You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

converting 99 24 valve to 12 valve problem

- Thread starter slrrls

- Start date

BigPapa

Truckless

- Joined

- Jan 25, 2008

- Messages

- 5,086

1) Here ya go:

’97 12V

- Violet/White – Pin A17 on PCM (5V Supply)

- Black/Light Blue – Sensor Ground

- Gray/Black – Pin A8 on PCM (Engine Speed Sensor Signal)

’99 24V

- Violet/White – Pin 3 on ECM (5V Supply)

- Black/Dark Blue – Pin 4 on ECM (Sensor Ground)

- Gray – Pin 17 on ECM (Crankshaft Position Sensor Signal)

2) Yes, those are the oil pressure sensors. I relocated mine to the top of the oil filter head where the 1/8" pipe plug is due to easier accessability.

3) The one with the probe.

4) My ECM is currently hanging from a stout piece of wire on one of the master cylinder bolts just to keep it off the starter. I plan to fab a bracket to hang basically in the same place from both master cylinder bolts and bolt the ECM to the bracket.

5) kleann's got it on the return line.

He's also correct on the MAP sensor. Not necessary in our application except to keep from throwing a code.

’97 12V

- Violet/White – Pin A17 on PCM (5V Supply)

- Black/Light Blue – Sensor Ground

- Gray/Black – Pin A8 on PCM (Engine Speed Sensor Signal)

’99 24V

- Violet/White – Pin 3 on ECM (5V Supply)

- Black/Dark Blue – Pin 4 on ECM (Sensor Ground)

- Gray – Pin 17 on ECM (Crankshaft Position Sensor Signal)

2) Yes, those are the oil pressure sensors. I relocated mine to the top of the oil filter head where the 1/8" pipe plug is due to easier accessability.

3) The one with the probe.

4) My ECM is currently hanging from a stout piece of wire on one of the master cylinder bolts just to keep it off the starter. I plan to fab a bracket to hang basically in the same place from both master cylinder bolts and bolt the ECM to the bracket.

5) kleann's got it on the return line.

He's also correct on the MAP sensor. Not necessary in our application except to keep from throwing a code.

Last edited:

slrrls

Water fuel 1st diesel 2nd

- Joined

- Jun 30, 2012

- Messages

- 135

Good to know, I'm rerouting my plug.

I looked on the title and the truck is actually a 97 and the engine is a 96.

My air sensor plugs were the same for the 99 and the 97 so I just plugged in there. Now I'm just using two plugs at the price of 50 bucks for adapters, he haw.

I looked on the title and the truck is actually a 97 and the engine is a 96.

My air sensor plugs were the same for the 99 and the 97 so I just plugged in there. Now I'm just using two plugs at the price of 50 bucks for adapters, he haw.

slrrls

Water fuel 1st diesel 2nd

- Joined

- Jun 30, 2012

- Messages

- 135

Check out the photos of the oil sensor plug on the harness and see if I have this correct please.

I didn't realize there was an identical plug so close to the ecm.

I clipped the plug wire closest to the ecm.

but not to much further away is a junction and another plug. Then I found another identical plug very near the 24v injector pump harness. So that is three plugs total that are the same type as the oil sensor plug.

I didn't realize there was an identical plug so close to the ecm.

I clipped the plug wire closest to the ecm.

but not to much further away is a junction and another plug. Then I found another identical plug very near the 24v injector pump harness. So that is three plugs total that are the same type as the oil sensor plug.

Attachments

slrrls

Water fuel 1st diesel 2nd

- Joined

- Jun 30, 2012

- Messages

- 135

well the light blue looks more like a dingy white.

It is the first plug from the ecu and the oil sensor is literally right next to the ecu on the 24v so I'm going to go with this is it.

The 3rd adapter I found was the same was the timing sensor that hides behind the injector pump and it had an orange as well. I soldered into that one before I realized there were two more.

It is the first plug from the ecu and the oil sensor is literally right next to the ecu on the 24v so I'm going to go with this is it.

The 3rd adapter I found was the same was the timing sensor that hides behind the injector pump and it had an orange as well. I soldered into that one before I realized there were two more.

Attachments

Last edited:

BigPapa

Truckless

- Joined

- Jan 25, 2008

- Messages

- 5,086

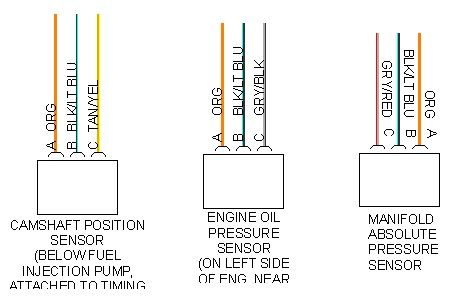

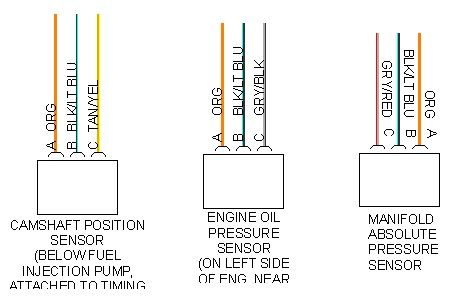

It's a black wire with a light blue stripe. The only other sensors with an orange wire is the cam sensor and MAP sensor. Here's all the sensor connectors with an orange wire.

From what you're saying you're looking at the cam sensor connector with the Tan wire with a Yellow stripe. The distinguishing wire for the oil pressure sensor is the Gray wire with a Black stripe.

From what you're saying you're looking at the cam sensor connector with the Tan wire with a Yellow stripe. The distinguishing wire for the oil pressure sensor is the Gray wire with a Black stripe.

Last edited:

slrrls

Water fuel 1st diesel 2nd

- Joined

- Jun 30, 2012

- Messages

- 135

Thank you for taking the time with these diagrams.

I'll double check tomorrow that I have the correct wire.

I was looking at the tone ring and the sensor today.

The sensor is as big around as a thumb so I tend to thing it has a wide range of space to read from instead of just a small slim space in the middle of the sensor.

The ring is really close to the harmonic balance and I was wondering how close the tolerance is for the sensor reading off of the tone ring?

Is it possible it can pick up the notches in the harmonic balance so as to get interference if it is dead center on the har. balance or would it even matter at all if it reads from both the ring and the har. balance?

I'll double check tomorrow that I have the correct wire.

I was looking at the tone ring and the sensor today.

The sensor is as big around as a thumb so I tend to thing it has a wide range of space to read from instead of just a small slim space in the middle of the sensor.

The ring is really close to the harmonic balance and I was wondering how close the tolerance is for the sensor reading off of the tone ring?

Is it possible it can pick up the notches in the harmonic balance so as to get interference if it is dead center on the har. balance or would it even matter at all if it reads from both the ring and the har. balance?

BigPapa

Truckless

- Joined

- Jan 25, 2008

- Messages

- 5,086

slrrls,

The 24V crank sensor won't read both. I have my sensor centered on the tone wheel.

kleann,

Your talking about a different number of pulses. I think the cam sensor makes 1 or 2 pulses per rpm where the crank is making 35. Is there a tone ring on the cam? How many teeth?

What's this "Location: Africa" stuff? Where you at?

The 24V crank sensor won't read both. I have my sensor centered on the tone wheel.

kleann,

Your talking about a different number of pulses. I think the cam sensor makes 1 or 2 pulses per rpm where the crank is making 35. Is there a tone ring on the cam? How many teeth?

What's this "Location: Africa" stuff? Where you at?

Chevycummins

Bad case of Tinkeritis!

- Joined

- Jul 15, 2008

- Messages

- 3,488

The tone ring on the cam has like 80 holes punched out. Maybe not that many but has several lol

Chevycummins

Bad case of Tinkeritis!

- Joined

- Jul 15, 2008

- Messages

- 3,488

Hey bigpapa do you think using a cam gear with a tone ring and cam sensor plugged into the crank sensor wiring connection would work?

I think You could fab up a mount and use it that way. I would just use the 24v cam and get the adapter that goes on the back of the gear case like I did.

kleann

VP44 pwr

- Joined

- Aug 23, 2008

- Messages

- 4,388

slrrls,

The 24V crank sensor won't read both. I have my sensor centered on the tone wheel.

kleann,

Your talking about a different number of pulses. I think the cam sensor makes 1 or 2 pulses per rpm where the crank is making 35. Is there a tone ring on the cam? How many teeth?

What's this "Location: Africa" stuff? Where you at?

Africa is a joke. I am talking about the tone ring on the 2001 and 2002 trucks, since they dont use a crank sensor.

BigPapa

Truckless

- Joined

- Jan 25, 2008

- Messages

- 5,086

kleann,

I'm not sure on your situation. I just don't have any experience with it. I would think that if the ECM is looking for signal from the cam sensor and not a crank sensor, you would have to run the cam sensor and the proper cam/gear. You could run the 24V cam if you don't use the mechanical 12V lift pump. I don't know about putting a 24V gear on a 12V cam.

I'm not sure on your situation. I just don't have any experience with it. I would think that if the ECM is looking for signal from the cam sensor and not a crank sensor, you would have to run the cam sensor and the proper cam/gear. You could run the 24V cam if you don't use the mechanical 12V lift pump. I don't know about putting a 24V gear on a 12V cam.

slrrls

Water fuel 1st diesel 2nd

- Joined

- Jun 30, 2012

- Messages

- 135

If I have these plugs right then looking at the pictures each has a different P.E.D number.

Crank sensor plug = pur/wh gray blk and the plug says 12* P.E.D.

Oil sensor plug = orange blk/LT BlU the plug says 10* P.E.D.

Cam sensor plug = orang blk/LT BLU Tan/Yel plug says 2* P.E.D.

Can you double check for me? I have the oil and cam sensor plugs lenghtened already but going to wait till I know the crank is correct before I solder.

Thanks

Crank sensor plug = pur/wh gray blk and the plug says 12* P.E.D.

Oil sensor plug = orange blk/LT BlU the plug says 10* P.E.D.

Cam sensor plug = orang blk/LT BLU Tan/Yel plug says 2* P.E.D.

Can you double check for me? I have the oil and cam sensor plugs lenghtened already but going to wait till I know the crank is correct before I solder.

Thanks