sundaybacon

Dat ass

- Joined

- Oct 25, 2012

- Messages

- 61

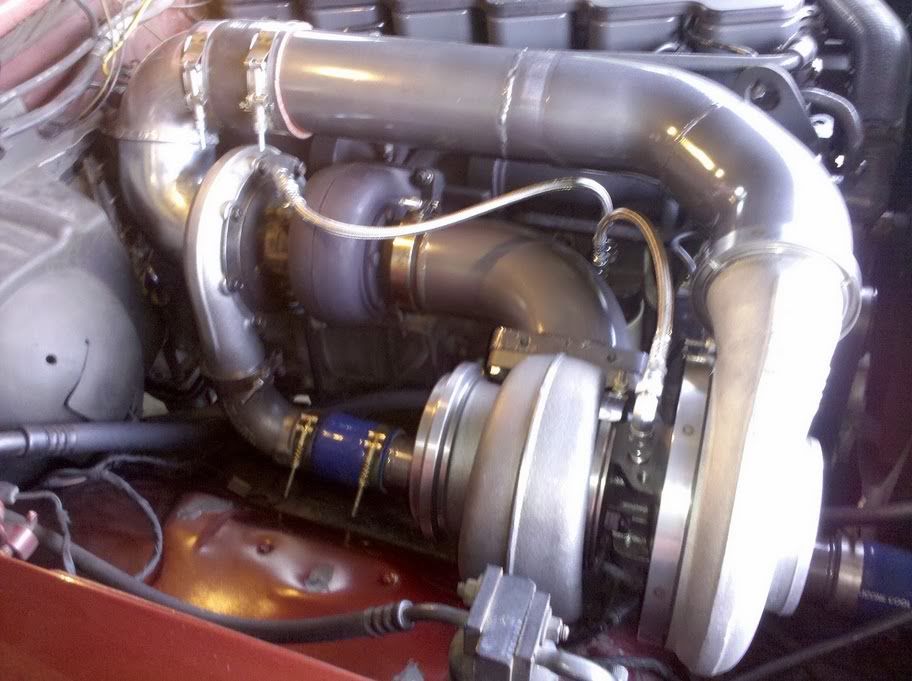

Trying to decide how I should plumb the twins in my first gen. Being that I have a bit more room to work with then the newer trucks, I'm thinking I want to try something a little different.

I really like how lostnwalmart mounted his primary. Only thing is the length of the hot pipe has me concerned.I Keep reading it has an effect on spool up. But no one has really provided any proof to this. I'm building a set of towing twins so response is key. But I like the idea of having the primary right there when you open the hood, for shock factor and making it easier to wrench on things.

I mocked my hx55 up below the 341 the traditional way(over/under), and it would be a tight squeeze to the frame rail, that's why I'm looking to other options.

I really like how lostnwalmart mounted his primary. Only thing is the length of the hot pipe has me concerned.I Keep reading it has an effect on spool up. But no one has really provided any proof to this. I'm building a set of towing twins so response is key. But I like the idea of having the primary right there when you open the hood, for shock factor and making it easier to wrench on things.

I mocked my hx55 up below the 341 the traditional way(over/under), and it would be a tight squeeze to the frame rail, that's why I'm looking to other options.