mark in my case. If the timing is correct, torque the pump nut to at least 144 ft lbs but 150-160 is preferred so it timing is less likely to slip.

This proceedure is very similar to the plunger lift method. Instead of fiddling with the fuel line, DV socket, and machinist dial, you simply remove a plug, and turn the motor over till the timing nob/lug/pin thing is centered in the hole and you make one precise measurement on the dampner.

In my opinion, people spend too much time trying to get timing set to an exact degree. 23.75* vs 24.25* is going to run the same on most trucks. If you need more exact timing, you'd better have a timing light handy because DV's, Turned Pump barrels, injector pop off pressure, lift pump pressure, line size, etc all play a role in where the final timing ends up.

Next look at the data tag on the side of the timing case/front cover assembly and see what the stock timing was set at. On my 95' junker, it was set at 12.3*.

Next measure the diameter of the dampner. Pi x diameter = circumference.

Basically if you wanted say 20* on my truck you do quick math and realize you need to advance the timing 7.7* or (7.7/360) times the diameter. On my truck, to go up to 24* total or 12 more * advance, I had roll the dampner back about .84". I had a mark for TDC on my dampner so I simply made a mark .84" back from TDC.

Next remove the pump nut. Then make sure motor is at TDC before you use a puller to remove the pump gear. Once the gear is loose, roll the motor back to your mark .84" in my case. Check with you mirror to make sure the pump pin/lobe is still centered in the hole. If it is, clean the pump shaft and gear as best you can with brake parts cleaner.

Install the pump gear and give it a few small wacks to help seat it onto the shaft. Install the lockwasher and nut and tighten to about 15 ft lbs. Check timing by making sure the pump lobe/timing pin is still centered in the hole when the motor is on the timing mark you made .84" before TDC mark in my case. If the timing is correct, torque the pump nut to at least 144 ft lbs but 150-160 is preferred so it timing is less likely to slip.

This proceedure is very similar to the plunger lift method. Instead of fiddling with the fuel line, DV socket, and machinist dial, you simply remove a plug, and turn the motor over till the timing nob/lug/pin thing is centered in the hole and you make one precise measurement on the dampner.

In my opinion, people spend too much time trying to get timing set to an exact degree. 23.75* vs 24.25* is going to run the same on most trucks. If you need more exact timing, you'd better have a timing light handy because DV's, Turned Pump barrels, injector pop off pressure, lift pump pressure, line size, etc all play a role in where the final timing ends up.

Jim Fulmer

New member

- Joined

- May 6, 2006

- Messages

- 5,013

That is the ways I do it except I break the nut loose then when it's lined up I pin the pump so it doesn't move, makes life easier, I probably performed this procedure 50 times.

Jim

Jim

Tate

What?

- Joined

- Nov 5, 2007

- Messages

- 3,419

The easiest way to set timing is to remove the plug on the side of the pump and use a mirror to look for timing lobe/pin and center it in the hole. This should coincide with TDC for cylinder #1.

Next look at the data tag on the side of the timing case/front cover assembly and see what the stock timing was set at. On my 95' junker, it was set at 12.3*.

Next measure the diameter of the dampner. Pi x diameter = circumference.

Basically if you wanted say 20* on my truck you do quick math and realize you need to advance the timing 7.7* or (7.7/360) times the diameter. On my truck, to go up to 24* total or 12 more * advance, I had roll the dampner back about .84". I had a mark for TDC on my dampner so I simply made a mark .84" back from TDC.

Next remove the pump nut. Then make sure motor is at TDC before you use a puller to remove the pump gear. Once the gear is loose, roll the motor back to your mark .84" in my case. Check with you mirror to make sure the pump pin/lobe is still centered in the hole. If it is, clean the pump shaft and gear as best you can with brake parts cleaner.

Install the pump gear and give it a few small wacks to help seat it onto the shaft. Install the lockwasher and nut and tighten to about 15 ft lbs. Check timing by making sure the pump lobe/timing pin is still centered in the hole when the motor is on the timing mark you made .84" before TDC mark in my case. If the timing is correct, torque the pump nut to at least 144 ft lbs but 150-160 is preferred so it timing is less likely to slip.

This proceedure is very similar to the plunger lift method. Instead of fiddling with the fuel line, DV socket, and machinist dial, you simply remove a plug, and turn the motor over till the timing nob/lug/pin thing is centered in the hole and you make one precise measurement on the dampner.

In my opinion, people spend too much time trying to get timing set to an exact degree. 23.75* vs 24.25* is going to run the same on most trucks. If you need more exact timing, you'd better have a timing light handy because DV's, Turned Pump barrels, injector pop off pressure, lift pump pressure, line size, etc all play a role in where the final timing ends up.

The downside to that method is that the timing pin isn't always at the correct position, so you could still be going in blind. Same issue with lift as well, if you happen to get an oddball pump. Thats where a timing light is priceless.