BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

So, I broke my block and am pulling stuff out of it in hopes of reusing it.

I got 188/220 steel cam and 24v lifters from Zach in Feb of 2012. I'd been running his 110 (?) valve-springs with his 1st stage HD (whatever) pushrods.

Anyhoo, pulling the cam out this afternoon and standing back and looking at stuff reveals things like:

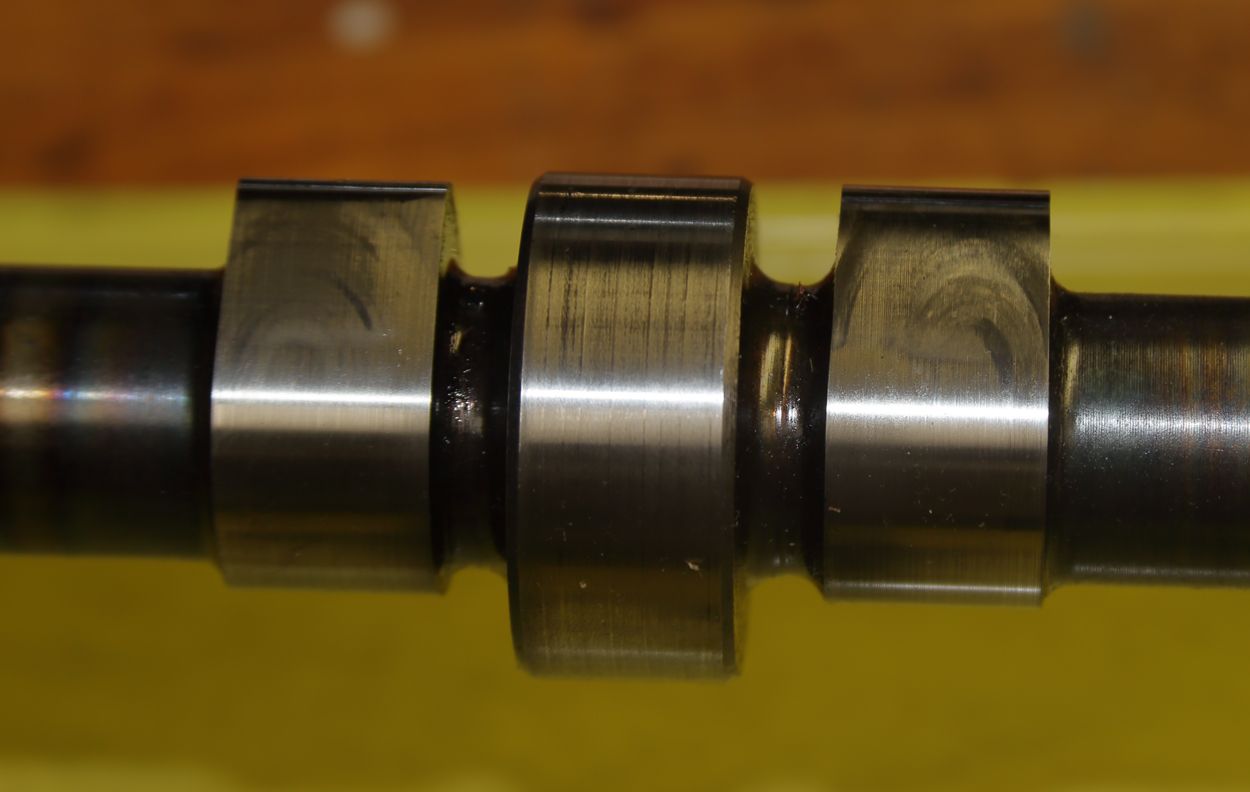

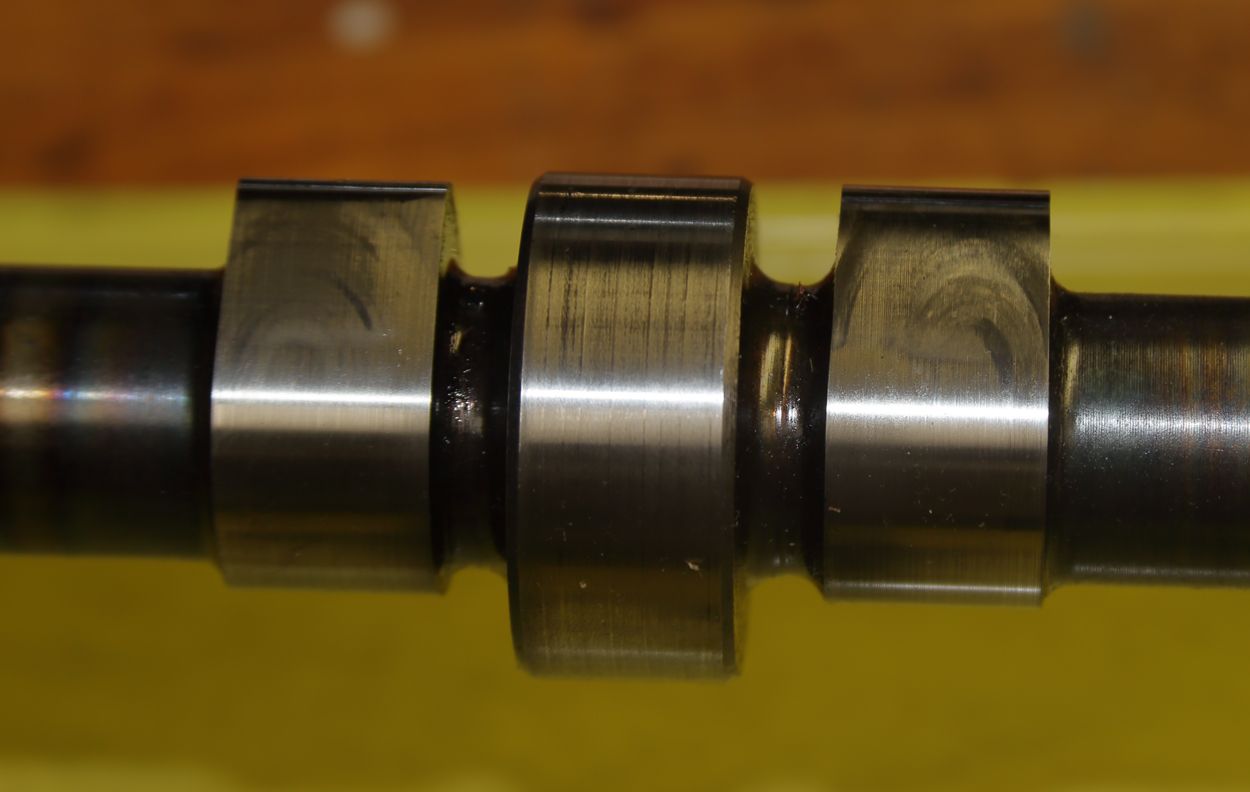

- The lobes of the cam have a surface of anywhere from smooth to heavily cratered (?)

- The lifters smooth to heavy cratering (?)

1 - Exhaust . . . .

3 - Intake . . . .

5 - Exhaust . . .

All of the lobes present with shadows on the ramps . . .

I'm gonna go out on a limb and say I've gotten my monies worth from the rods, huh? Some have grown nipples.

I've always run a good dose of the ZDDP supplement stuff with Rotela. Ya reckon there's any salvaging of that cam?

Crap! :doh:

I got 188/220 steel cam and 24v lifters from Zach in Feb of 2012. I'd been running his 110 (?) valve-springs with his 1st stage HD (whatever) pushrods.

Anyhoo, pulling the cam out this afternoon and standing back and looking at stuff reveals things like:

- The lobes of the cam have a surface of anywhere from smooth to heavily cratered (?)

- The lifters smooth to heavy cratering (?)

1 - Exhaust . . . .

3 - Intake . . . .

5 - Exhaust . . .

All of the lobes present with shadows on the ramps . . .

I'm gonna go out on a limb and say I've gotten my monies worth from the rods, huh? Some have grown nipples.

I've always run a good dose of the ZDDP supplement stuff with Rotela. Ya reckon there's any salvaging of that cam?

Crap! :doh:

Last edited: