Update: Icebox Waterbox Build

For the ice/water box that will feed cold fluid to the water/air coolers, Todd started out with sheets of raw Alcoa-produced aluminum:

A nice speed square comes in handy when fabricating square shapes:

That's a Rule 3700 pump that will be used to push fluid through the air/water coolers. It's rated to flow about 3700 GPH, that's just over

61 gallons per minute!

A little more tig practice on those aluminum sheet seams, maybe by the end of the project we'll have that stack of dimes look down.... as long as it doesn't leak, we're happy!

Then Todd finished up adding a port into the

17 gallon water/ice box. What's nice is it fits in the bed right behind the cab and there's still enough space in the stock 8' bed to fit a 4x8 sheet of plywood. This truck is still going to be a frequent street use/ daily driven vehicle so precious bed space will be saved wherever possible.

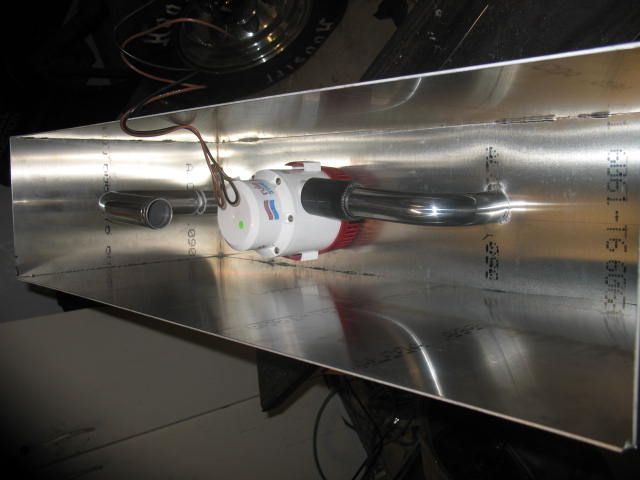

And the Rule 3700 pump is mounted and the cooling outlet and return circuits are plumbed in/out of the box:

Closeup of the Rule 3700 pump, after adding a radiator for long term street use and the cooling lines, we figure the total system capacity will be right at

20 gallons:

As amazing as it may sound, this little Black and Decker jigsaw did all of the aluminum sheet cuts and has been an important part of the fabrication process, who knew a cheap tool would ever hold up to cutting metal!!