You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Windowing a block is overplayed?

- Thread starter BC847

- Start date

1972RedNeck

New member

- Joined

- Sep 21, 2014

- Messages

- 93

What's the backstory?

CorneliusRox

Seasoned Rookie

- Joined

- Dec 13, 2012

- Messages

- 4,154

Clapped out!

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

Damn. Whats the drive pressure numbers on that triple set?

Snedge

Comp Diesel Sponsor

- Joined

- Sep 1, 2006

- Messages

- 18,884

Damn. Whats the drive pressure numbers on that triple set?

I'm going to guess zero at this point..

BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

What we have here is a 27ish year old stock/OEM short block with 295,502 miles on it. I've pretty-much drove the **** out of it. A lot of the typical Thursday night Test-N-Tune followed by a trip to the coast the following Friday over the last ten years.

'93 5.9 12V. Well flowing head (195in/220out), 188/220 cam, recently two S362 into one S362 (150ish lb/min). 12mm VE w/working dynamic-timing, honed 5x.018 (4.7ltr/min). All the other mess.

Cranked it up to go and make a dyno appointment. Noticed the oil pressure was a little lower than normal. Oil level good. On the way home I heard what initially sounded like I'd air-bound an injector (it's a VE thing). Within a moment, that apparent miss turning into a very pronounced stomping in the block. No oil pressure. Oil level's still good.

The engine still ran. The hardness of the stomp followed the throttle.

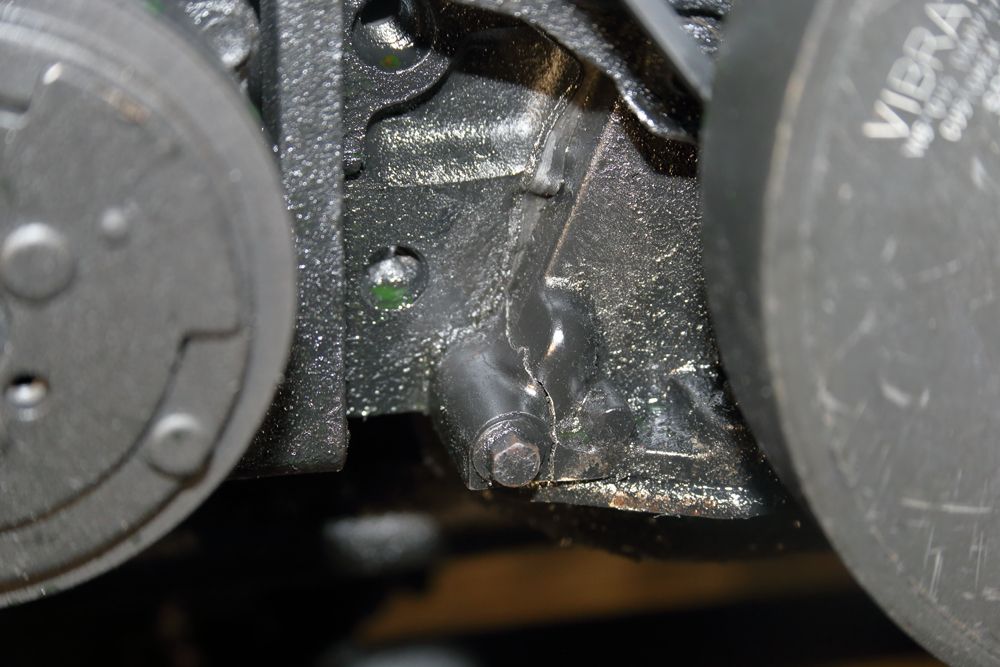

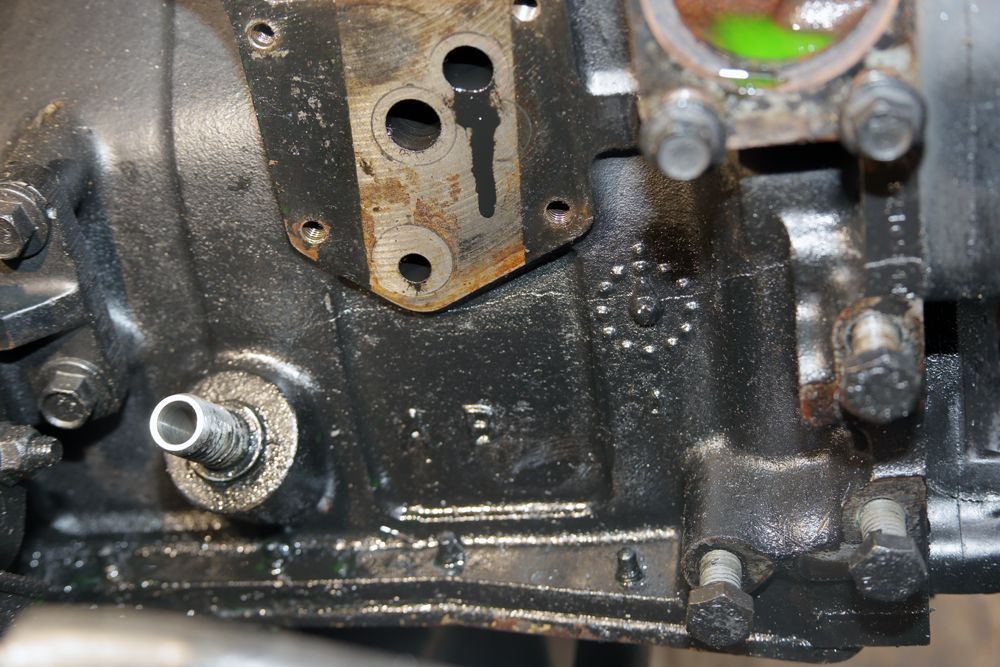

I'm initially thinking a rod bearing parted ways but, it does look like the crankshaft was trying to get out.

Taking things apart, I did notice the gearcase cover's crankshaft seal appeared like it was severely wallowed-out with a corresponding very wide groove in the associated speedy-sleeve on the crankshaft.

Still got to pull the engine to see inside.

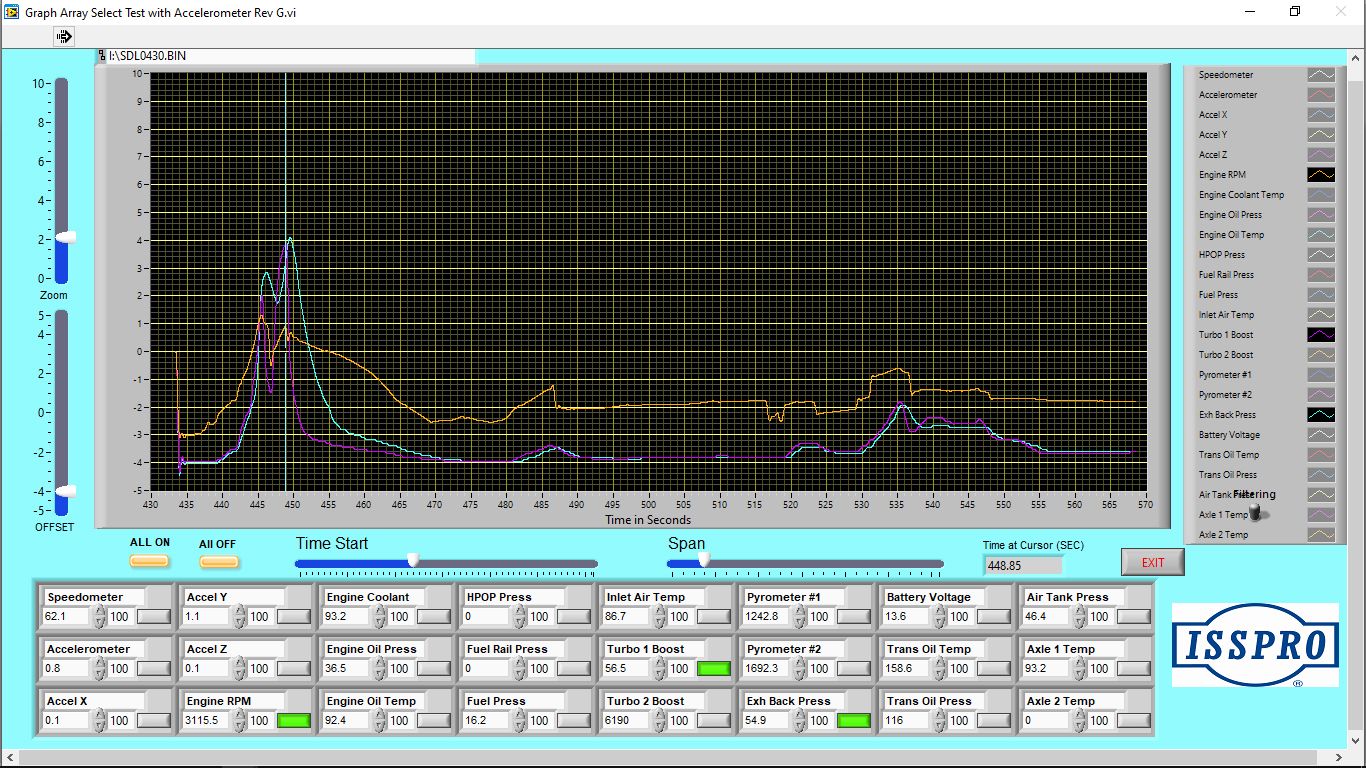

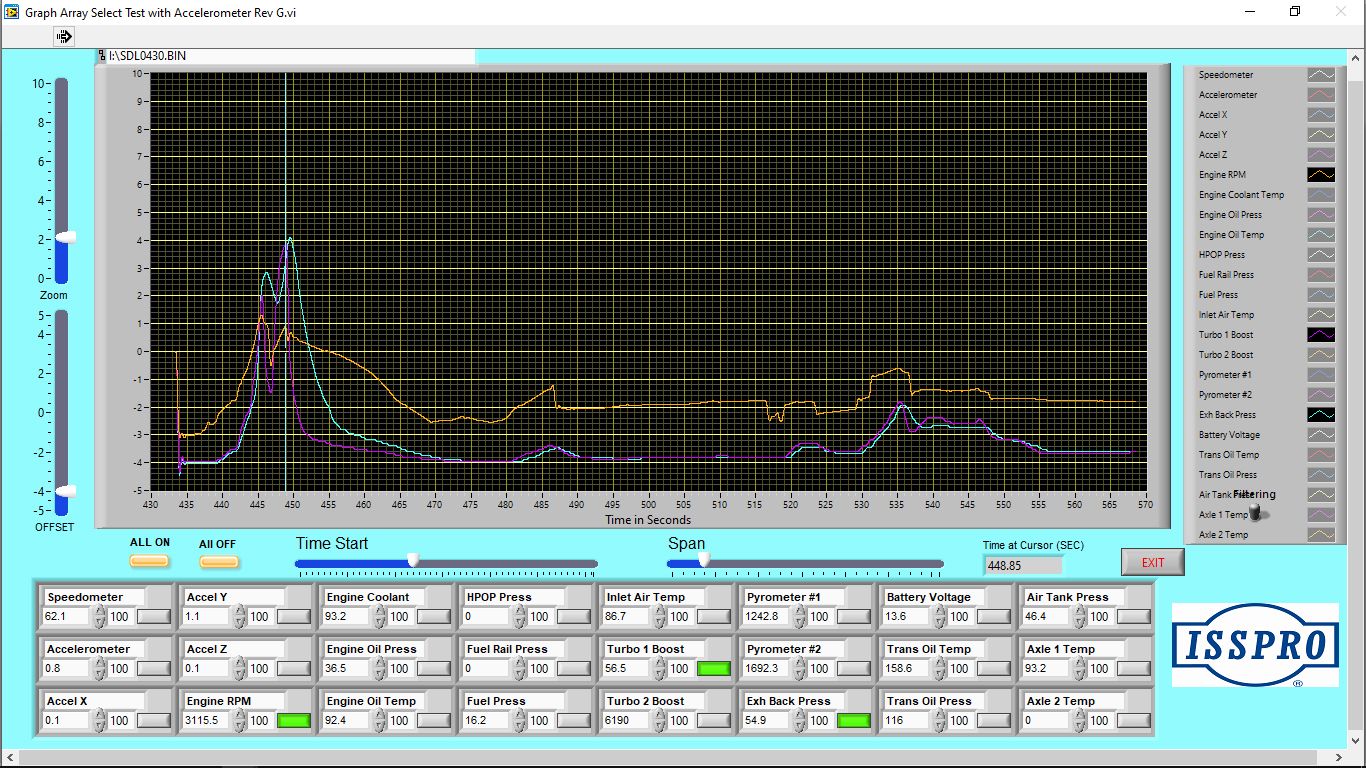

The back-pressure always appeared very reasonable. Being very critical of it, it's always spiked a little with letting off the throttle just after a good pull. Otherwise, the back-pressure matched/lagged behind the boost.

If you can make it out:

- Orange is engine RPM.

- Purple is that seen at the secondary's outlet.

- Lt Blue is back-pressure

'93 5.9 12V. Well flowing head (195in/220out), 188/220 cam, recently two S362 into one S362 (150ish lb/min). 12mm VE w/working dynamic-timing, honed 5x.018 (4.7ltr/min). All the other mess.

Cranked it up to go and make a dyno appointment. Noticed the oil pressure was a little lower than normal. Oil level good. On the way home I heard what initially sounded like I'd air-bound an injector (it's a VE thing). Within a moment, that apparent miss turning into a very pronounced stomping in the block. No oil pressure. Oil level's still good.

The engine still ran. The hardness of the stomp followed the throttle.

I'm initially thinking a rod bearing parted ways but, it does look like the crankshaft was trying to get out.

Taking things apart, I did notice the gearcase cover's crankshaft seal appeared like it was severely wallowed-out with a corresponding very wide groove in the associated speedy-sleeve on the crankshaft.

Still got to pull the engine to see inside.

The back-pressure always appeared very reasonable. Being very critical of it, it's always spiked a little with letting off the throttle just after a good pull. Otherwise, the back-pressure matched/lagged behind the boost.

If you can make it out:

- Orange is engine RPM.

- Purple is that seen at the secondary's outlet.

- Lt Blue is back-pressure

Last edited by a moderator:

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 11,995

So how'd it do on the dyno?

Chris

Chris

Empty_Pockets

Undercover Epa agent

- Joined

- Oct 5, 2016

- Messages

- 870

So how'd it do on the dyno?

Chris

That was my question too. Hope it atleast did well before it let go. Sounds like it didnt owe you a thing though haha

BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

I had just set up the dyno appointment for a week ahead. The thought was that would give me a week to identify and address any stupid stuff beforehand (a known issue in my past).

Anyhoo, I'd just finished a new transmission build and, I'd just realized that I could program the Compushift to have the OverDrive and converter lockup below 35MPH (for the dyno). So, rolling along locked, in OD at 35MPH, and holding the brakes, I built the boost up to 25psig and let it eat.

Then it went to stomping. :doh:

Anyhoo, I'd just finished a new transmission build and, I'd just realized that I could program the Compushift to have the OverDrive and converter lockup below 35MPH (for the dyno). So, rolling along locked, in OD at 35MPH, and holding the brakes, I built the boost up to 25psig and let it eat.

Then it went to stomping. :doh:

Last edited:

BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

That thing was on the verge of splitting the block at the main studs. Just means you gotta go bigger now!

It's my understanding that the '93 5.9 12v has 14mm mains stock/OEM.

SKYNYRD

"Drunkard"

- Joined

- May 14, 2007

- Messages

- 5,668

It's my understanding that the '93 5.9 12v has 14mm mains stock/OEM.

12mm or 14mm doesn't really matter, it looks like the block split above where the top end of the main studs are located. I have seen a number of blocks split at the same location.

BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

That particular plot is just to illustrate the boost/back-pressure relationship.Edit, see the setup now.

Am I reading the graph right that the excitement happened below 1k rpm?

Typically, I'm around 2000 engine RPM @ 25psig boost as the lights come down.

Last edited: