murphy41

New member

- Joined

- Jan 22, 2009

- Messages

- 1,624

Jesus it sure would be nice to have a shop. I hate living in an apartment, lol I'd gladly buy a little tonka toy just so I could pull my engine and do all of this legit .. It'd be fun for me too lol

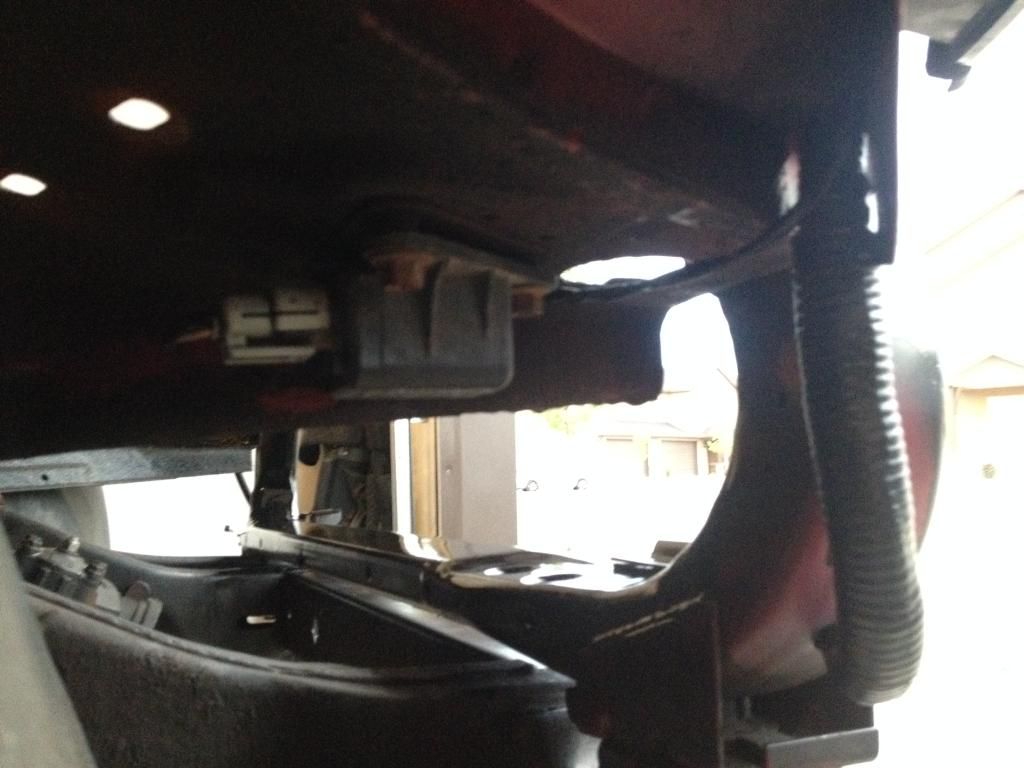

I've been fortunate enough to use the girlfriends dads shop at his house. I'm only 24 and don't have my own house yet either. The house I rent with my girlfriend and my buddy and his chick won't quite fit my truck in the garage. It'll fit his RCLB with just barely enough room to get around it. But I try to help her dad around the house and yard as much as I can, and his trucks. So he let me use it. But it's outside right now till the motor is done and ready to install cause I didn't want to leave it in his shop not doing anything. Cause he uses it for his two plow trucks to unthaw.