Joesixpack

Pull'n it.

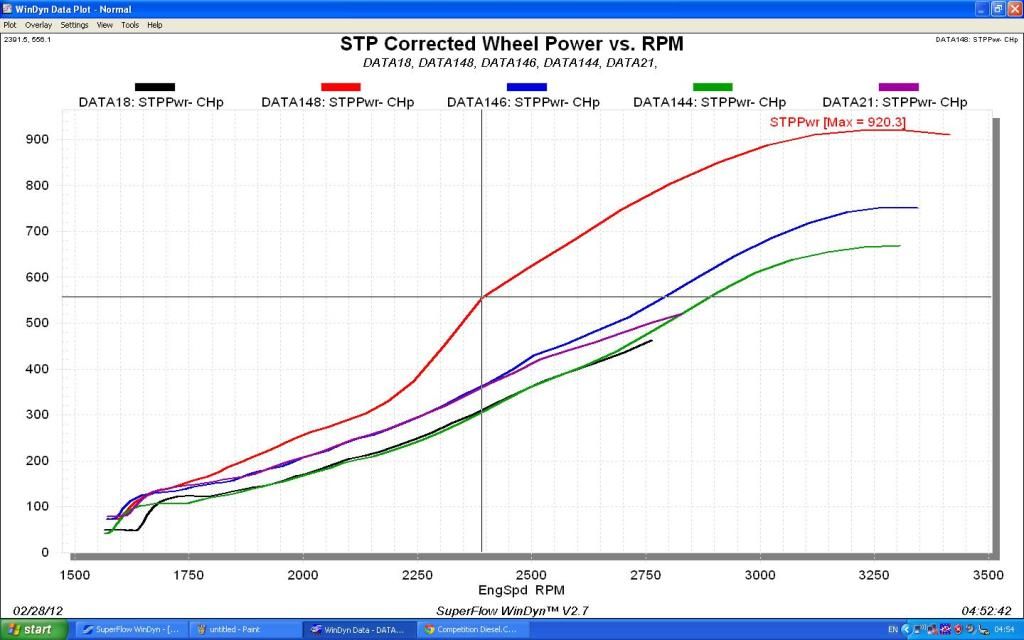

So I made a few more pulls this evening, again I looked back and found some short inertia+load pulls with the stock cam. (They were just quick test runs to check loading and I pulled the throttle before they were complete but the data is still relevant lower rpm spooling)

Data 18 Black 10% Load Stock cam

Data 144 Green 10% Load 188/220

Data 21 Purple 15% Load Stock cam

Data 146 Blue 15% Load 188/220

Data 148 Red Hot tune 15% load vs zero load from before. (I need at least 30%) to pull my peak HP.

AGAIN even on loaded tests the cam change alone is making absolutely no change in spool. Don't know what to say but its just not there.

The hot spooling tune made a huge difference.

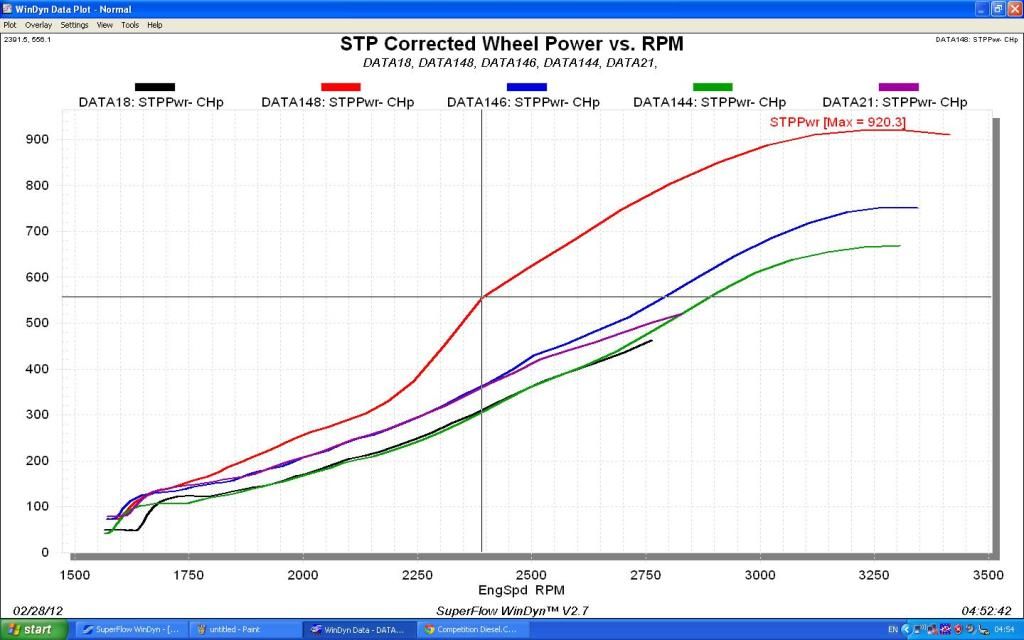

Data 18 Black 10% Load Stock cam

Data 144 Green 10% Load 188/220

Data 21 Purple 15% Load Stock cam

Data 146 Blue 15% Load 188/220

Data 148 Red Hot tune 15% load vs zero load from before. (I need at least 30%) to pull my peak HP.

AGAIN even on loaded tests the cam change alone is making absolutely no change in spool. Don't know what to say but its just not there.

The hot spooling tune made a huge difference.

Last edited: