The V12 Detroit commonrail is game over, looks like the internals are to weak to take the combustion load from a commonrail system. I think the team that run this engine in there semi is going to look for a modern stronger engine.

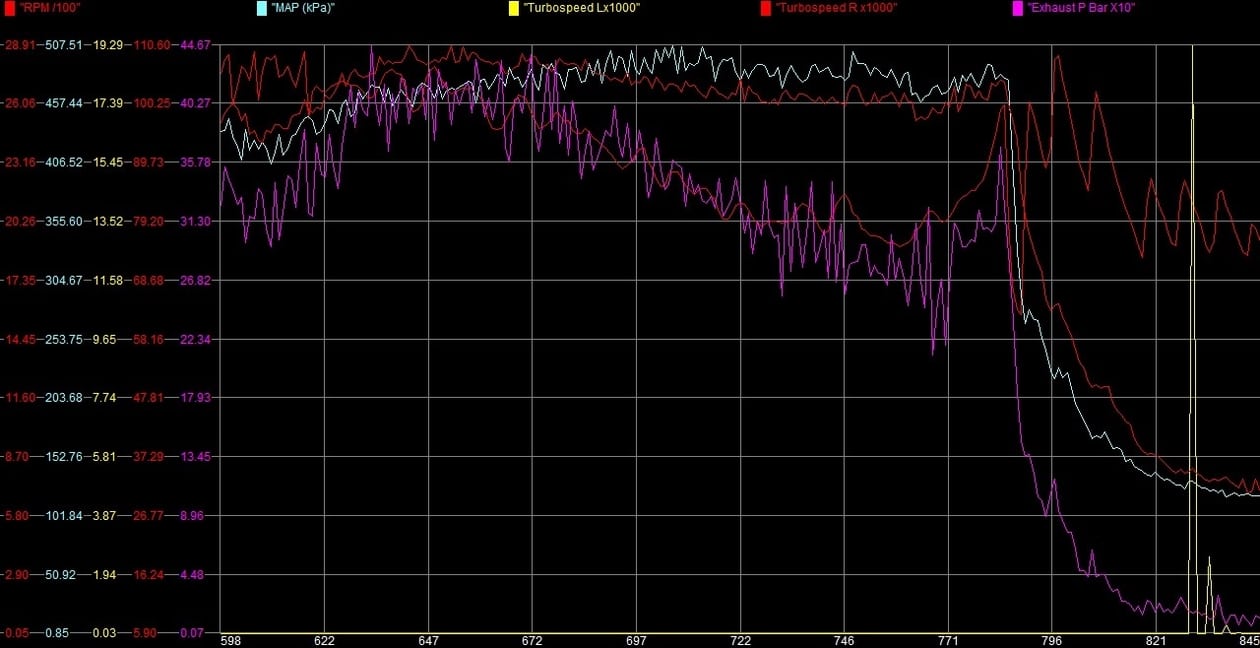

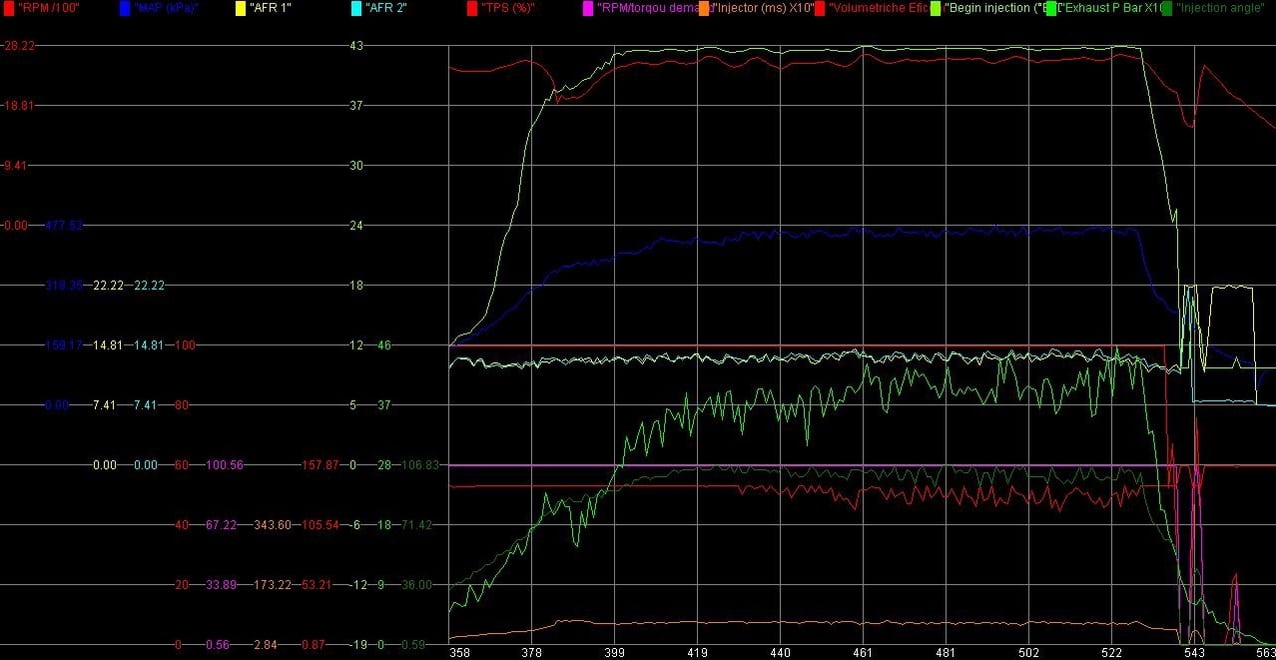

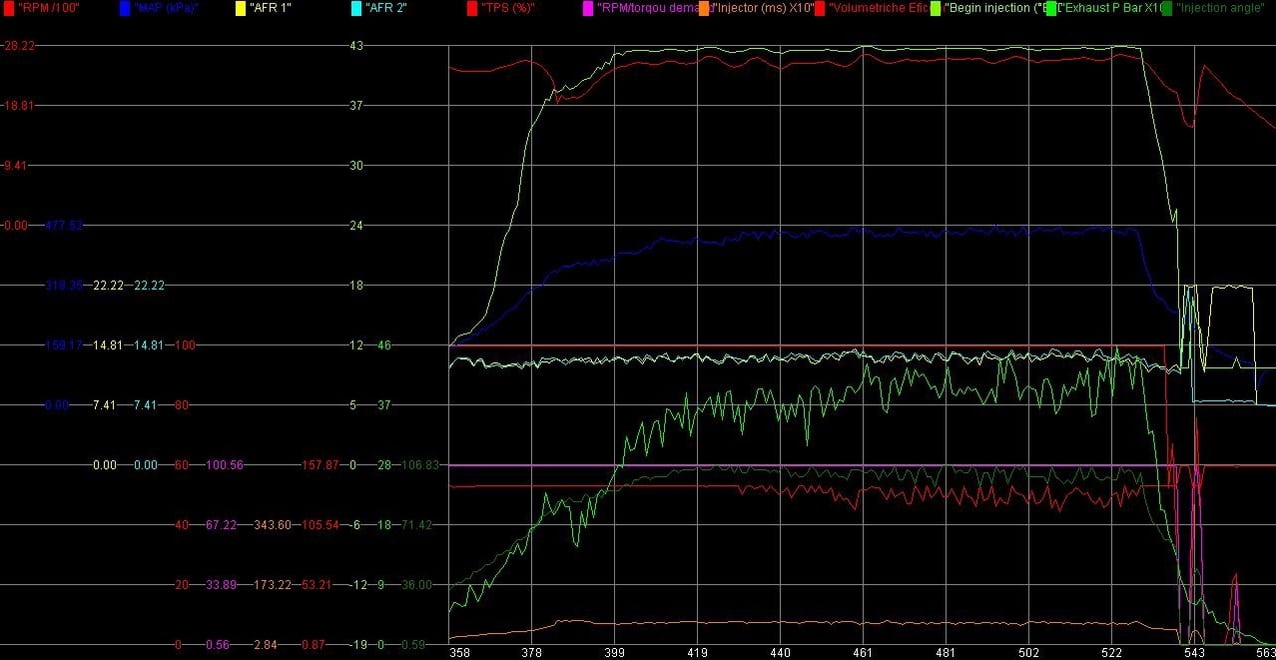

Yesterday we had a bit of bad luck also blowing up a turbocharger in qualification. Interesting could be if there is something in the data that indicate that something is going to happen.

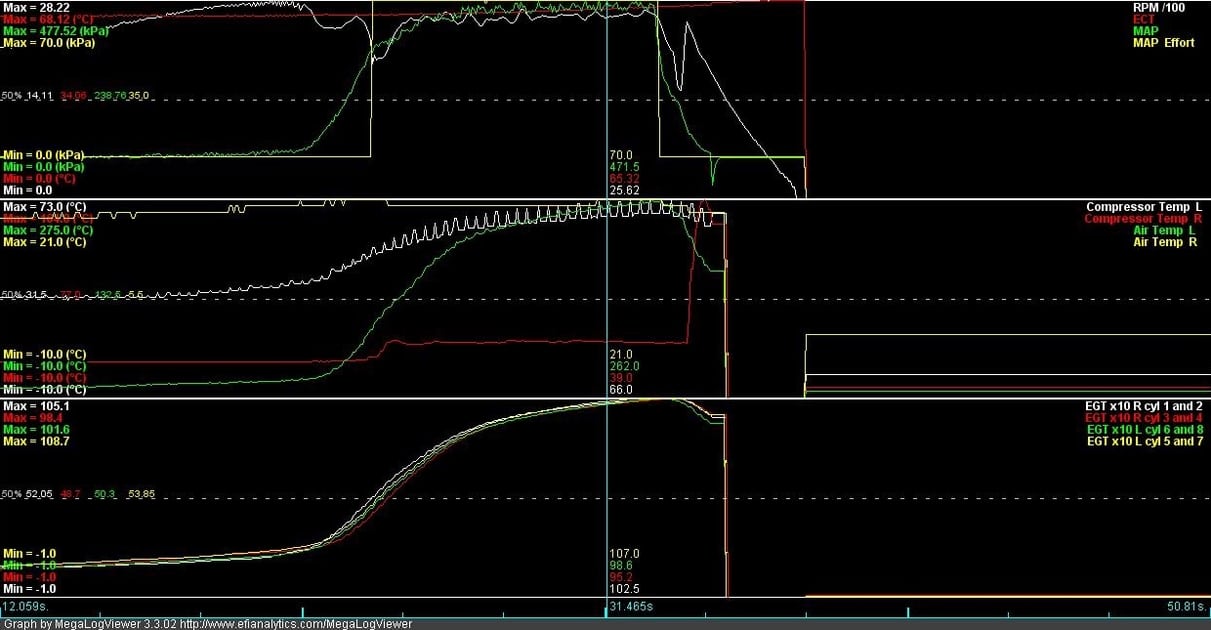

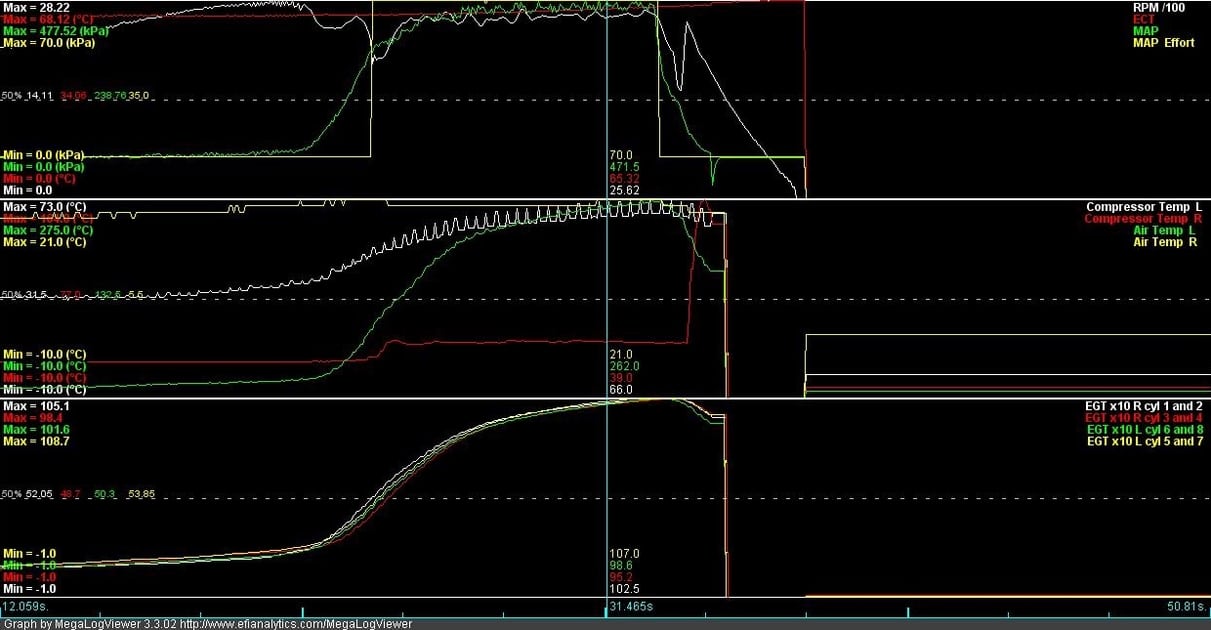

The only thing I could find is the discharge temp from the compressor stays low and than jump up just before blowing up.

We here able to replace the turbocharger just under 16 minutes as we here lucky that the turbine housing was not damaged and where able to complete qualification ending up 3 place after the pull off. We here fist to make a pull and we took the wrong side of the track not able to find good traction not gaining a lot of speed.

[ame="http://www.youtube.com/watch?v=2parj4MY8wc"]Leende 2013 De Manne van Janne 2 semi truck puller pull off 3 place - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=pC8gcjmHU_o"]Leende 2013 De Manne van Janne 2 finale run - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=6WG-_OyRNiU"]Leende 2013 De Manne van Janne 2 kwalificatie turbo kappot - YouTube[/ame]

Yesterday we had a bit of bad luck also blowing up a turbocharger in qualification. Interesting could be if there is something in the data that indicate that something is going to happen.

The only thing I could find is the discharge temp from the compressor stays low and than jump up just before blowing up.

We here able to replace the turbocharger just under 16 minutes as we here lucky that the turbine housing was not damaged and where able to complete qualification ending up 3 place after the pull off. We here fist to make a pull and we took the wrong side of the track not able to find good traction not gaining a lot of speed.

[ame="http://www.youtube.com/watch?v=2parj4MY8wc"]Leende 2013 De Manne van Janne 2 semi truck puller pull off 3 place - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=pC8gcjmHU_o"]Leende 2013 De Manne van Janne 2 finale run - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=6WG-_OyRNiU"]Leende 2013 De Manne van Janne 2 kwalificatie turbo kappot - YouTube[/ame]