Chris Tobin

New member

This does not include the C2 half of the engine harness, passenger side battery wiring, grid heater wiring, door wiring, or cab wiring. I'm guessing there is somewhere around 50 pounds of wiring in a regular cab.

This was one of three piles of tape and loom that was discarded.

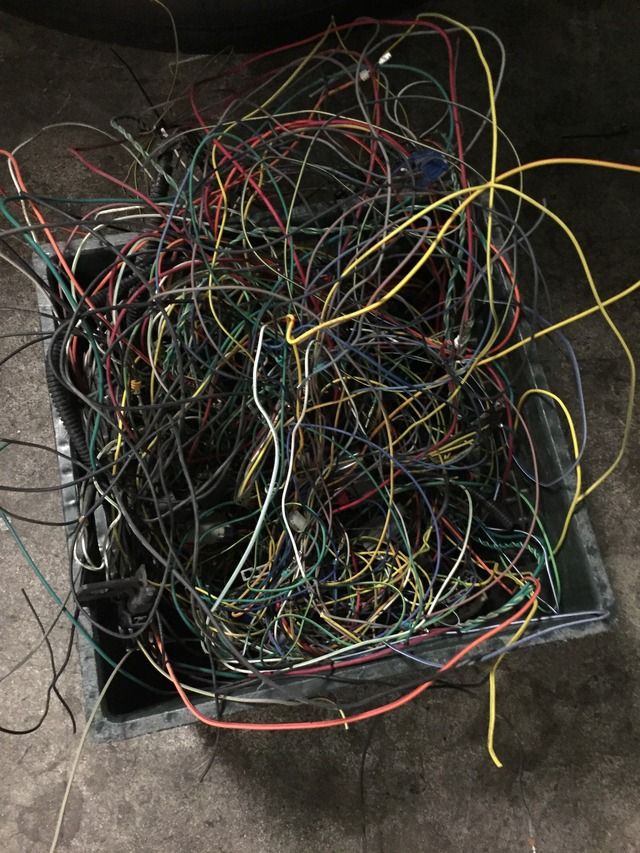

This is only a fraction of the wiring that was removed from the harnesses.

My fingers are a little raw but the wiring harness looks much cleaner now. I'm waiting on some more wire wrap to show up so I can finish it up. The new and improved bumper to bumper harness weighs 7 lbs. Best of all, I have a much better understanding of my truck's electrical system now. Big thanks to Chase L. and Erick for some help when I got hung up.

Wow, now we know why the OEM's are simplifying the harnesses and running data busses and such to reduce weight.

That is a huge reduction in weight from just simplifying the harness!!! Good work!!!