Cross posted on the other Cummins Forum as well.

Hey Guys,

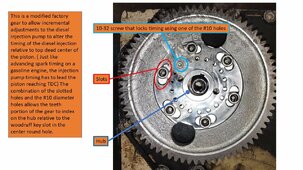

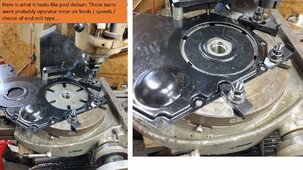

I am in process of modifying the front timing cover of my 96 12 Valve to provide access to my adjustable P7100 Pump Gear. I realize aftermarket aluminum covers are available, and I took a good look at them. But I want to see if I can pull this off myself and be satisfied with the results. I purchased a DCEC chinese cover as I didn't want to cut up my factory cover. I was a little disappointed that it didn't have the doubler plate tacked inside, but for $54 shipped to my door...oh well. Over the past couple of years I have purchased a few DCEC items through DB Sales on both the Jungle Site and Flea-Bay. I have been completely satisfied up to this point.

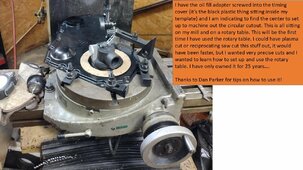

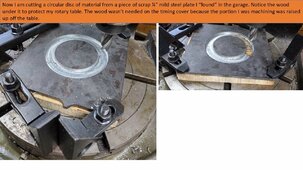

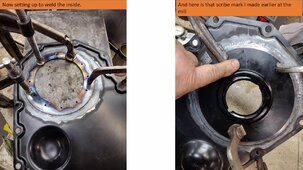

I will be using an aftermarket gear case as a welding fixture to help keep the adapter straight / reduce the chance of the heat warping the cover.

I have attached pictures of my progress so far. I will drill the holes for the fasteners after the adapter is welded to the cover.

Hey Guys,

I am in process of modifying the front timing cover of my 96 12 Valve to provide access to my adjustable P7100 Pump Gear. I realize aftermarket aluminum covers are available, and I took a good look at them. But I want to see if I can pull this off myself and be satisfied with the results. I purchased a DCEC chinese cover as I didn't want to cut up my factory cover. I was a little disappointed that it didn't have the doubler plate tacked inside, but for $54 shipped to my door...oh well. Over the past couple of years I have purchased a few DCEC items through DB Sales on both the Jungle Site and Flea-Bay. I have been completely satisfied up to this point.

I will be using an aftermarket gear case as a welding fixture to help keep the adapter straight / reduce the chance of the heat warping the cover.

I have attached pictures of my progress so far. I will drill the holes for the fasteners after the adapter is welded to the cover.

Attachments

-

IMG_20240909_173027187_HDR.jpg158.4 KB · Views: 8

IMG_20240909_173027187_HDR.jpg158.4 KB · Views: 8 -

IMG_20240909_173032747_HDR.jpg152 KB · Views: 5

IMG_20240909_173032747_HDR.jpg152 KB · Views: 5 -

IMG_20240909_173041155_HDR.jpg157.6 KB · Views: 6

IMG_20240909_173041155_HDR.jpg157.6 KB · Views: 6 -

IMG_20240909_173127210_HDR.jpg162.5 KB · Views: 5

IMG_20240909_173127210_HDR.jpg162.5 KB · Views: 5 -

IMG_20240909_173308421_HDR.jpg154.8 KB · Views: 8

IMG_20240909_173308421_HDR.jpg154.8 KB · Views: 8 -

IMG_20240909_173435618_HDR.jpg148.4 KB · Views: 8

IMG_20240909_173435618_HDR.jpg148.4 KB · Views: 8

Last edited: